A multi-layer composite bush sliding bearing with an oil injection cavity

A multi-layer composite, sliding bearing technology, applied in the directions of shafts and bearings, bearing components, rigid supports of bearing components, etc., can solve the problems of difficult realization, difficult processing, difficult realization of bearings, etc., to improve stability and operation accuracy. , The effect of reducing the processing difficulty and simple bearing structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

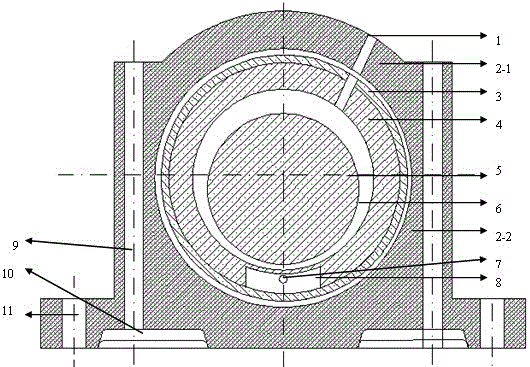

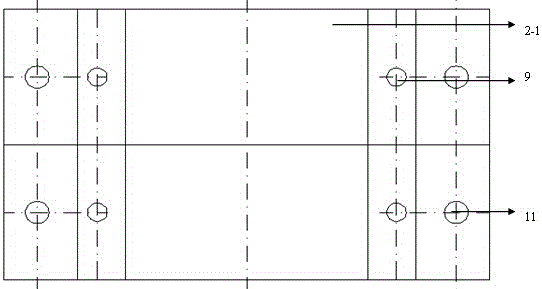

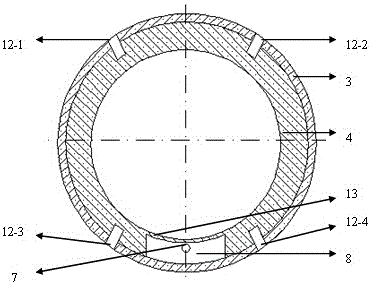

[0025] see figure 1 with figure 2 As shown, the present invention includes three parts: a composite bearing bush with an oil injection cavity, a high-speed rotating journal 5, and a bearing seat for fixing. Among them, the bearing seat is composed of an upper bearing seat 2-1 and a lower bearing seat 2-2 connected below the upper bearing seat 2-1, and the upper bearing seat 2-1 and the lower bearing seat 2-2 are aligned up and down and fixedly connected together Form the bearing housing. When fixing, there are four bolt holes 9 on the upper bearing seat 2-1 and the lower bearing seat 2-2, and the bolt holes 9 are all through holes. Seats 2-2 are fixedly connected together. There are 4 bolt holes 11 on the base of the bearing seat, which are used to fix the whole bearing and transfer the impact of the bearing to the base. There are two symmetrically distributed base grooves 10 at the bottom of the base of the bearing housing. The bolt holes 9 pass through the base grooves ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com