Method for cleaning air conditioner evaporator

A technology for evaporators and air conditioners, which is applied in the direction of cleaning heat transfer devices, lighting and heating equipment, etc. It can solve the problems of complex structure, decreased energy efficiency ratio, and increased power consumption, so as to prolong the service life, maintain the energy efficiency ratio, reduce the The effect of power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

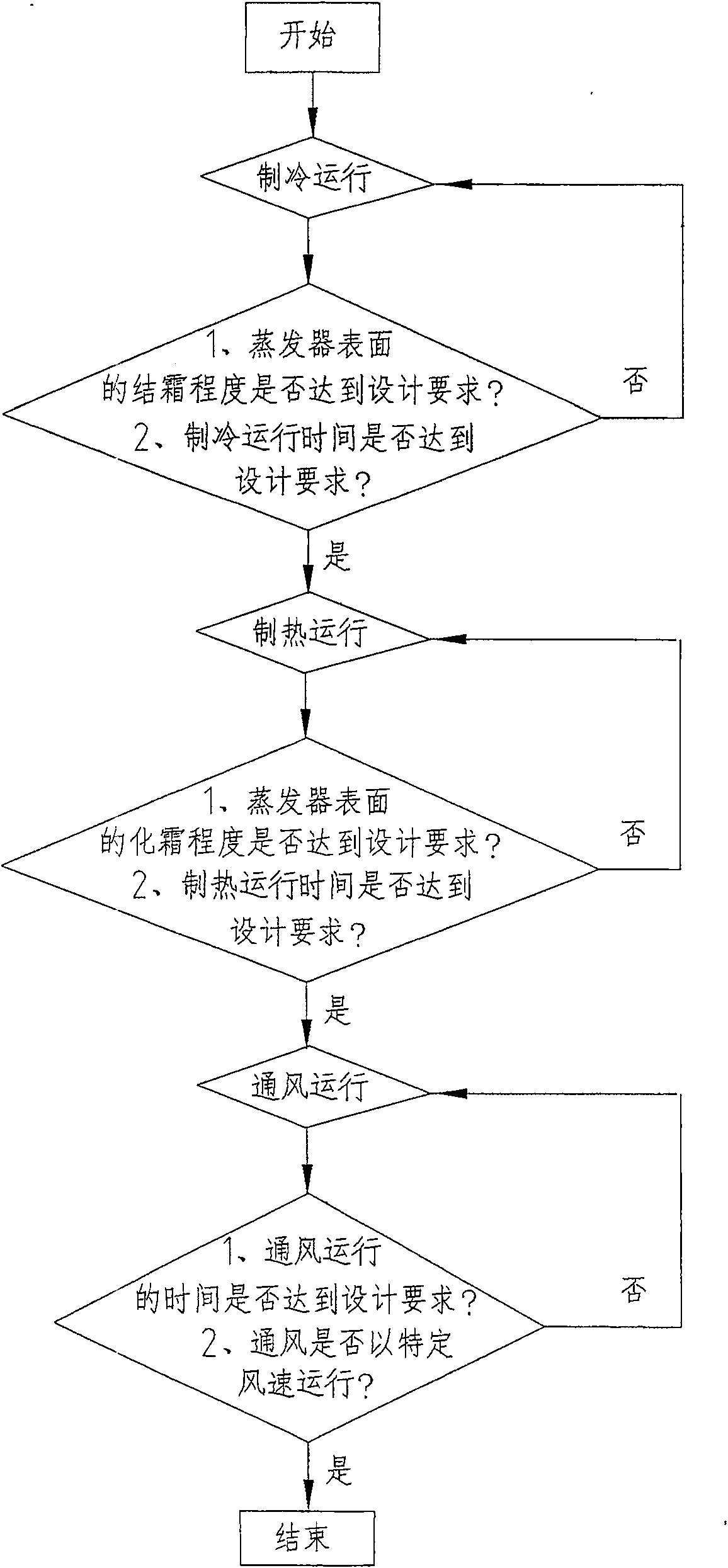

[0017] Such as figure 1 As indicated, the air conditioner starts to work and performs cooling operation;

[0018] During cooling operation, the controller of the air conditioner is generally a microprocessor. Through sensors such as thermistors, it will automatically and continuously detect whether the degree of frosting or icing on the surface of the evaporator reaches the pre-designed parameters, and at the same time, judge whether the cooling time meets the design requirements. parameter, if reached, the controller of the air conditioner executes the next step, and makes the air conditioner run in heating mode; otherwise, it continues in cooling mode.

[0019] During the heating operation, the controller of the air conditioner will also automatically and continuously detect whether the degree of defrosting or ice melting on the surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com