Method of multiple selecting iron from pyrite sintered slag

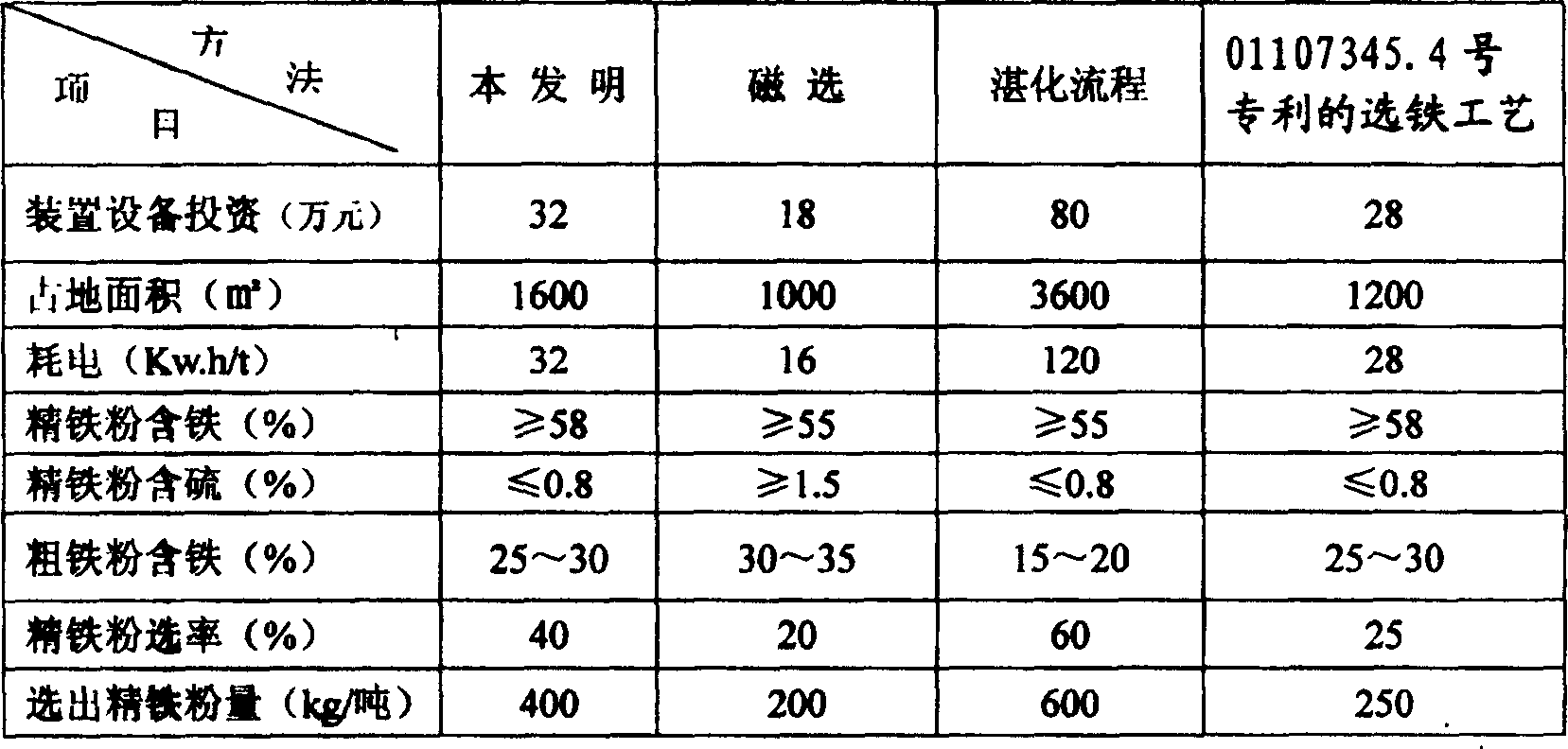

A technology for pyrite slag and iron selection, applied in chemical instruments and methods, wet separation, solid waste removal, etc., can solve problems such as high energy consumption, complicated operation and non-compliance, and achieve overall benefit improvement , The process is simple, the effect of improving the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

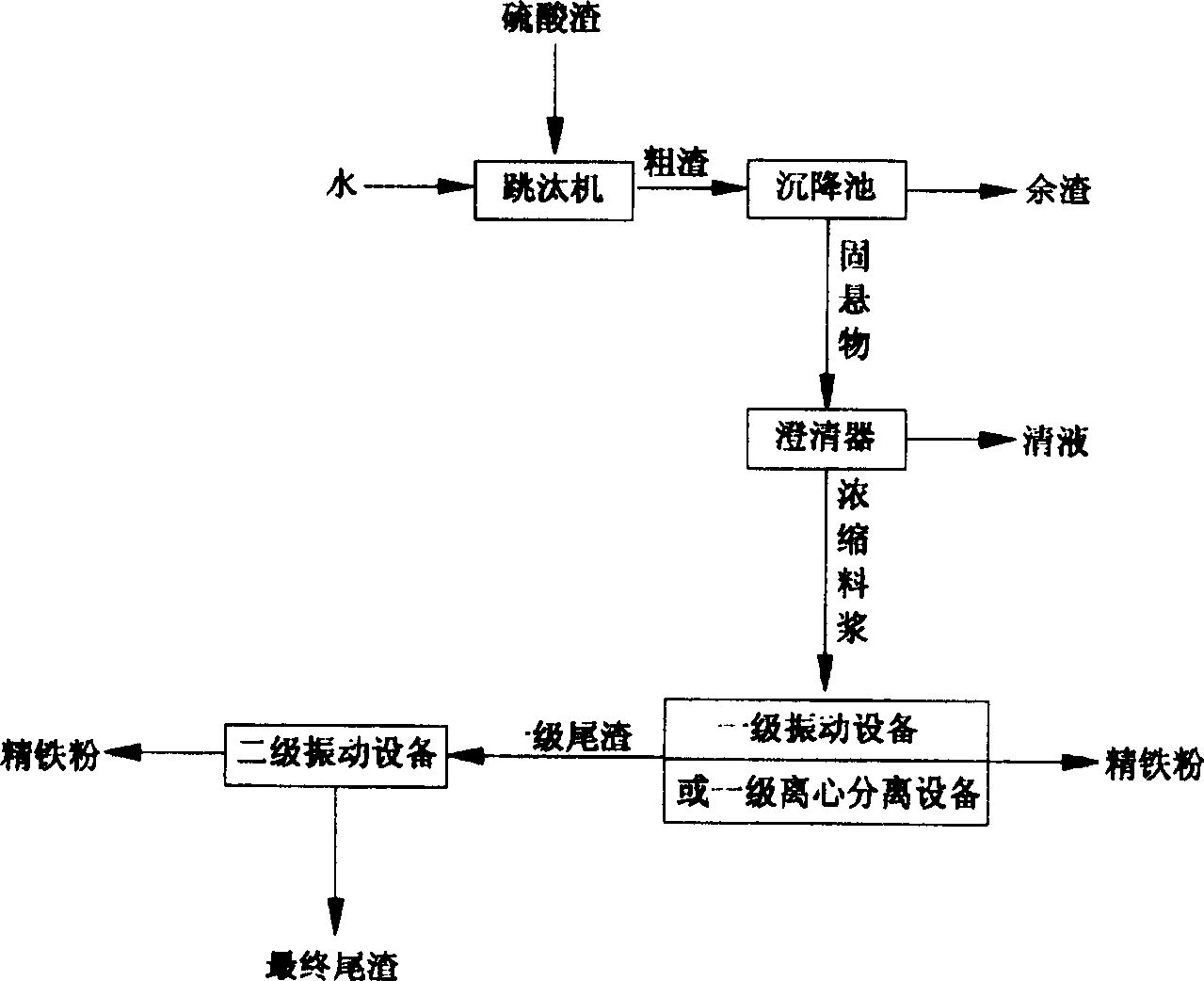

[0016] Example 1: The sulfuric acid slag roasted in the sulfuric acid fluidized furnace is directly or properly cooled and then sorted into fine iron powder and coarse slag by a tympanic jig in the state of water flow, and then the coarse slag is naturally settled in a settling tank , and then also include the slurry concentration and fine iron powder sorting steps in turn:

[0017] a. Slurry concentration: Send the remaining solid suspended matter solution after settlement into the clarifier for clarification for 2.5 to 4 hours, and then discharge the clear liquid to obtain a concentrated slurry with a pulp weight concentration of 20 to 30%;

[0018] b. Separation of refined iron powder: The separation of the above-mentioned concentrated slurry is to use a two-stage shaker for vibration separation. First, the concentrated slurry is sent to a first-stage shaker for vibration separation, and the iron content weight is 55-60. % refined iron powder and first-level tailings, and t...

Embodiment 2

[0019] Embodiment 2: The sulfuric acid slag roasted in the sulfuric acid fluidized furnace is directly or properly cooled and sorted into refined iron powder and coarse slag through a jig machine in a water-through state, and then the coarse slag is naturally settled in a settling tank, and then It also includes the steps of thickening the slurry and sorting fine iron powder in turn:

[0020] a. Slurry concentration: Send the remaining ore-containing solution after settlement into the clarifier for clarification for 2.5-4 hours, and then discharge the clear liquid to obtain a concentrated slurry with a weight concentration of 20-30% of the pulp;

[0021] b. Separation of fine iron powder: the selection of the concentrated slurry is to adopt the first-level centrifugal separation and the second-level vibration separation, that is, the concentrated slurry is first sent to the first-level centrifugal separator for centrifugal separation, and the iron-containing weight is 55 ~60% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com