Hole bottom annular spacing strong suction device of through type down-the-hole hammer

A technology of annular space and suction device, which is applied to the driving device for drilling in the borehole, drilling equipment, earthwork drilling and mining, etc., and can solve the problem of loss of drilled ore samples when the diameter is reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

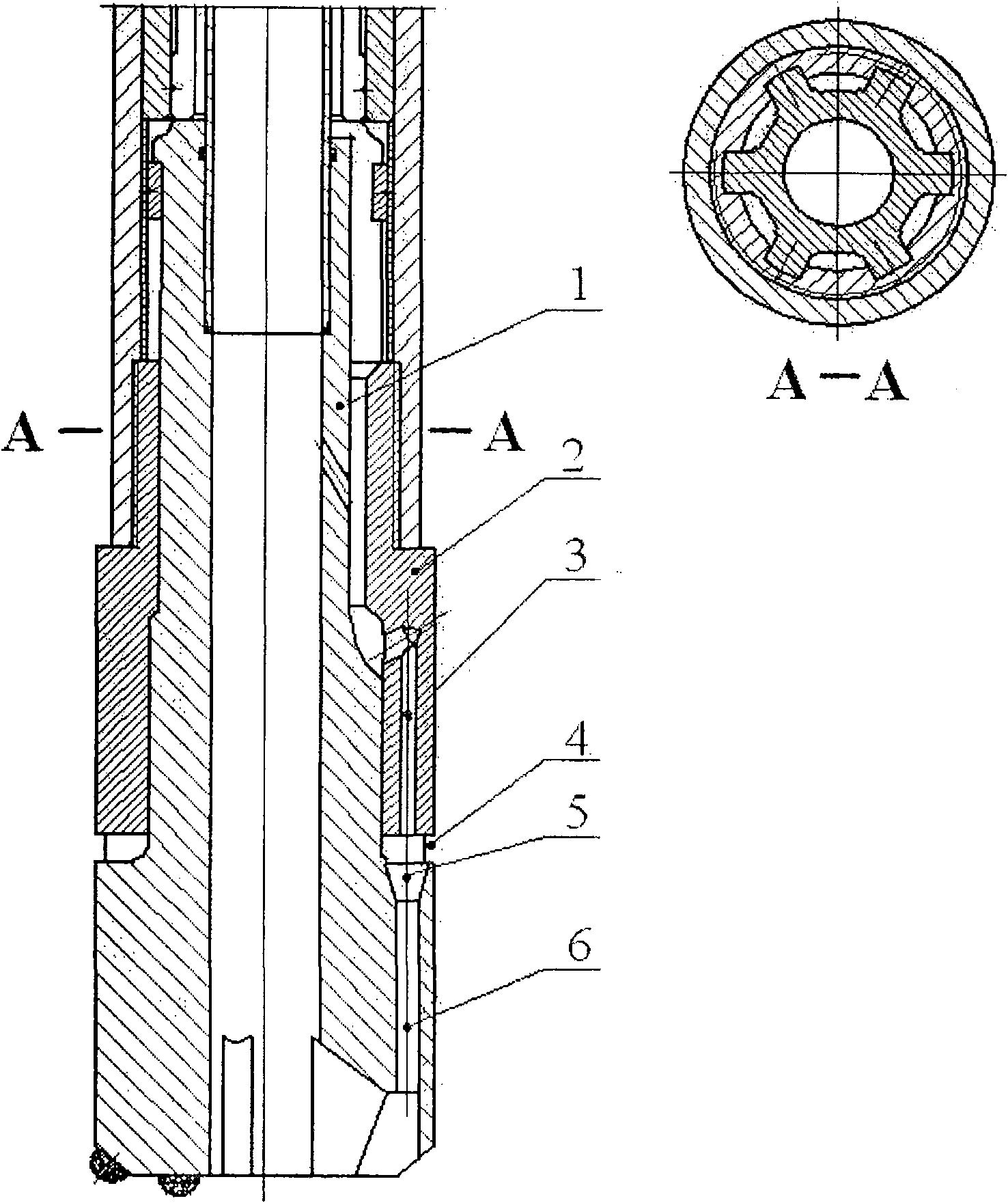

[0011] Below in conjunction with accompanying drawing and example the present invention is described in further detail:

[0012] The spline sleeve 2 is provided with a spline sleeve injection nozzle 3, the reverse circulation drill bit 1 is provided with a drill bit receiving chamber 5 and a drill bit mixing nozzle 6, and a reabsorption gap 4 is set between the spline sleeve 2 and the reverse circulation drill bit 1, and the spline The sleeve injection nozzle 3 communicates with the exhaust channel between the reverse circulation drill bit 1 and the spline sleeve 2, and the drill bit receiving chamber 5 communicates with the drill bit mixing nozzle 6.

[0013] During the normal impact drilling of the down-the-hole hammer, part of the exhaust gas after the impact of the driving piston enters the spline sleeve injection nozzle 3 through the exhaust channel between the reverse circulation drill bit 1 and the spline sleeve 2, and the high-speed gas is directly injected into the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com