Lysine additive and producing process thereof

A technology of lysine and additives, applied in the field of lysine additives and their preparation, can solve the problems of unstable use effect and lack of value for wide application, and achieves improvement of utilization rate, alleviation of feed protein shortage, and low release rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

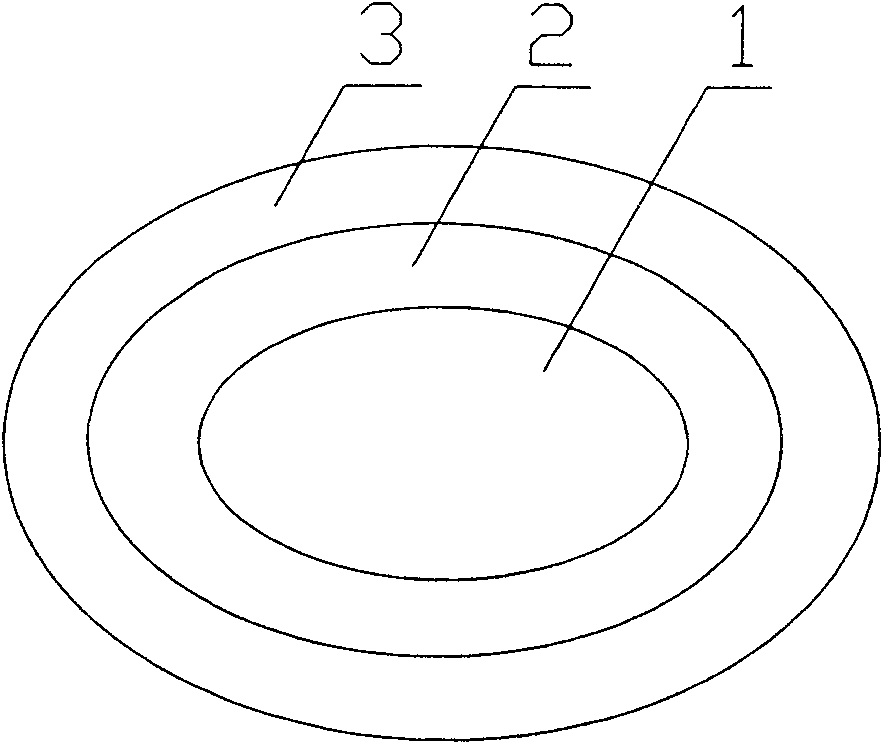

[0042] Such as figure 1 As shown, a lysine additive comprising a three-layer structure, the innermost layer is lysine 1, the middle layer is acrylic resin No. IV layer 2, and the outermost layer is a mixed layer of acrylic resin No. IV and hydrogenated vegetable oil 3.

[0043] (1) Weigh the components according to the following weight percentages:

[0044] Lysine 600g (60%);

[0045] Acrylic resin IV No. 200g (20%);

[0046] Hydrogenated vegetable oil 200g (20%).

[0047] (2) Add 30% by weight of the weighed acrylic resin IV, 60g, and anhydrous ethanol to prepare a concentration (mass volume ratio) of 30% acrylic resin IV anhydrous ethanol 200ml, add lysine to it, and stir until Granular

[0048] (3) Drying at 40~60℃;

[0049] (4) Add 50wt% of the weighed acrylic resin No. IV, namely 100g, and add anhydrous ethanol to prepare 1000ml of acrylic resin No. IV anhydrous ethanol with a concentration (mass volume ratio) of 10%, and use the dry granular lysine with this Solution coating

[0...

Embodiment 2

[0053] Such as figure 1 As shown, a lysine additive comprising a three-layer structure, the innermost layer is lysine 1, the middle layer is acrylic resin No. IV layer 2, and the outermost layer is a mixed layer of acrylic resin No. IV and hydrogenated vegetable oil 3.

[0054] (1) Weigh the components according to the following weight percentages:

[0055] Lysine 500g (50%);

[0056] Acrylic resin IV No. 200g (20%);

[0057] Hydrogenated vegetable oil 300g (30%).

[0058] (2) Add 30% by weight of the weighed acrylic resin IV, 60g, and anhydrous ethanol to prepare a concentration (mass volume ratio) of 30% acrylic resin IV anhydrous ethanol 200ml, add lysine to it, and stir until Granular

[0059] (3) Drying at 40~60℃;

[0060] (4) Add 50wt% of the weighed acrylic resin No. IV, namely 100g, and add anhydrous ethanol to prepare 1000ml of acrylic resin No. IV anhydrous ethanol with a concentration (mass volume ratio) of 10%, and use the dry granular lysine with this Solution coating

[0...

Embodiment 3

[0064] Such as figure 1 As shown, a lysine additive comprising a three-layer structure, the innermost layer is lysine 1, the middle layer is acrylic resin No. IV layer 2, and the outermost layer is a mixed layer of acrylic resin No. IV and hydrogenated vegetable oil 3.

[0065] (1) Weigh the components according to the following weight percentages:

[0066] Lysine 400g (40%);

[0067] Acrylic resin IV No. 200g (20%);

[0068] Hydrogenated vegetable oil 400g (40%).

[0069] (2) Add 30% by weight of the weighed acrylic resin IV, 60g, and anhydrous ethanol to prepare a concentration (mass volume ratio) of 30% acrylic resin IV anhydrous ethanol 200ml, add lysine to it, and stir until Granular

[0070] (3) Drying at 40~60℃;

[0071] (4) The weighed acrylic resin No. IV 50wt%, namely 100g, is added with absolute ethanol to prepare 1000ml of acrylic resin No. IV absolute ethanol with a concentration (mass volume ratio) of 12%, and the dried granular lysine is used Solution coating

[0072] (5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com