Fully mechanized working faces along conveying end head hydraulic bracket

A technology of end hydraulic support and fully mechanized caving face, which is applied to mine roof support, mining equipment, earthwork drilling and mining, etc., and can solve the problem of frequent pulling of end support, little influence on normal production, and no need for roof bolt support. issues of protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

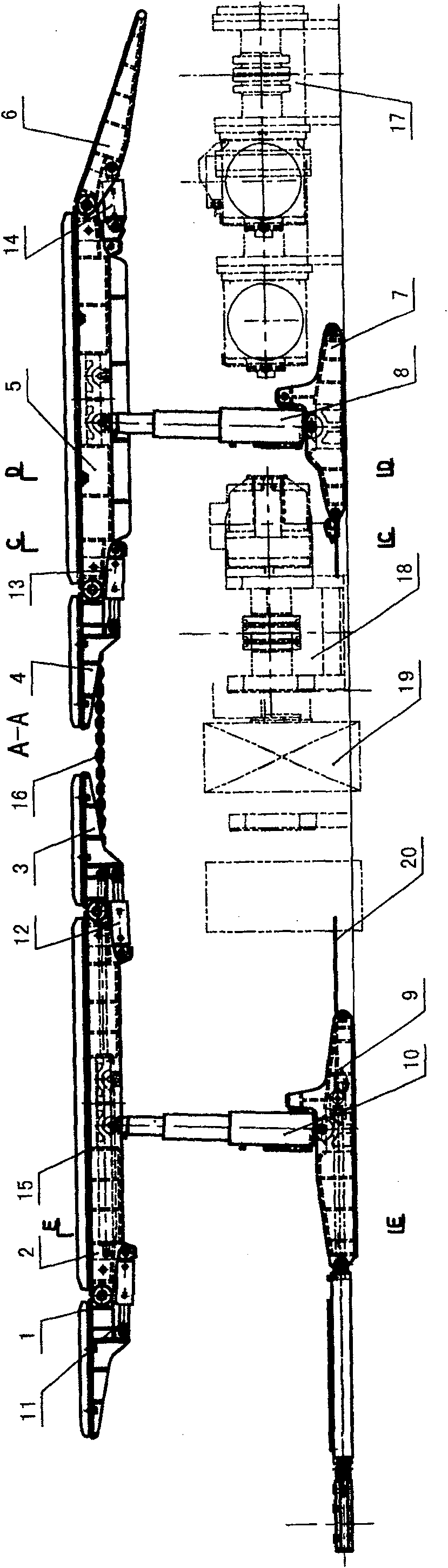

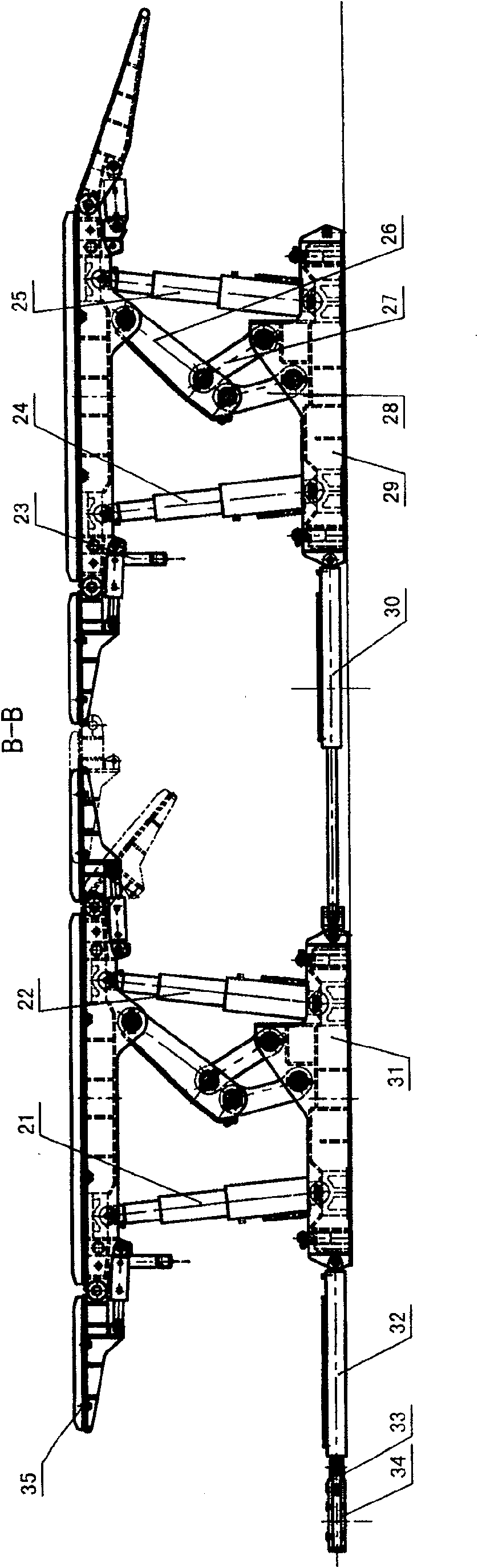

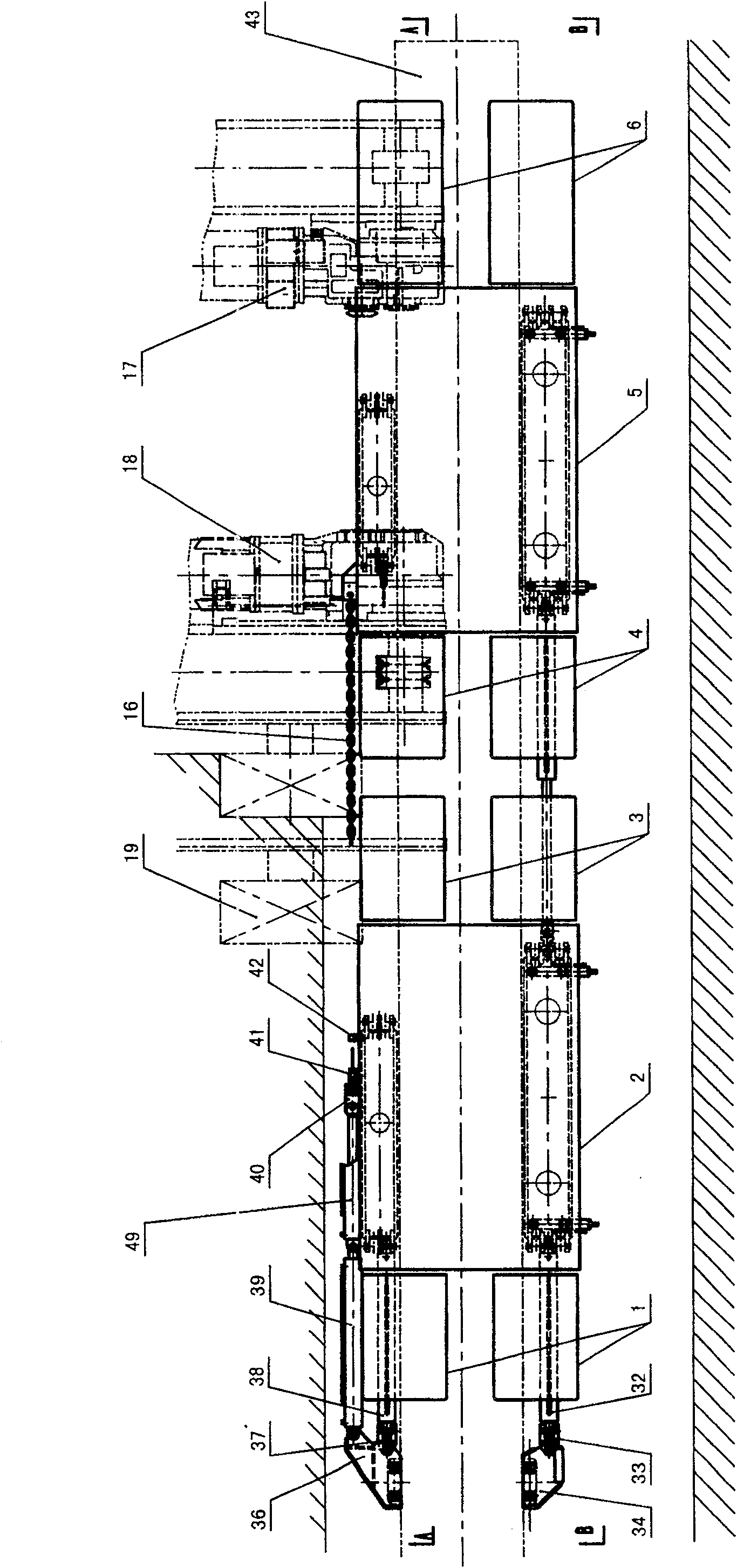

[0027] exist Figure 1~3 The structure of the hydraulic support at the Yunshun end of the fully mechanized caving face of the present invention shown in is as follows:

[0028] ① The hydraulic supports at the Yunshun end of the fully-mechanized caving face are two sets of front and rear. That is: a group consisting of front and rear frames, divided into front frame brackets and rear frame brackets. Both the front frame support and the rear frame support are composed of a top beam, three columns, two bases, hinged beams at the front and rear ends of the top beam, and a hydraulic control circuit.

[0029] ②The front frame bracket and the rear frame bracket are both left and right asymmetrical structures. That is to say, the structure of the working side of the front frame and the rear frame bracket and the sidewalk are asymmetric structures; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com