Insert for a sandwich component having a honeycomb core

A honeycomb core and plug-in technology, applied in the direction of connecting members, threaded fasteners, thin plate connections, etc., can solve the problems of increasing weight and production cost, and achieve the effect of large bonding diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

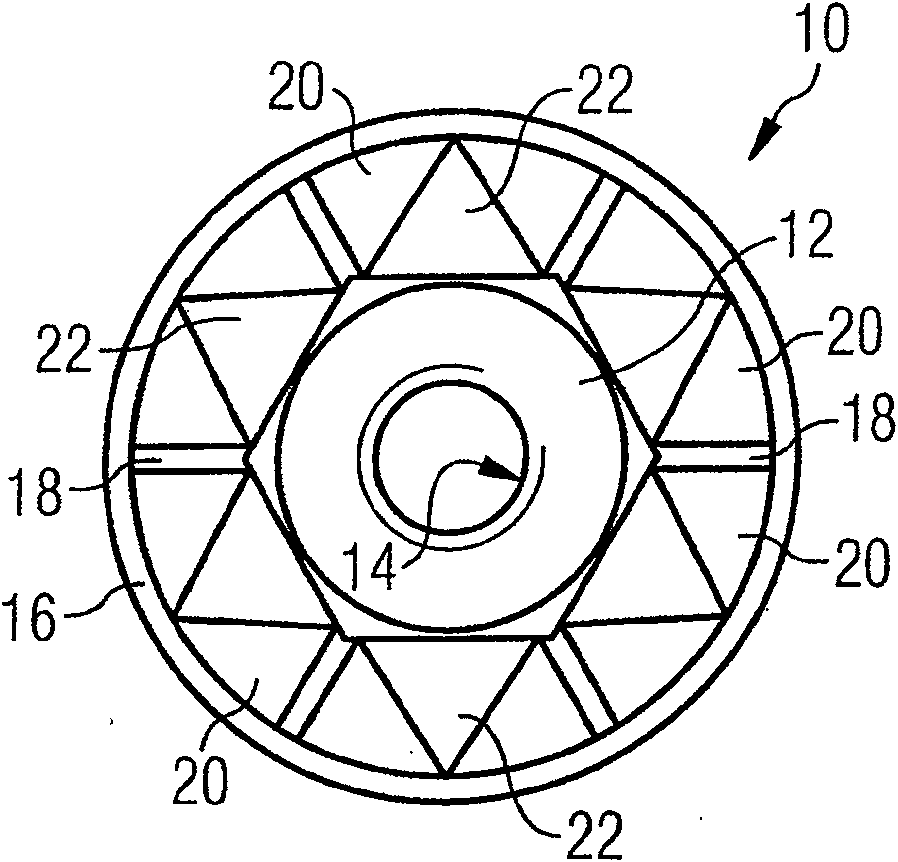

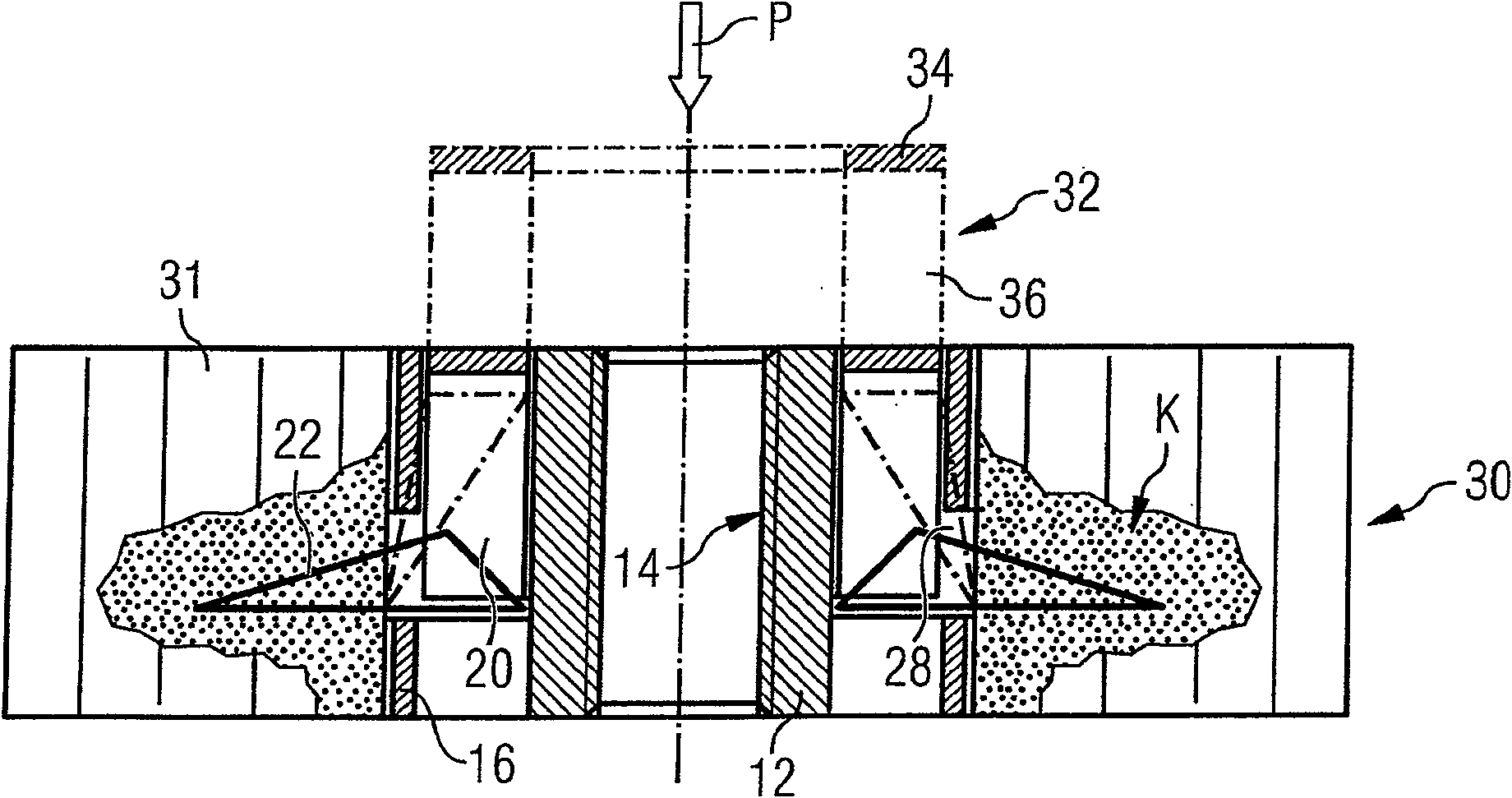

[0024] figure 1 An insert, generally indicated at 10, is shown viewed from above. The insert 10 is a part that allows the attachment of other components, such as brackets, to a sandwich component with a honeycomb core, so that forces can be transmitted between the sandwich component and the other component. The insert thus constitutes a so-called connection point between the sandwich component and the other component to be attached thereto.

[0025] The insert 10 has a hollow cylindrical inner sleeve 12, the through hole 14 of which can be designed as a threaded hole, for example. A similarly hollow cylindrical outer sleeve 16 is arranged concentrically and radially spaced relative to the inner sleeve 12, the inner side of which is connected to the inner sleeve by a plurality (in this case six) of radial webs 18 12 outside. The basic structure of the insert 10 is formed by the inner sleeve 12 , the outer sleeve 16 and the web 18 connecting the two sleeves 12 , 16 .

[0026...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com