Prestressed concrete hollow square pile and its forming mould

A hollow square pile and forming mold technology, applied in ceramic forming machines, sheet pile walls, manufacturing tools, etc., can solve the problems of low folding and assembly efficiency of hanging bolts, increase user cost, and damage to hanging bolts. The protective layer is uniform, the folding efficiency is high, and the service life is long.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

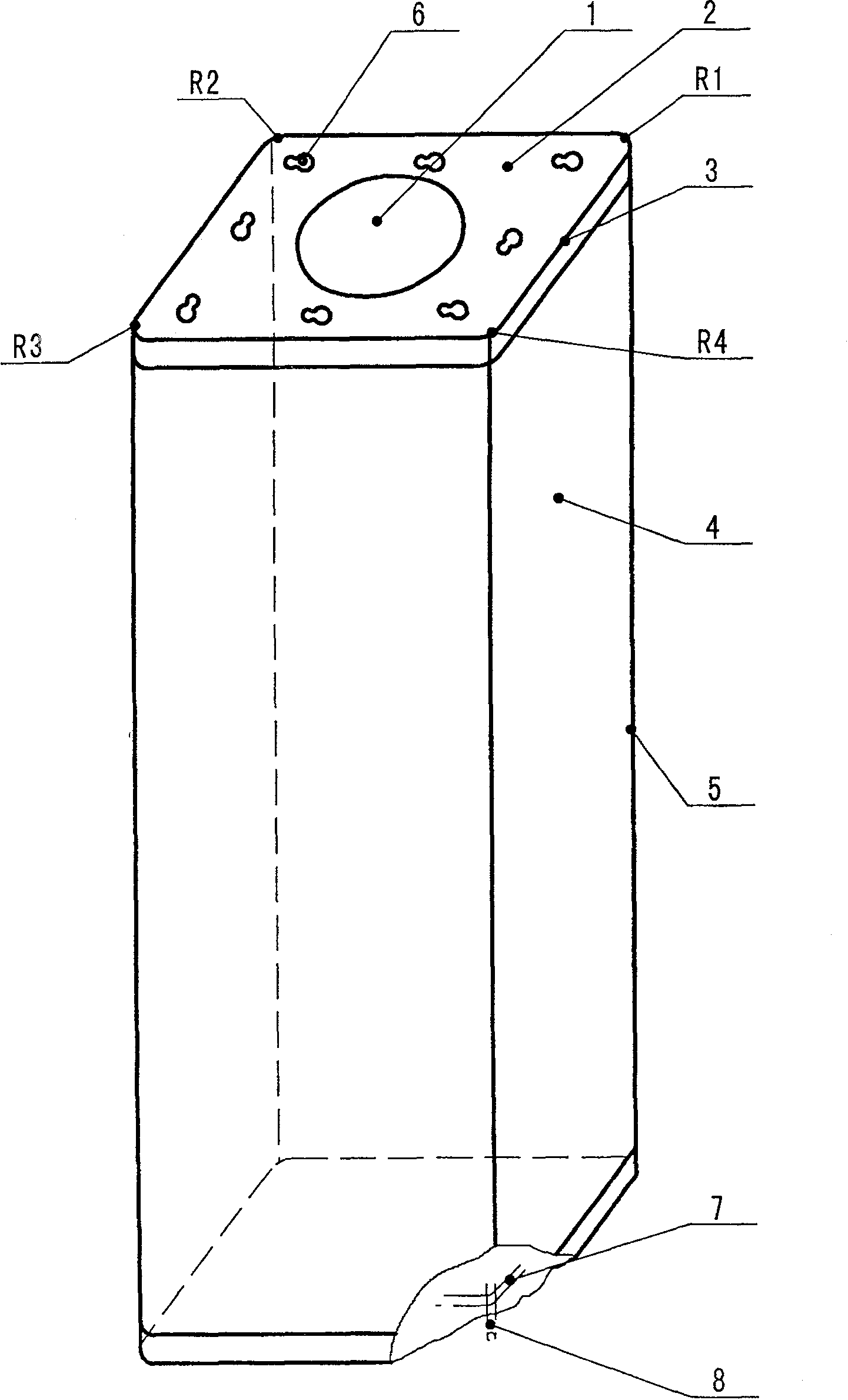

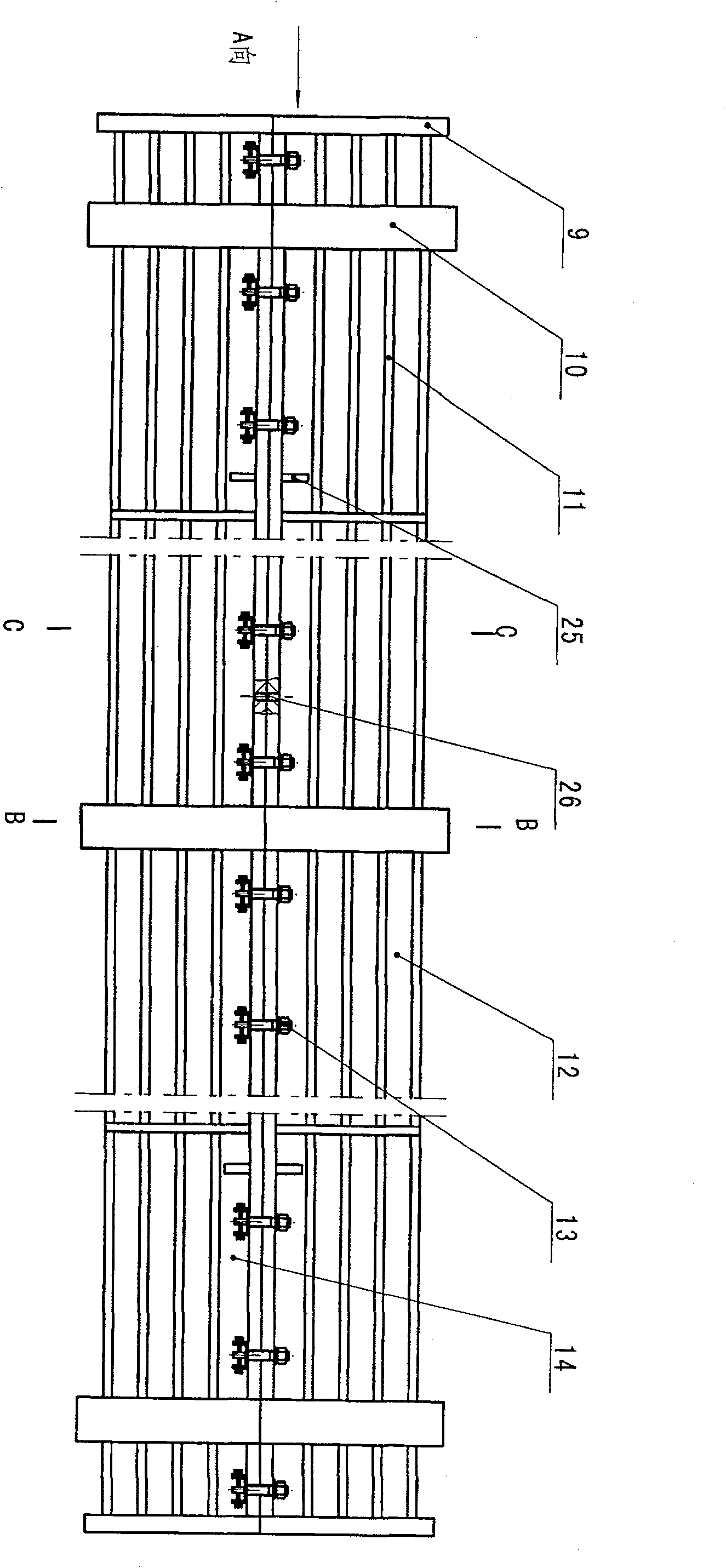

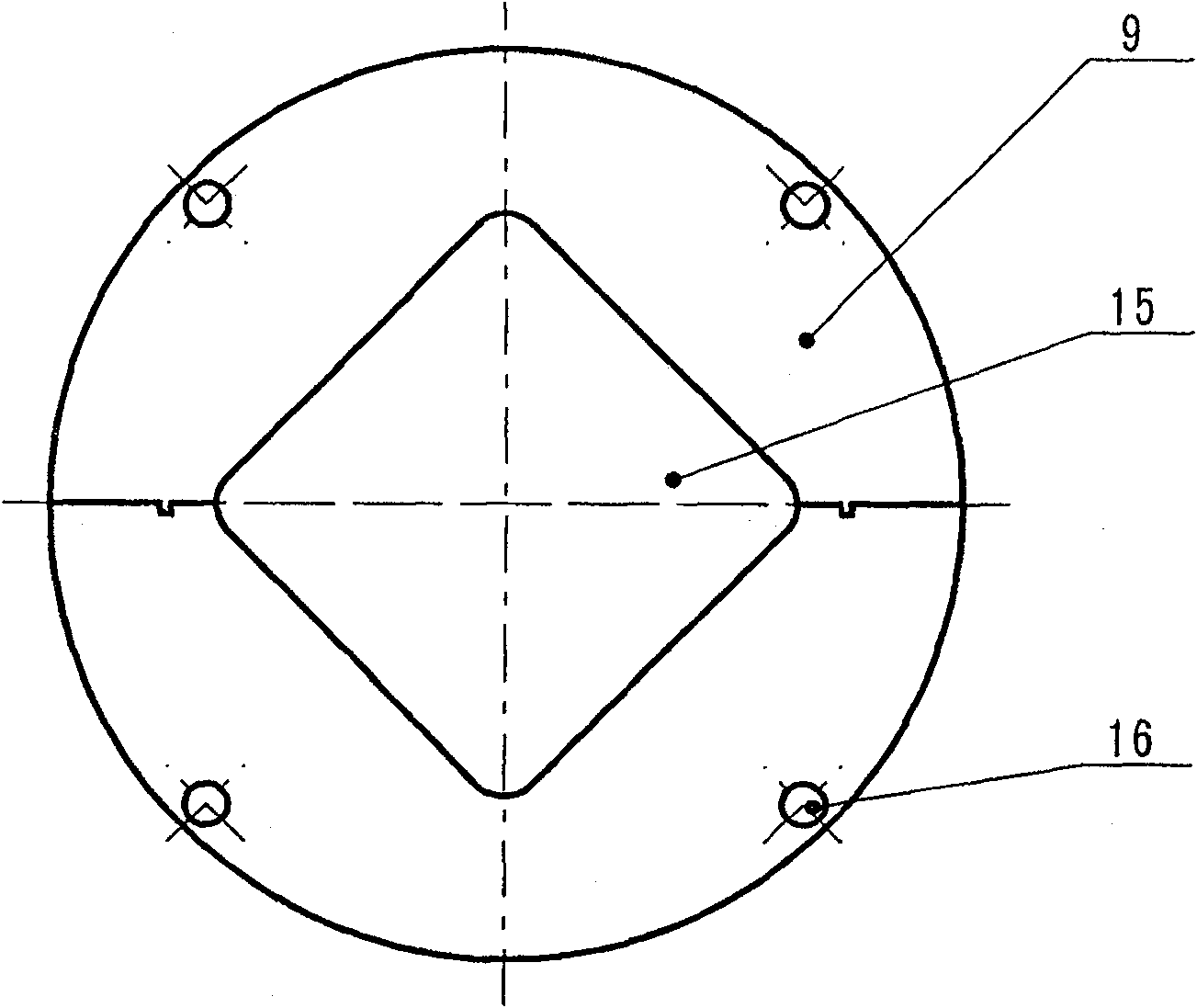

[0022] figure 1 Among them, the prestressed concrete hollow square pile includes a square pile body 4 and a square metal end plate 2. The square pile body 4 contains a steel cage and concrete. The plate 2 is arranged on the two ends of the square pile body 4, corresponding to the central round hole 1 on the square pile body 4, the square metal end plate 2 is also provided with the central round hole 1, and the periphery 3 of the square metal end plate 2 is provided with There are welding grooves, and the square metal end plate 2 is symmetrically provided with anchor holes 6; the reinforcement cage includes the main reinforcement 8 and the stirrup 7, and the stirrup 7 is welded on the main reinforcement 8 in a spiral shape; the square pile body 4 and the square metal end plate The radius R of the four arc corner sides 5 of 2 1 , R 2 , R 3 , R 4 Equal, for a 300mm×300mm prestressed concrete hollow square pile, R 1 =R 2 =R 3 =R 4 =15mm, for prestressed concrete hollow squ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com