Scroller with axial gap control function

A technology of axial clearance and control function, which is applied in the direction of arc meshing engines, etc., and can solve problems such as mutual impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

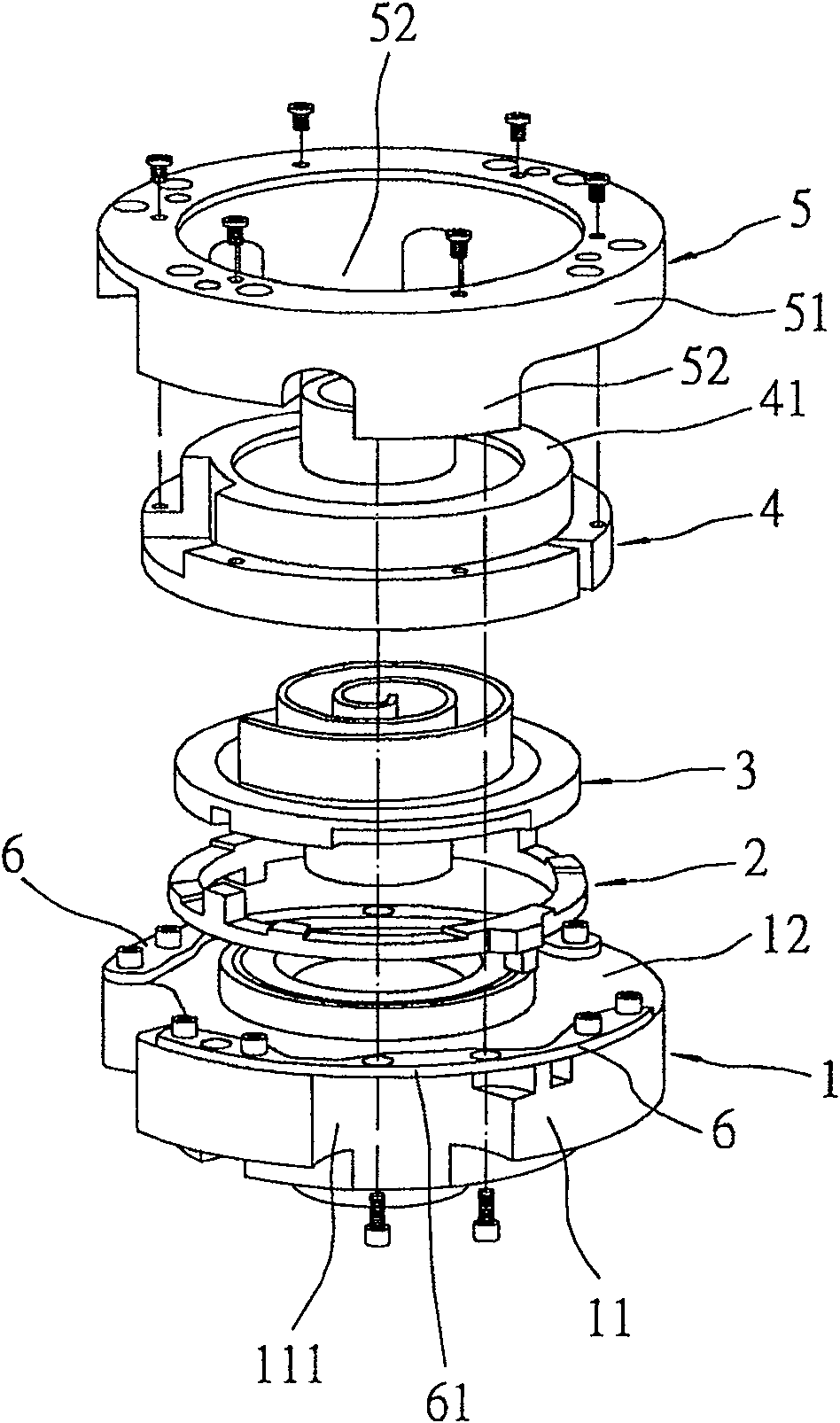

[0030] In order to further understand the features and technical content of the present invention, please refer to the following detailed description and accompanying drawings of the present invention.

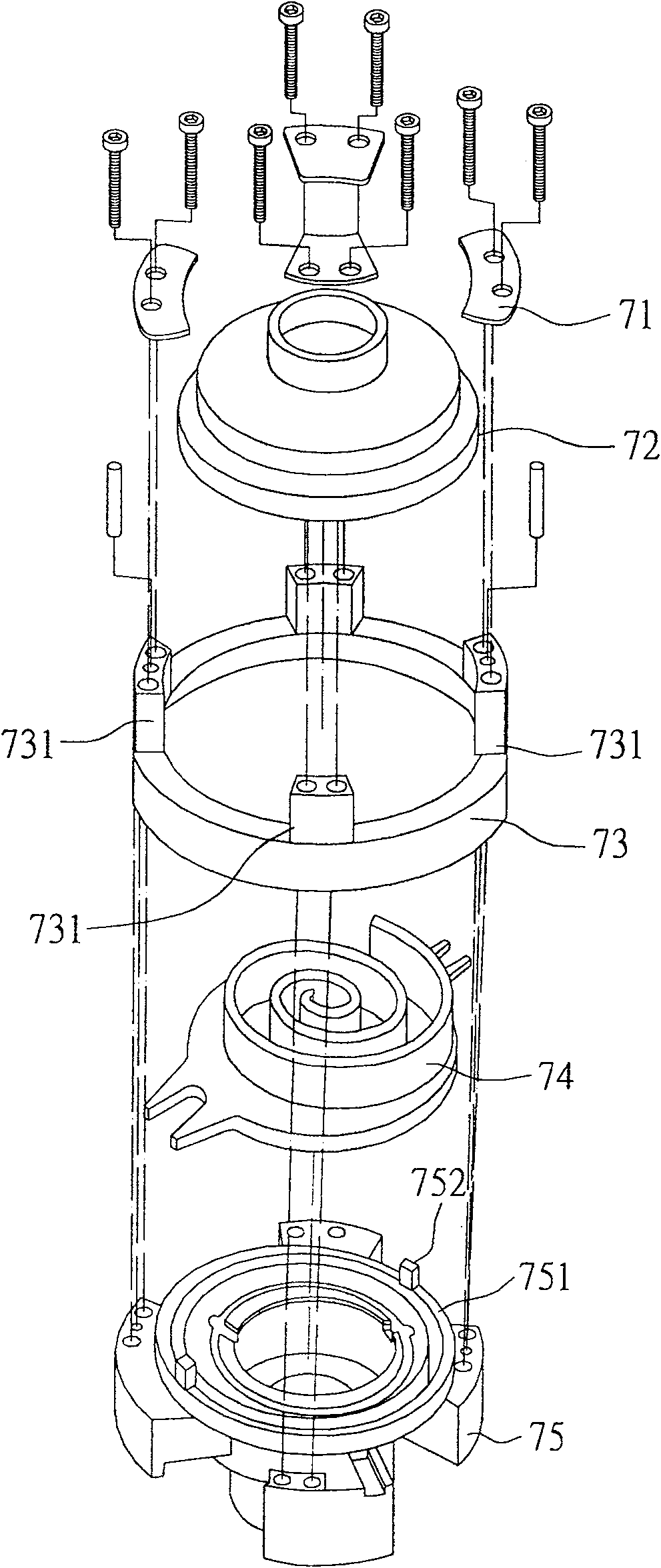

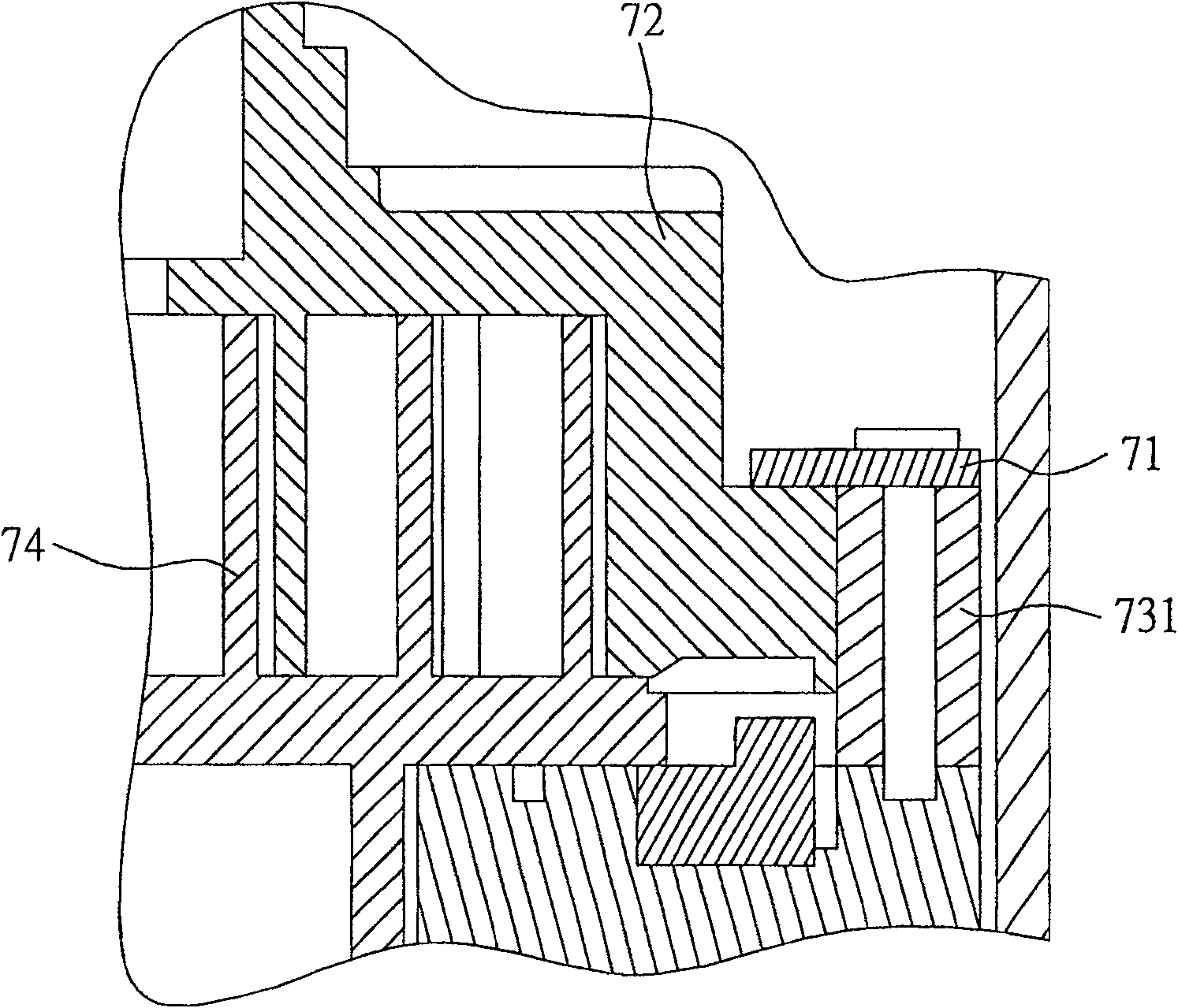

[0031] see image 3 As shown, the present invention provides a scroll device with an axial gap control function, which can provide the scroll device with a fixed gap control function when the scroll device is shut down, thereby reducing friction in the startup phase and noise during operation . The scroll device includes: an orbiting scroll 3, a fixed scroll 4, a positioning ring 5, a pair of flexible elements 6, and a skeleton arranged in the casing (not shown) of the scroll device 1.

[0032] The frame 1 is disposed in the casing (not shown) of the scroll device, and the peripheral edge 11 of the frame 1 has a pair of notches 111 .

[0033] The pair of flexible elements 6 may be in the form of metal beams, which are arranged on the top side 12 of the frame 1 along the edg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com