Paper cup machine

A paper cup machine and cup bottom technology, which is applied in the field of paper cup machines, can solve the problems of low product qualification rate, slow production speed, heavy lifting platform load, etc., and achieve the effects of high product qualification rate, fast production speed, and fast cup delivery speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

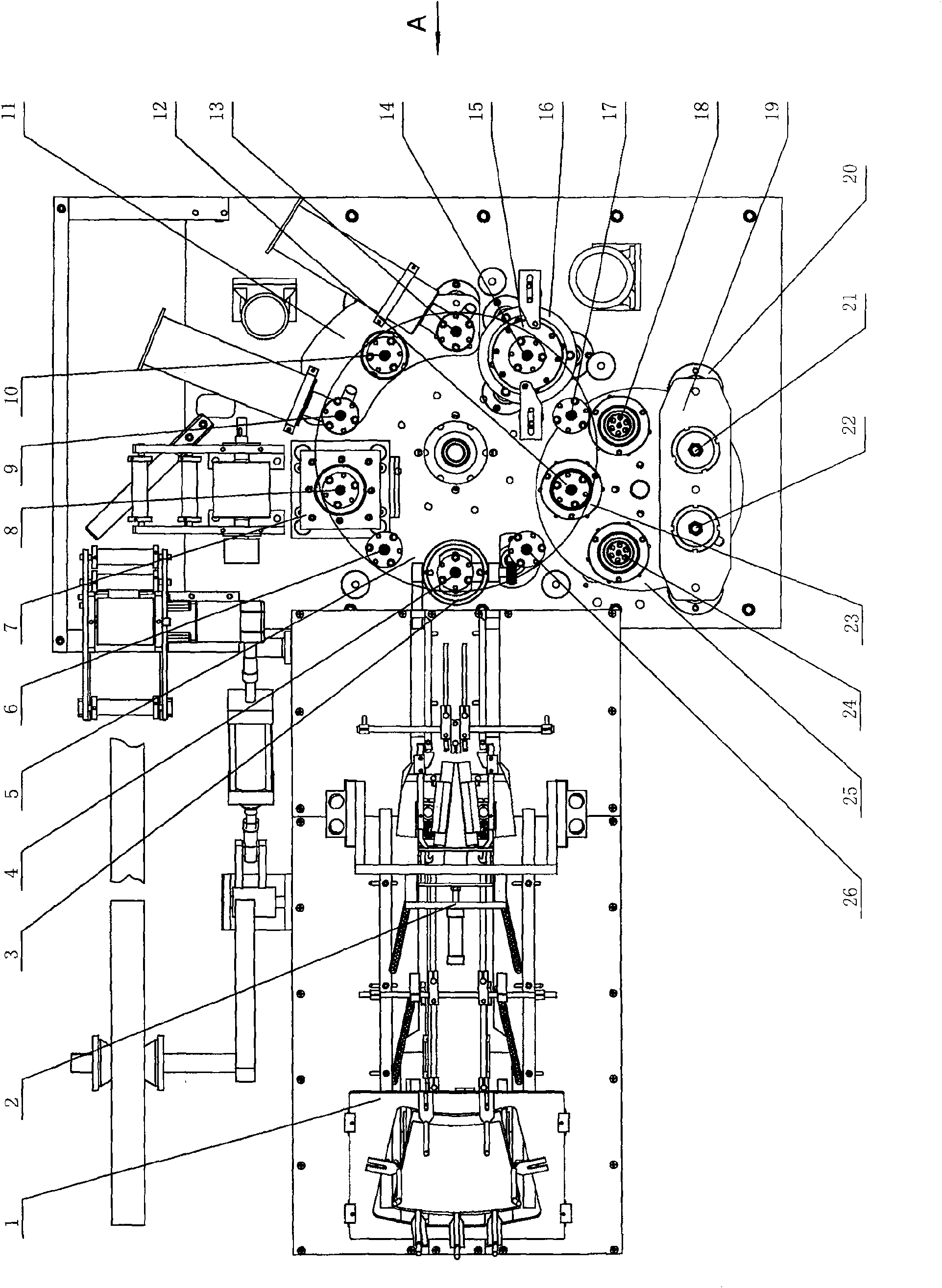

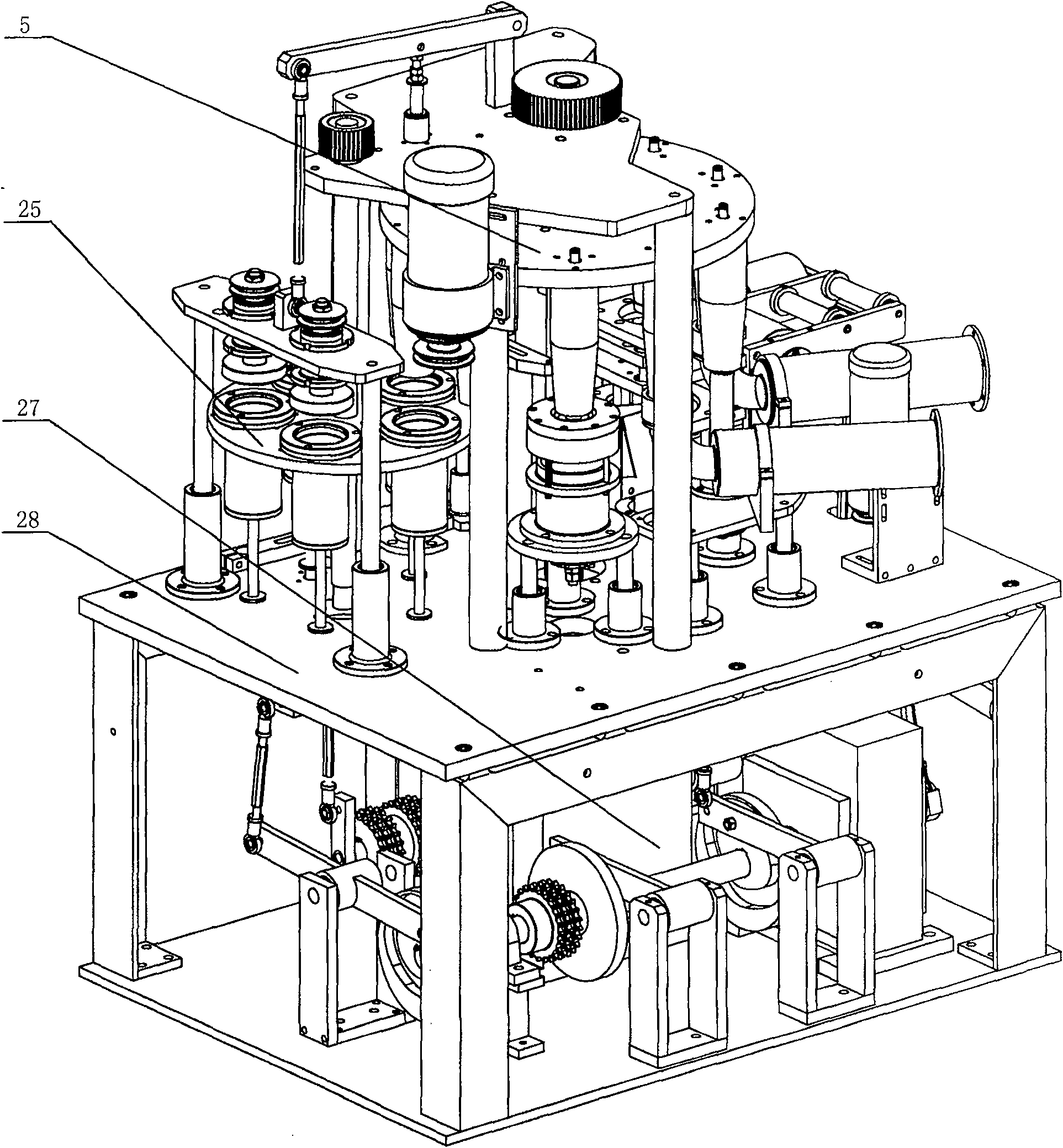

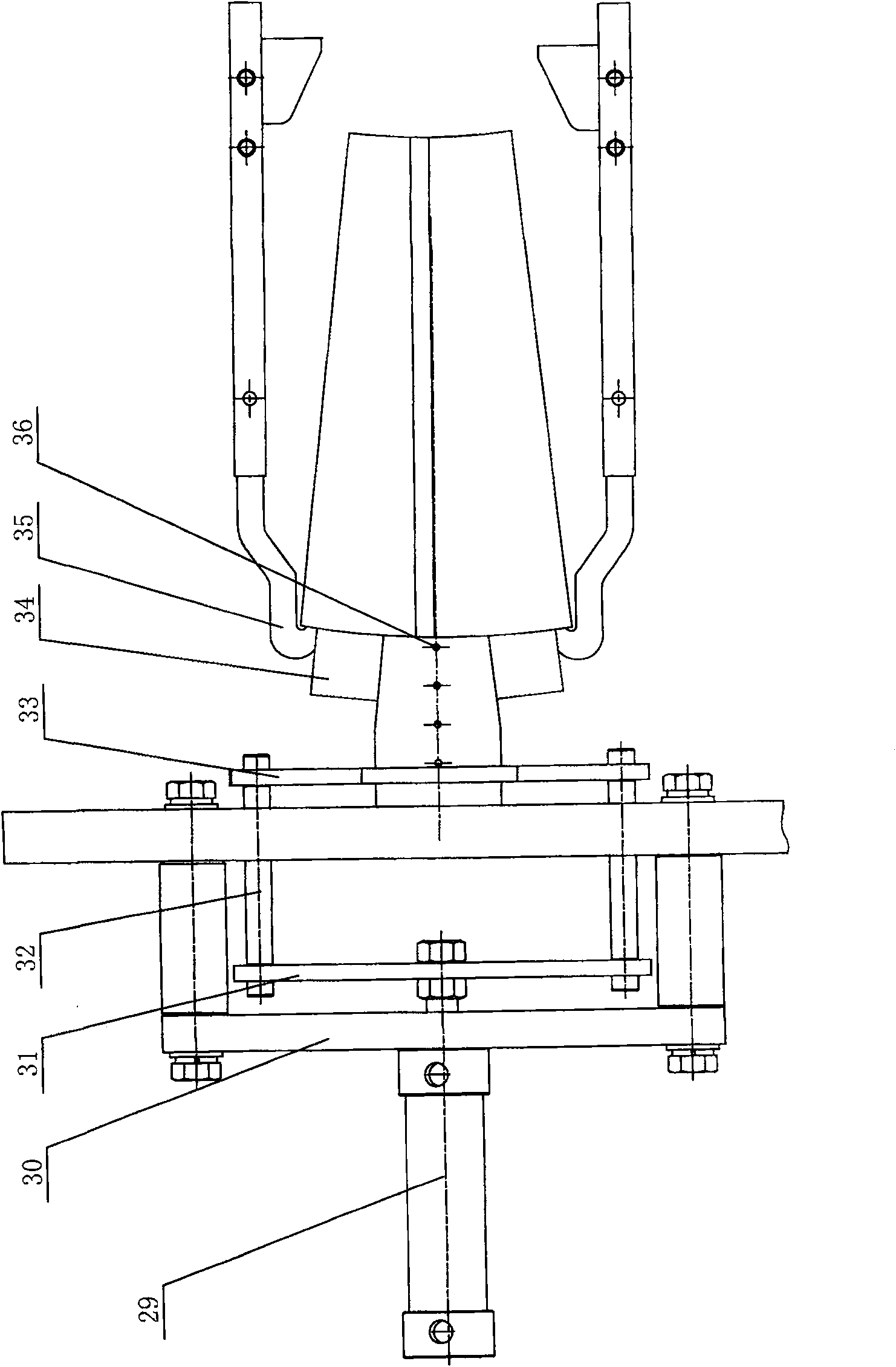

[0019] The accompanying drawings show the technical solution of the present invention and its embodiments, and the relevant details and working principles of the embodiments will be further described below in conjunction with the accompanying drawings.

[0020] Refer to attached figure 1 , 2 , The paper cup machine includes a paper feeding and cutting mechanism 1, a cup body forming and cup removal mechanism 2, a cup feeding mechanism 3, a main indexing turntable 5, an auxiliary indexing turntable 25, and a transmission mechanism 27. The main indexing turntable is equipped with ten stations in turn, namely, the cup feeding station 4, the stop station 6, the bottom feeding station 8, the preheating station 9, the bottom rolling station 10, the reheating station 13, the cup bottom station Knurling station 14, stop station 17, cup unloading station 12, stop station 26; the auxiliary indexing turntable is equipped with five stations in sequence, namely cup receiving station 23, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com