Polyvinyl alcohol film preparation method

A polyvinyl alcohol-based and polyvinyl alcohol technology, which is applied in the field of preparation of polyvinyl alcohol-based films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The invention provides a method for preparing a polyvinyl alcohol-based film, comprising: providing a composite film; the composite film includes a first polyvinyl alcohol-based film layer and a second polyvinyl alcohol-based film layer arranged on the first polyvinyl alcohol-based film layer Polyvinyl alcohol-based film layer; the first polyvinyl alcohol-based film layer is a polarizer manufacturing layer; the second polyvinyl alcohol-based film layer is a water-soluble polyvinyl alcohol-based film; the composite film is swollen and dyed , After stretching and fixing, the water-soluble polyvinyl alcohol-based film is removed to obtain a polyvinyl alcohol-based film.

[0025] The present invention has no special limitation on the sources of all raw materials, which can be commercially available.

[0026] According to the present invention, the composite film includes a first polyvinyl alcohol-based film layer and a second polyvinyl alcohol-based film layer arranged on t...

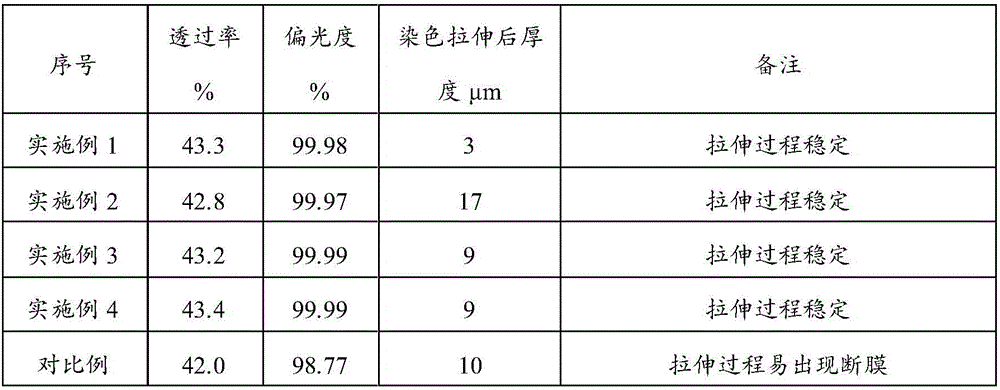

Embodiment 1

[0058] The film coating solution for the second polyvinyl alcohol film layer is configured according to the mass ratio, polyvinyl alcohol: glycerol: sodium lauryl sulfate: water = 8: 0.64: 0.08: 92. The degree of polymerization of polyvinyl alcohol is 2800, and the degree of saponification is 89%.

[0059] The film coating solution for the first polyvinyl alcohol film layer is configured according to the mass ratio, polyvinyl alcohol: glycerol: sodium lauryl sulfate: water = 8: 0.64: 0.08: 92. Wherein the degree of polymerization of polyvinyl alcohol is 9000, and the degree of saponification is 99.99%.

[0060] Through double-layer co-extrusion, it is coated on a drum or a steel belt, and dried and formed on its surface. Usually, the drying temperature is preferably 70°C; the moisture content is controlled to 17%, and a preformed film is obtained. The pre-formed film can be dried by multi-roller and oven to further control the film to 3.5%. After drying, the manufacture ...

Embodiment 2

[0063] The film coating solution for the second polyvinyl alcohol film layer is configured according to the mass ratio, polyvinyl alcohol: glycerol: sodium lauryl sulfate: water = 40: 12: 0.4: 48. Wherein the degree of polymerization of polyvinyl alcohol is 1000, and the degree of saponification is 87%.

[0064] The film coating solution of the first polyvinyl alcohol film layer is configured according to mass ratio, polyvinyl alcohol: glycerol: sodium lauryl sulfate: water = 40: 12: 0.4: 48. Wherein the degree of polymerization of polyvinyl alcohol is 1000, and the degree of saponification is 99.99%.

[0065]Through double-layer co-extrusion, it is coated on a drum or a steel belt, and dried and formed on its surface. Usually, the drying temperature is preferably 99°C; the moisture content is controlled to 25%, and a preformed film is obtained. The pre-formed film can be dried by multi-roller and oven to further control the film to 3.5%. After drying, the manufacture of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com