Integrated magnetic pump based on axial dual motor driving

A dual-motor drive, integrated technology, which is applied to components of pumping devices for elastic fluids, non-variable pumps, machines/engines, etc., can solve the problem of large axial dimensions, large axial dimensions of magnetic pumps, Large structure and other problems, to achieve the effect of reducing axial length, small size, and increasing rotational force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

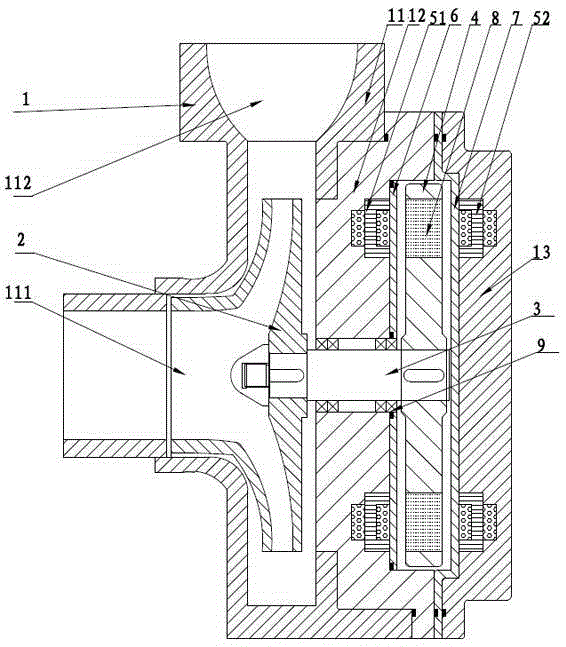

[0022] As shown in the figure, an integrated magnetic pump driven by axial dual motors includes a pump body 1, an impeller 2, a pump shaft 3, a permanent magnet rotor 4 and an electromagnetic stator 5; It is composed of the front casing 11 of the pump body, the middle casing 12 of the pump body and the rear casing 13 of the pump body; the middle casing 12 of the pump body divides the inside of the pump body into two chambers, front and rear; the electromagnetic stator 5 consists of a left stator 51 and a right stator 52 Composition; the front end of the pump body front shell 11 is provided with a fluid inlet 111 communicated with the front chamber, and the top of the pump body front shell 11 is provided with a fluid outlet 112 communicated with the front chamber; the pump body middle shell 12 and the pump body rear shell 13 is oppositely inlaid with a left stator 52 and a right stator 52 arranged circumferentially along the pump shaft 3 .

[0023] There is an impeller 2 in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com