Cu-Cr-Zr alloy preparation technology for contact wire

A preparation process and contact wire technology, applied in the field of Cu-Cr-Zr alloy preparation process for contact wire, can solve the problems of excessive content range of alloy elements, difficult performance control, low electrical conductivity, etc., and achieve simplified process and equipment and Ingredient system, low cost, enhanced effect of heat treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

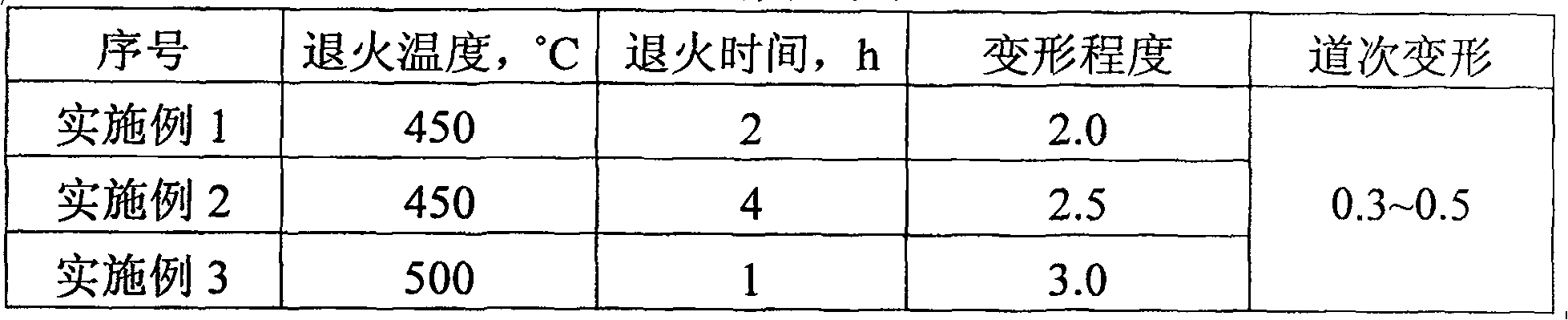

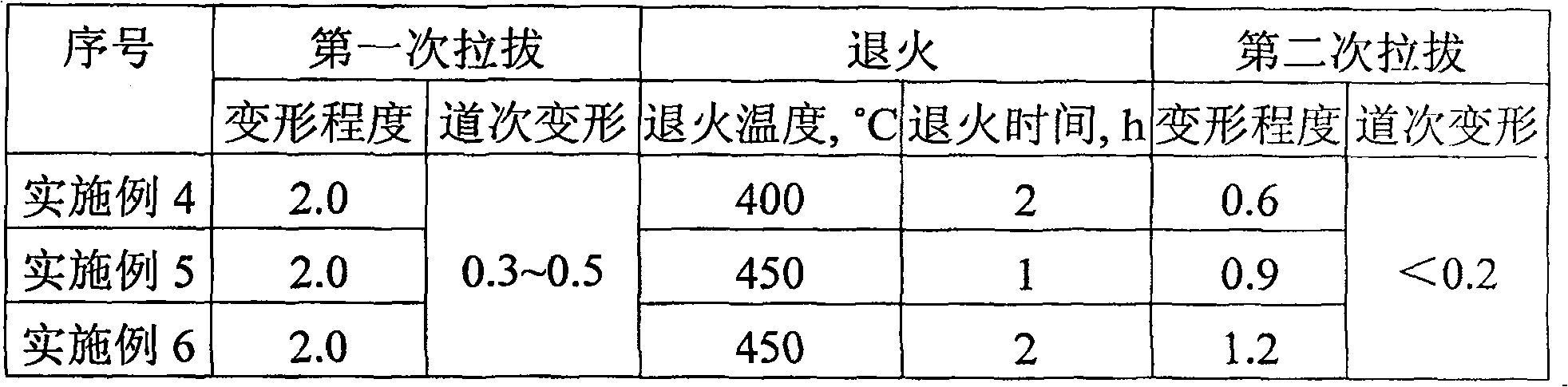

[0024] Following is the unified description of embodiment 1~6:

[0025] Melt and cast Cu-Cr, Cu-Zr and Cu-Si master alloy ingots in a vacuum induction furnace, the components are Cu-(4~10)%Cr, Cu-(12~20)%Zr and Cu-( 15-20)% Si.

[0026] The electrolytic Cu, Cu-Cr, Cu-Zr, and Cu-Si master alloys are prepared according to the mass percentage of the alloy components, wherein the Cr content is (0.30-0.50)%, the Zr content is (0.10-0.15)%, and the Si content is (0.01~0.02)%, the rest is Cu.

[0027] First place the electrolytic Cu in a vacuum induction furnace, melt it under the atmospheric pressure of 0.01-0.1Pa, let it stand at 1250°C for degassing, then fill the furnace with Ar to 30kPa, add Cu-Cr master alloy, and then add Cu- Zr and Cu-Si master alloy, electromagnetically stir evenly and let stand for 5-15min.

[0028] Water-cooled copper molds are used to cast ingots at 1200°C, the solidification rate is controlled to be ≥3°C / s, and the cooling rate after solidification is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com