Horizontal dry-type magnetic sorting machine

A magnetic separator and dry technology, applied in the field of beneficiation machinery, can solve the problems of intensive feeding, inconvenience, and difficult to separate clearly, and achieve the effect of improving the selection rate and improving economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

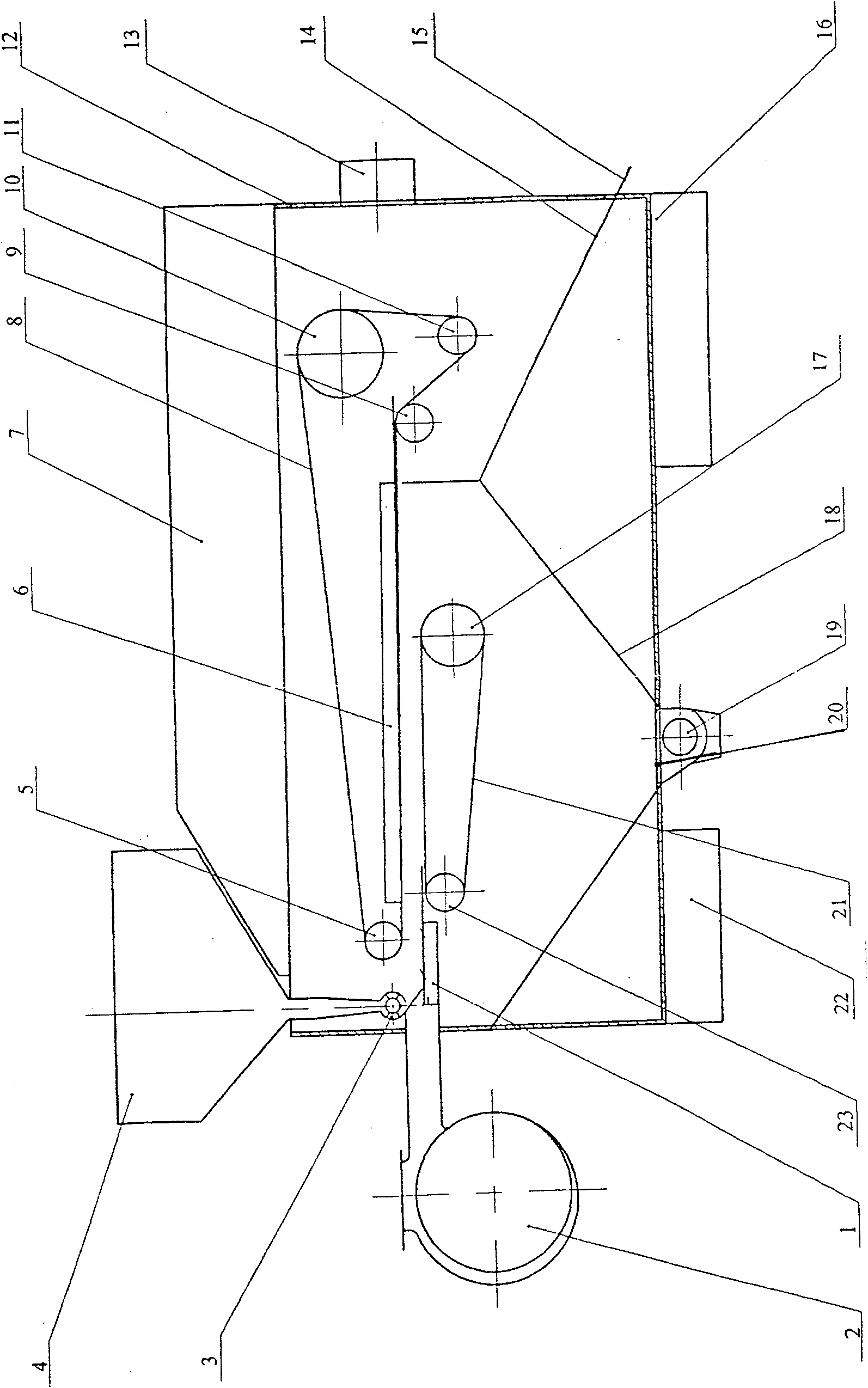

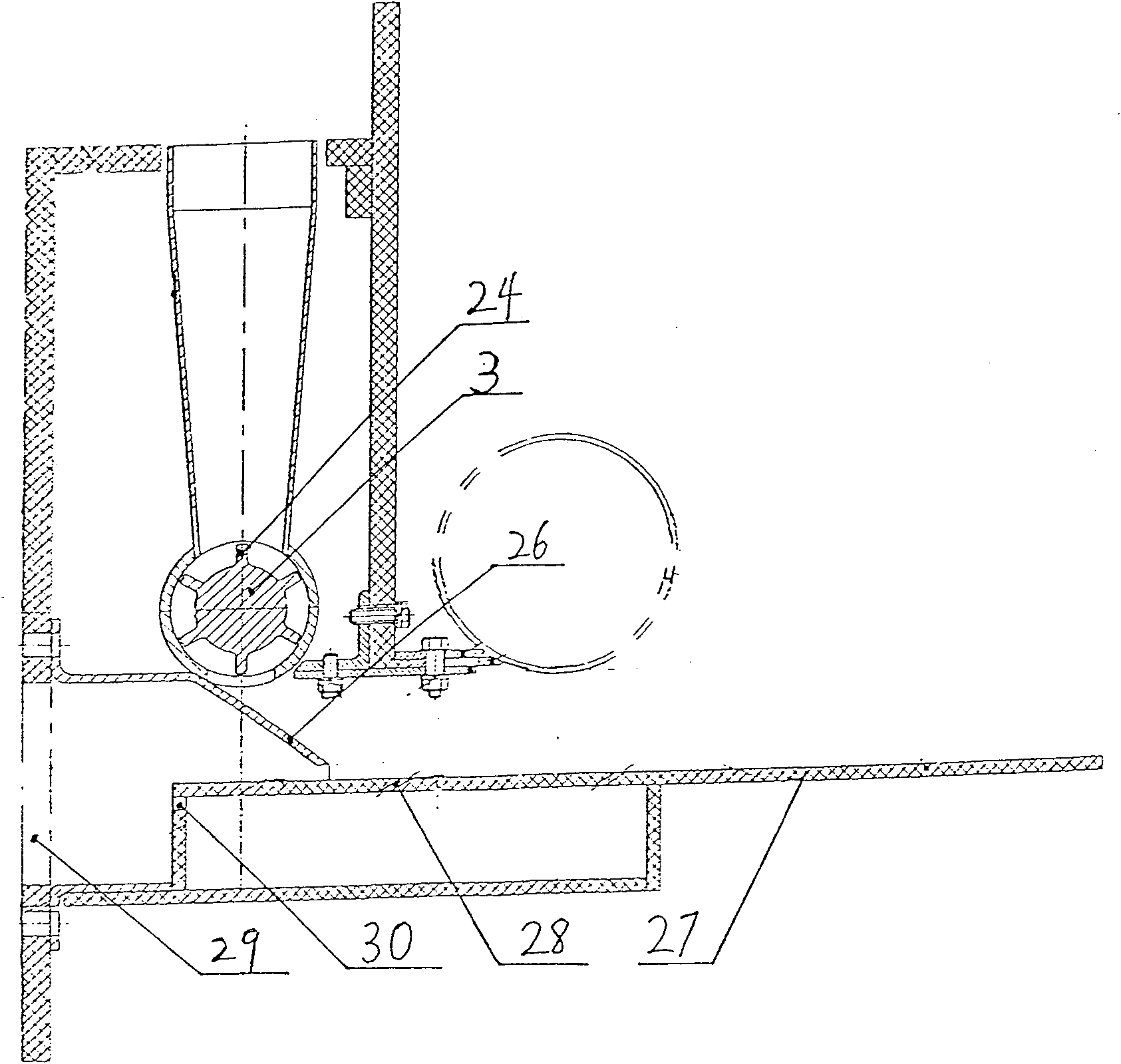

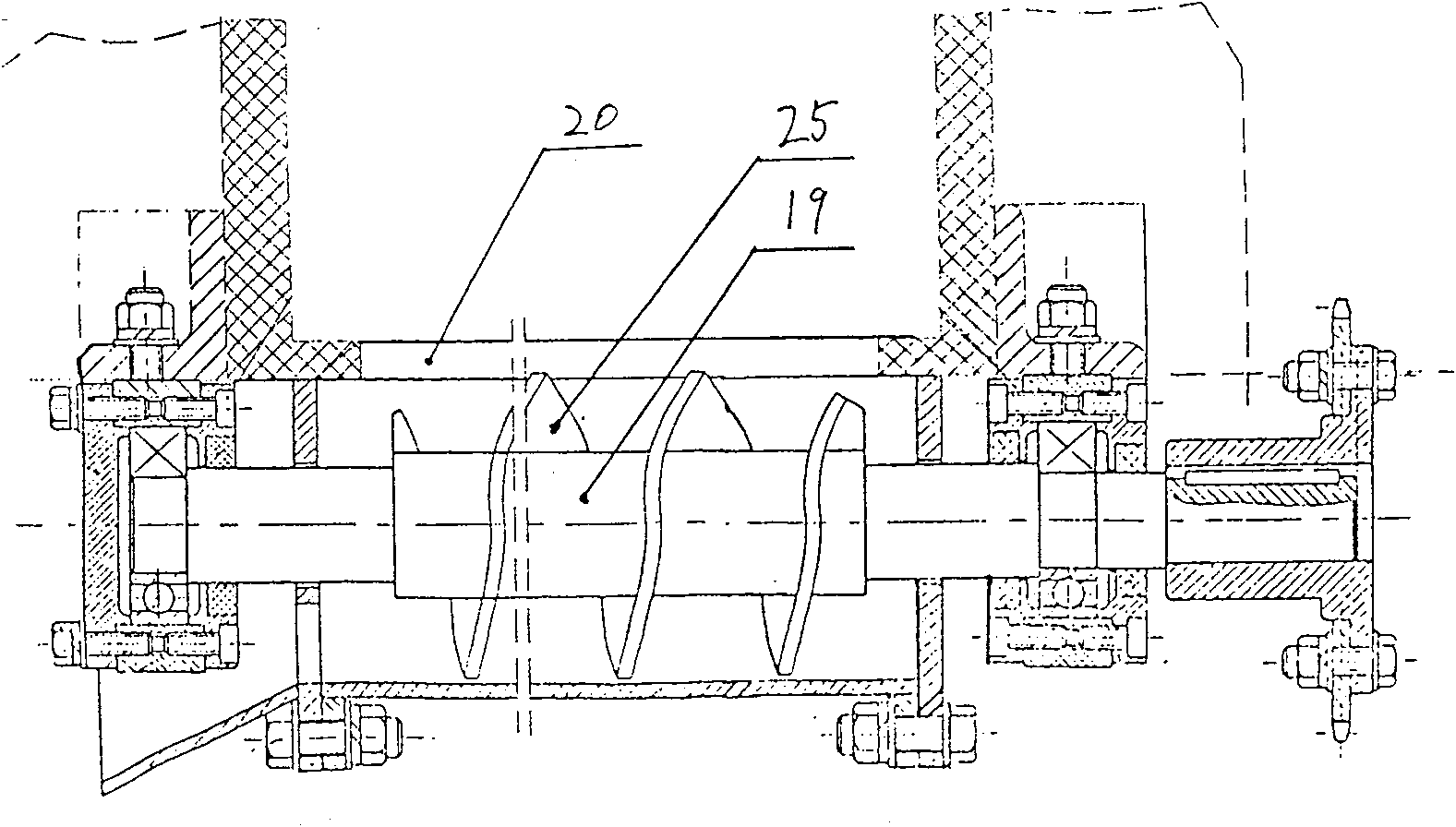

[0013] Such as figure 1 As shown, the horizontal dry magnetic separator includes a horizontal box-type case 12 and a cover 7, and the case is made of hard polyvinyl chloride plate welded to reduce the interference to the magnetic field and improve the magnetic separation effect. Place the hopper 4 above the cabinet and the slag discharge outlet 20 and the iron powder outlet 15 below the cabinet for placing the front base 22 and the rear base 16 of the cabinet. The cabinet is provided with a mineral material conveyor belt 21, and the mineral material conveyor belt 21 consists of The rubber roller 17 and the tension roller 23 are positioned, and move back and forth with the tension roller 23 to adjust the tightness. The iron powder conveyor belt 8 parallel to it is placed on the top of the mineral material conveyor belt 21, and there is a parallel distance between the two. The iron powder conveyor belt 8 is positioned by the belt roller 5, the pulley roller 9 and the rubber roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com