Equipment for bending, forming and tempering automobile glass

A bending forming and automotive glass technology, which is applied in glass forming, glass reshaping, glass manufacturing equipment, etc., can solve the problems of curvature uniformity and poor optical performance, and achieve curvature uniformity, weight reduction, and cumulative error reduction small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

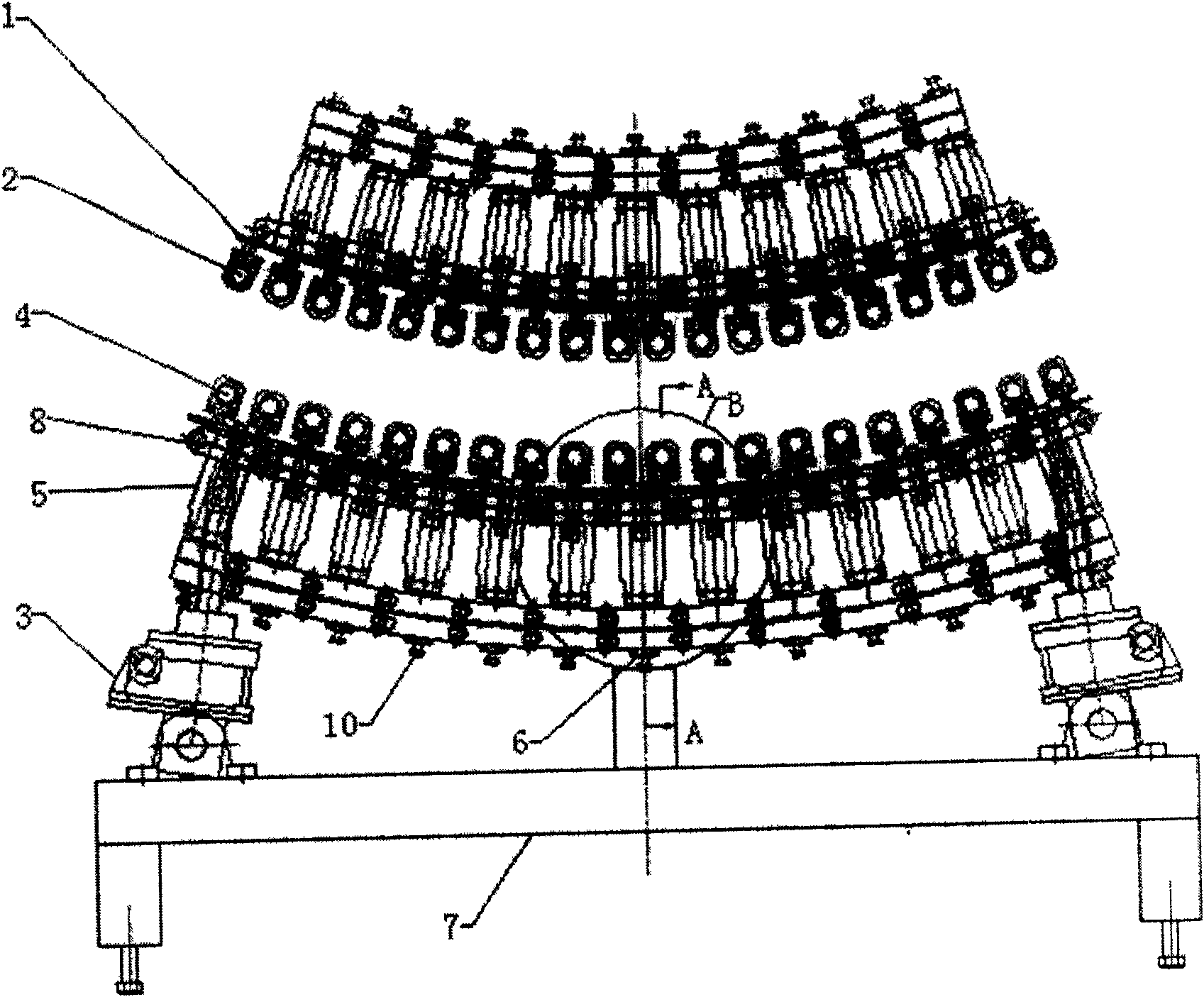

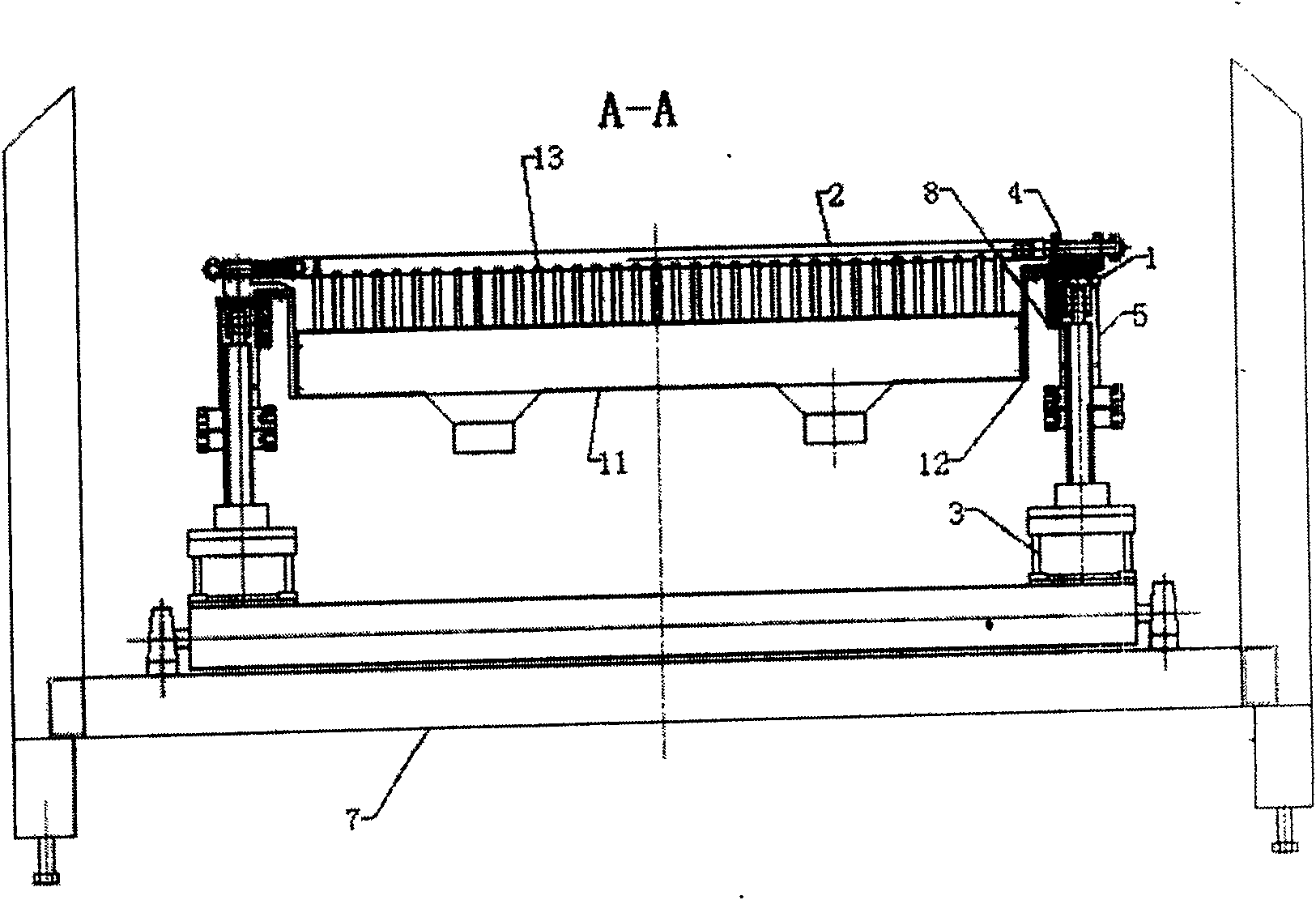

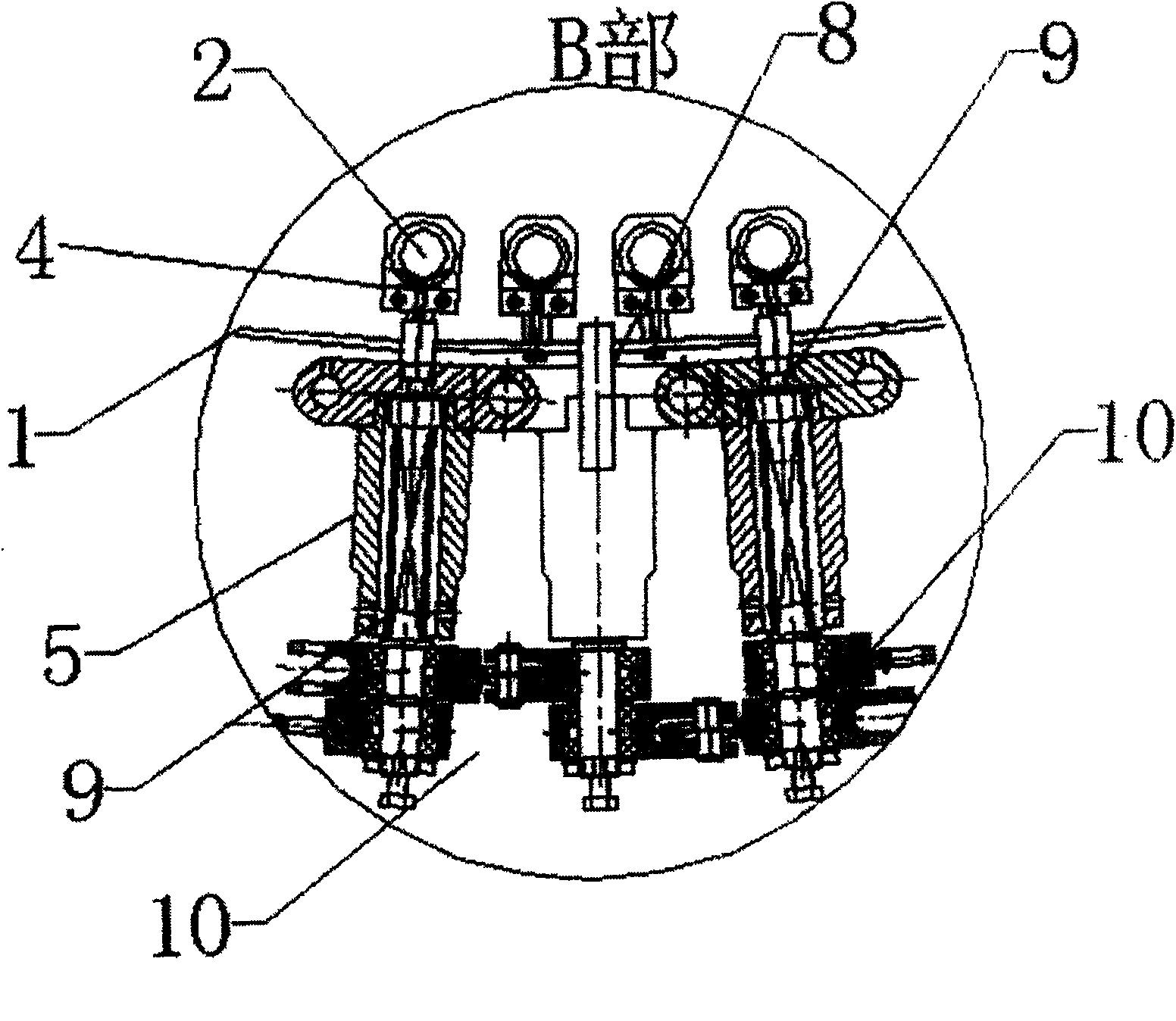

[0013] The structure of the present invention includes a supporting mechanism, a bending mechanism, a transmission mechanism and an air grid mechanism. The bending mechanism includes two sets of bending mechanisms and rollers 2 corresponding up and down. The upper and lower bending mechanisms respectively include bending mechanisms on both sides, and each side bending mechanism consists The spring steel plate 1, the joint frame, the lifter 3, and the bearing seat 4 are composed of two ends of the spring steel plate 1 and the lifter 3. The spring steel plate 1 is hinged with the joint frame. There is a fixed joint in the middle of the bottom edge of the joint frame. The bearing housing 4 is installed on the spring steel plate 1, and the upper and lower bending mechanisms are mutually inverted. The upper and lower rows of rollers have a convex and concave curvature, and the upper and lower rows of rollers maintain the corresponding spacing of the thickness of the glass plate.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com