Prestressed concrete hollow square pile and formation die

A technology of hollow square piles and forming molds, which is applied in the direction of molds, sheet pile walls, buildings, etc., can solve the problems of poor sealing of tongue and groove boards, easy occurrence of slurry leakage, product scrapping, etc., achieve beautiful pile body, prolong service life, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The prestressed concrete hollow square pile and the forming mold structure of the present invention are described in conjunction with the accompanying drawings and embodiments.

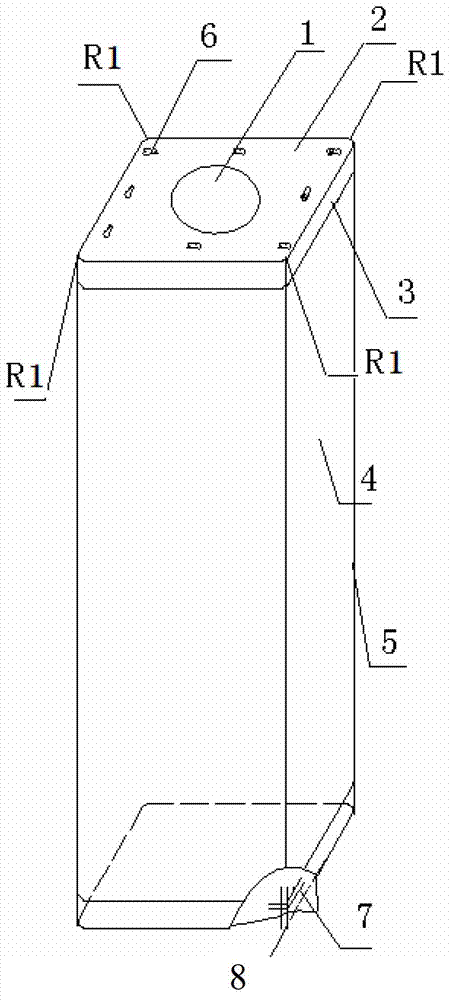

[0028] like figure 1 As shown, the prestressed concrete hollow square pile includes a square pile body 4 and a square metal end plate 2. The square pile body 4 contains a steel cage and concrete. The square pile body 4 has a through central hole 1 in the axial direction. The end plates 2 are arranged at both ends of the square pile body 4, corresponding to the central round hole 1 on the square pile body 4, the square metal end plate 2 is also provided with the central round hole 1, and the periphery 3 of the square metal end plate 2 Welding grooves are provided, and anchor holes 6 are symmetrically provided on the square metal end plate 2 .

[0029] The reinforcement cage includes the main reinforcement 8 and the stirrup 7, the stirrup 7 is welded on the main reinforcement 8 in a spiral shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com