Reinforced transposable transferring device of automatic toothed joggler

A technology of conveying device and joiner, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc. It can solve problems such as easy sticking of bristles by glue, poor effect of wood finger joints, and timely correction by hand, so as to achieve transposition The effect of stability, simple structure and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

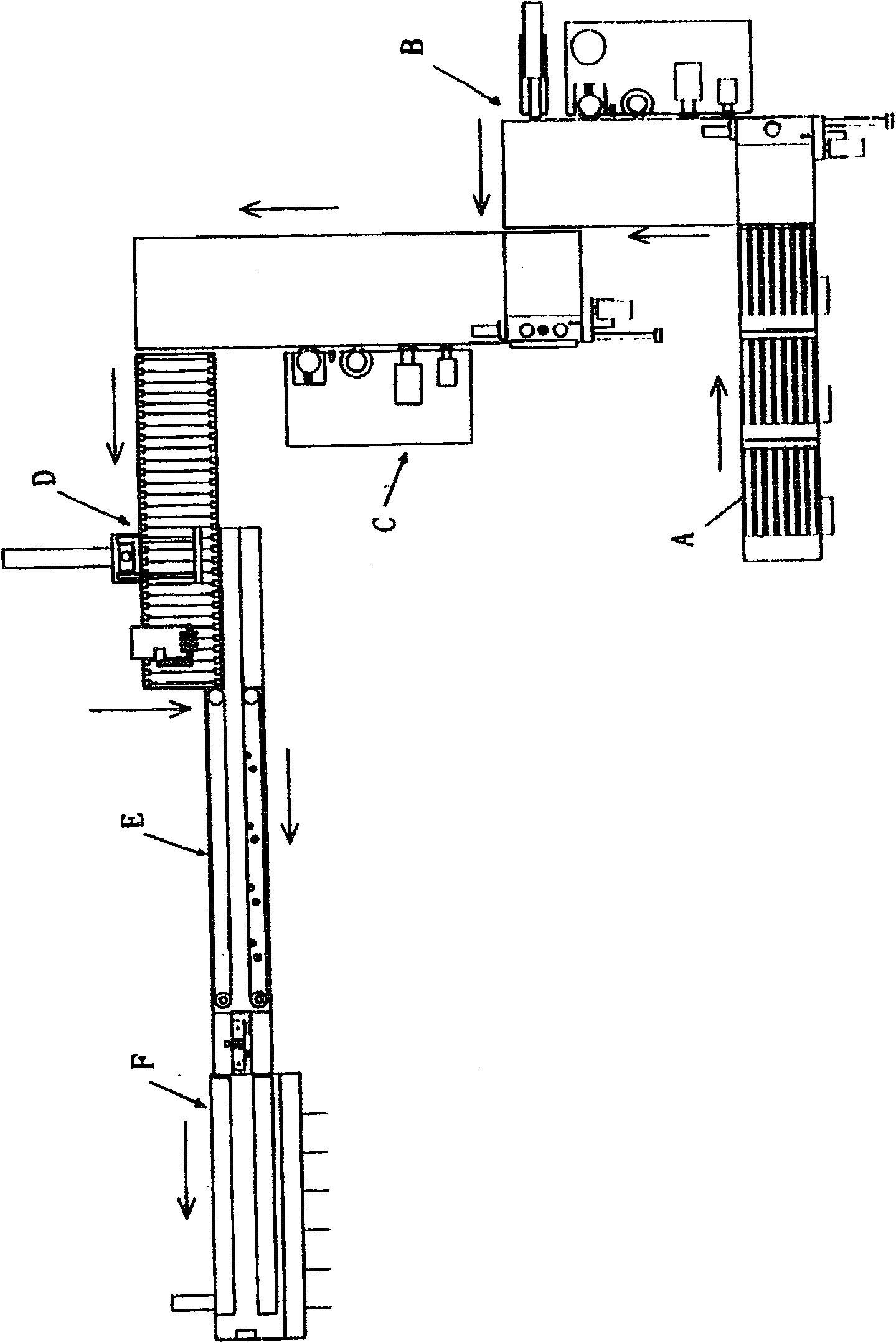

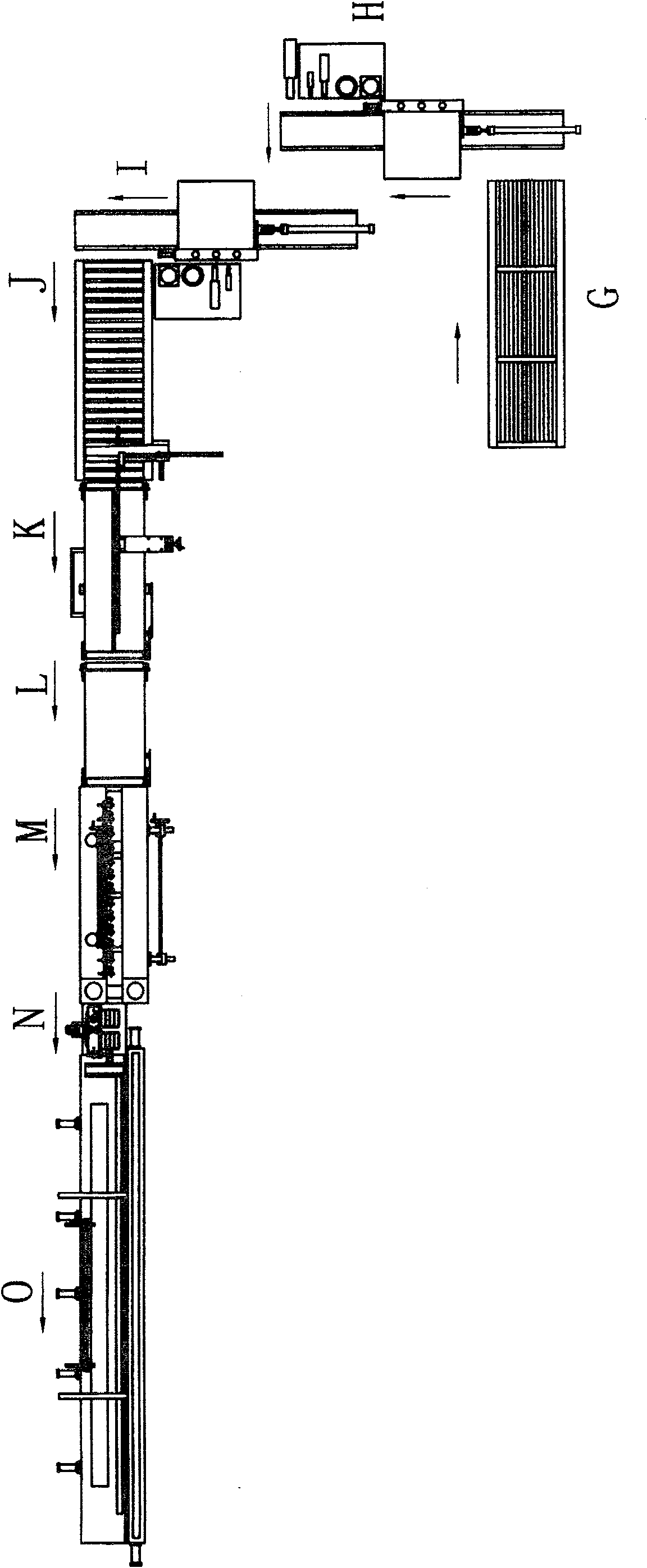

[0024] Such as image 3 Shown, material storage device G is used for storing timber 14, is located at the timber comb milling machine H of material storage device one side, is provided with automatic gluing device I on the timber comb milling machine, and the timber that is coated with glue is transported to The wood is stored on the conveyor J for the wood, the post-forced indexing conveying mechanism K receives the conveying signal, and the wood is reversed and sent to the stable guiding conveying mechanism L, the guiding pretensioning mechanism M, the conveying pretensioning mechanism N, and the adjustable butt joint Machine 0 to complete the entire safety production line for short material extension.

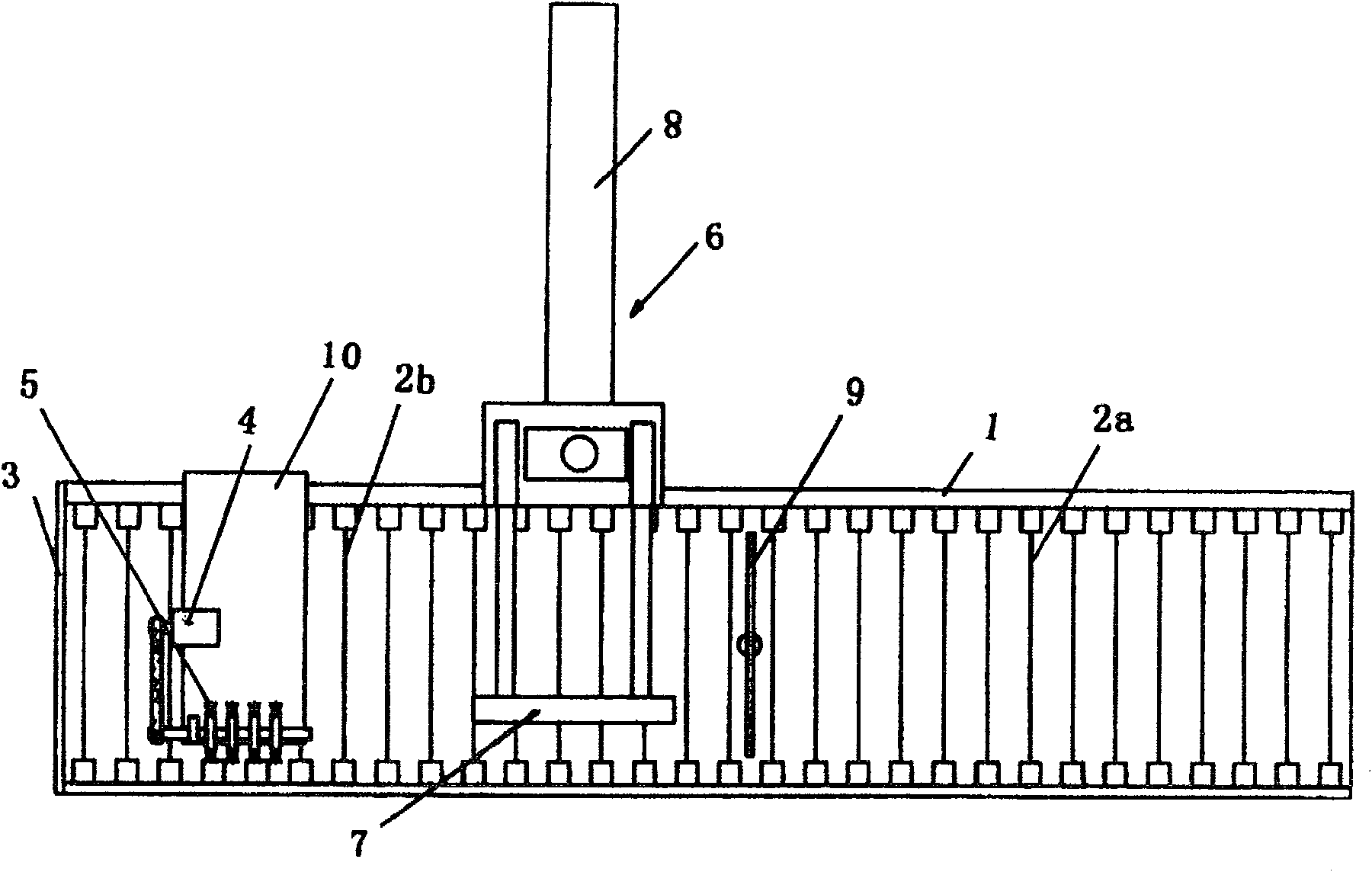

[0025] Such as Figure 4 , 5 As shown, the forced indexing conveying device of the automatic tooth tenon joiner includes a stand 11, a conveyor belt 12, a roller 13, and a motor driving the roller 13. The conveyor belt 12 is arranged on the roller 13, and the roller 13 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com