Electric cleaner and suction mouth body

A technology for vacuum cleaners and suction ports, which is applied in the direction of vacuum cleaners, suction nozzles, cleaning equipment, etc., and can solve the problems of increasing costs and not being able to approach

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

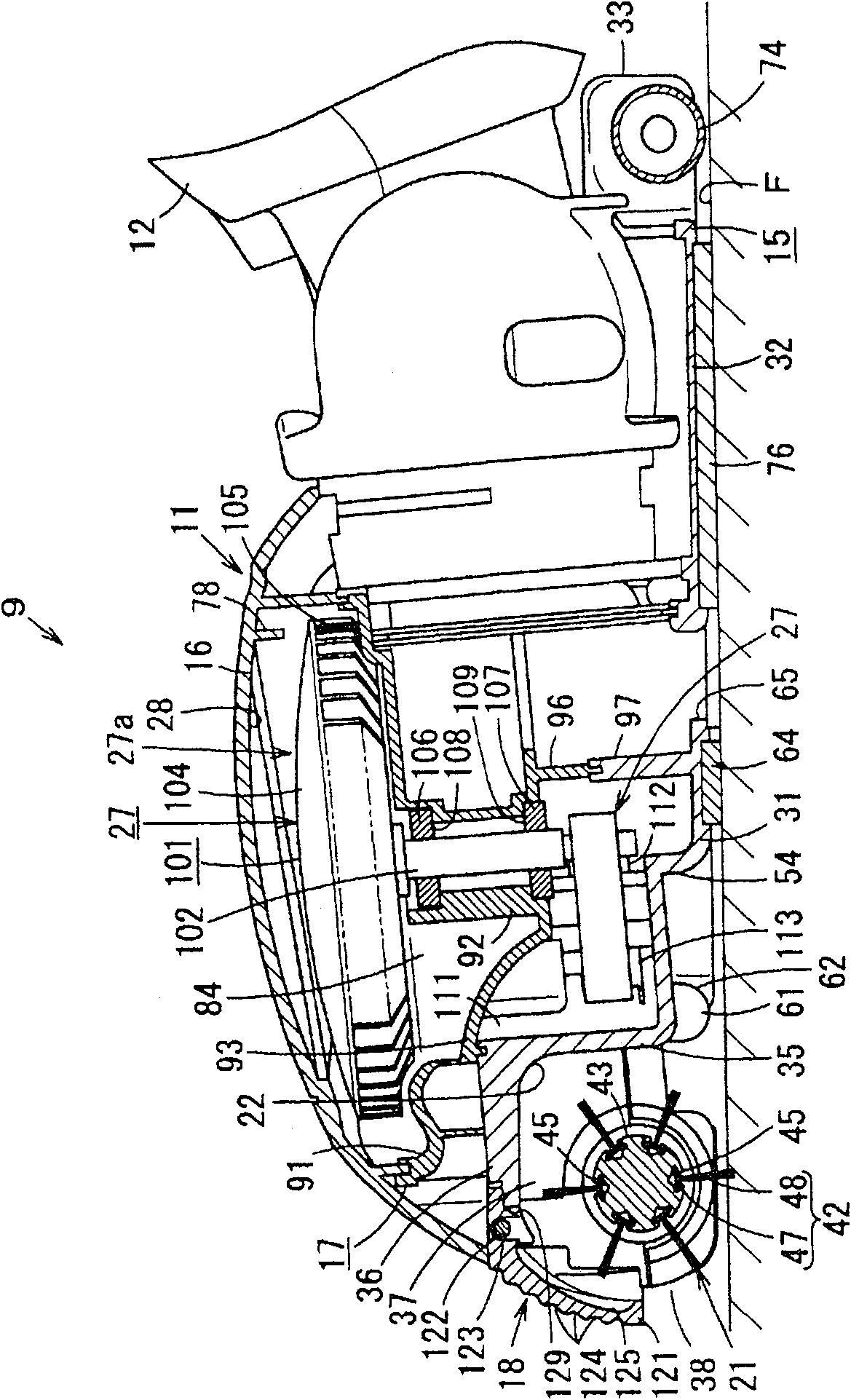

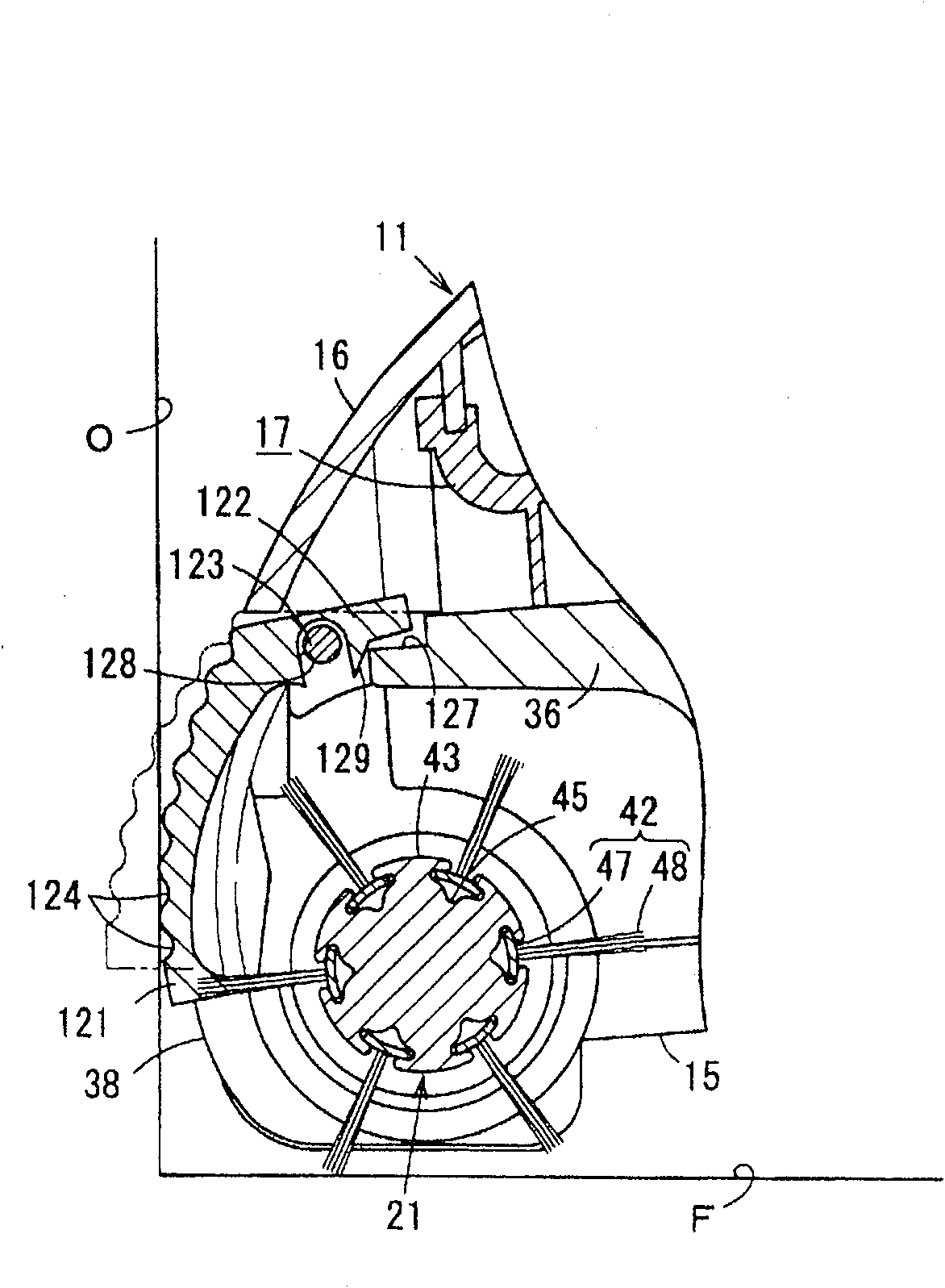

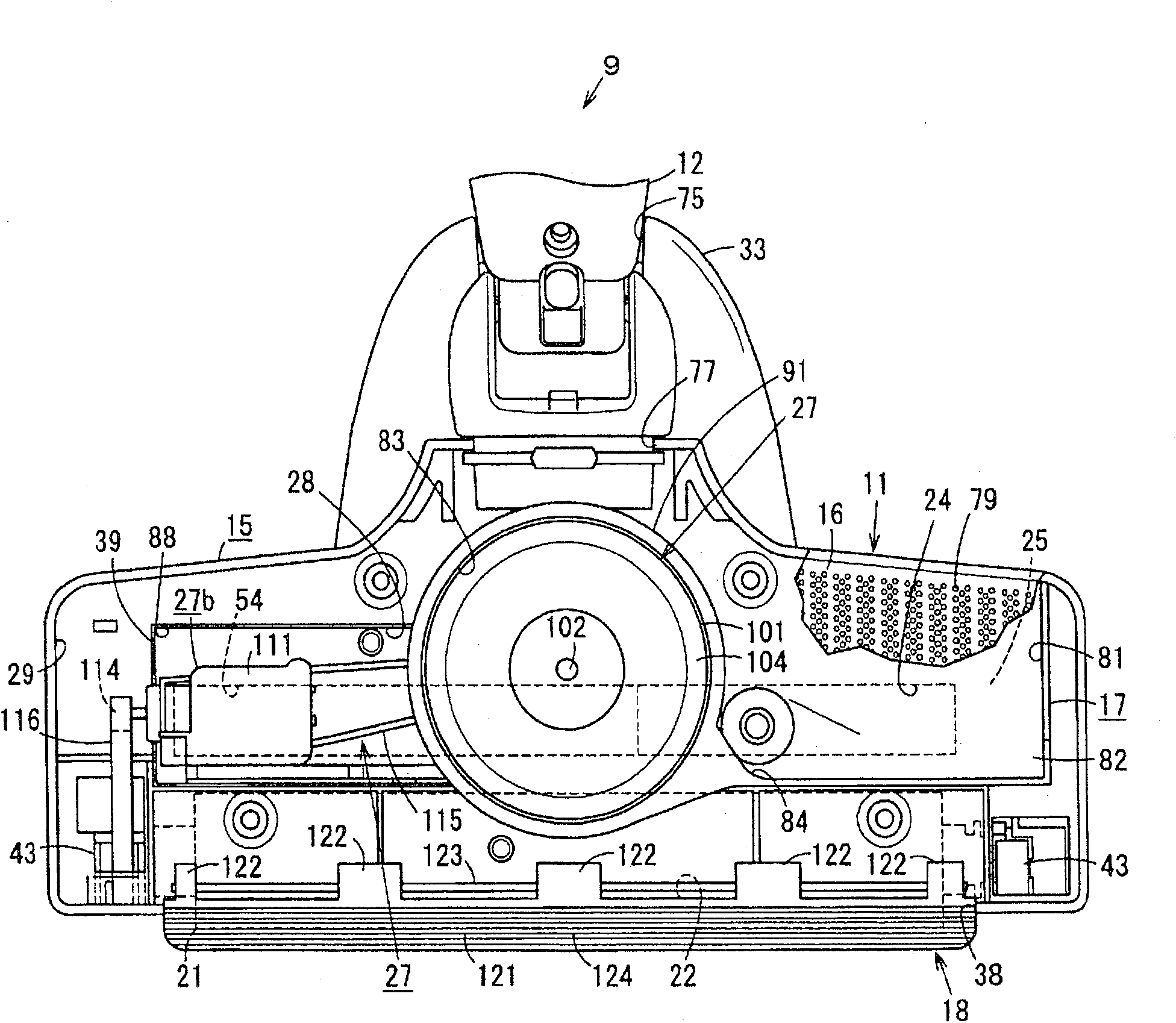

[0035] Below, refer to Figure 1 to Figure 5 The structure of the electric vacuum cleaner which concerns on one Embodiment of this invention is demonstrated.

[0036] exist Figure 5 Among them, 1 is a vacuum cleaner main body, and this vacuum cleaner main body 1 uses a detachable dust collection bag (park) not shown in the figure to collect dust sucked together with the suction wind generated by driving the electric blower 2 accommodated inside. .

[0037] In addition, the vacuum cleaner main body 1 is provided with a main body suction port 3 for sucking air from the outside. A flexible and bendable, elongated, substantially cylindrical hose body 4 is connected to the main body suction port 3 . At the front end of the hose body 4, a portable operation unit 5 capable of selecting an operation mode of the electric blower 2 and the like is provided. On the portable operation part 5, a grip part 6 for the operator to hold when cleaning is protruded toward the base end side, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com