Drawer assembly

A component and drawer technology, applied in drawers, furniture parts, household appliances, etc., can solve the problem of high cost and achieve the effect of saving manufacturing cost and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

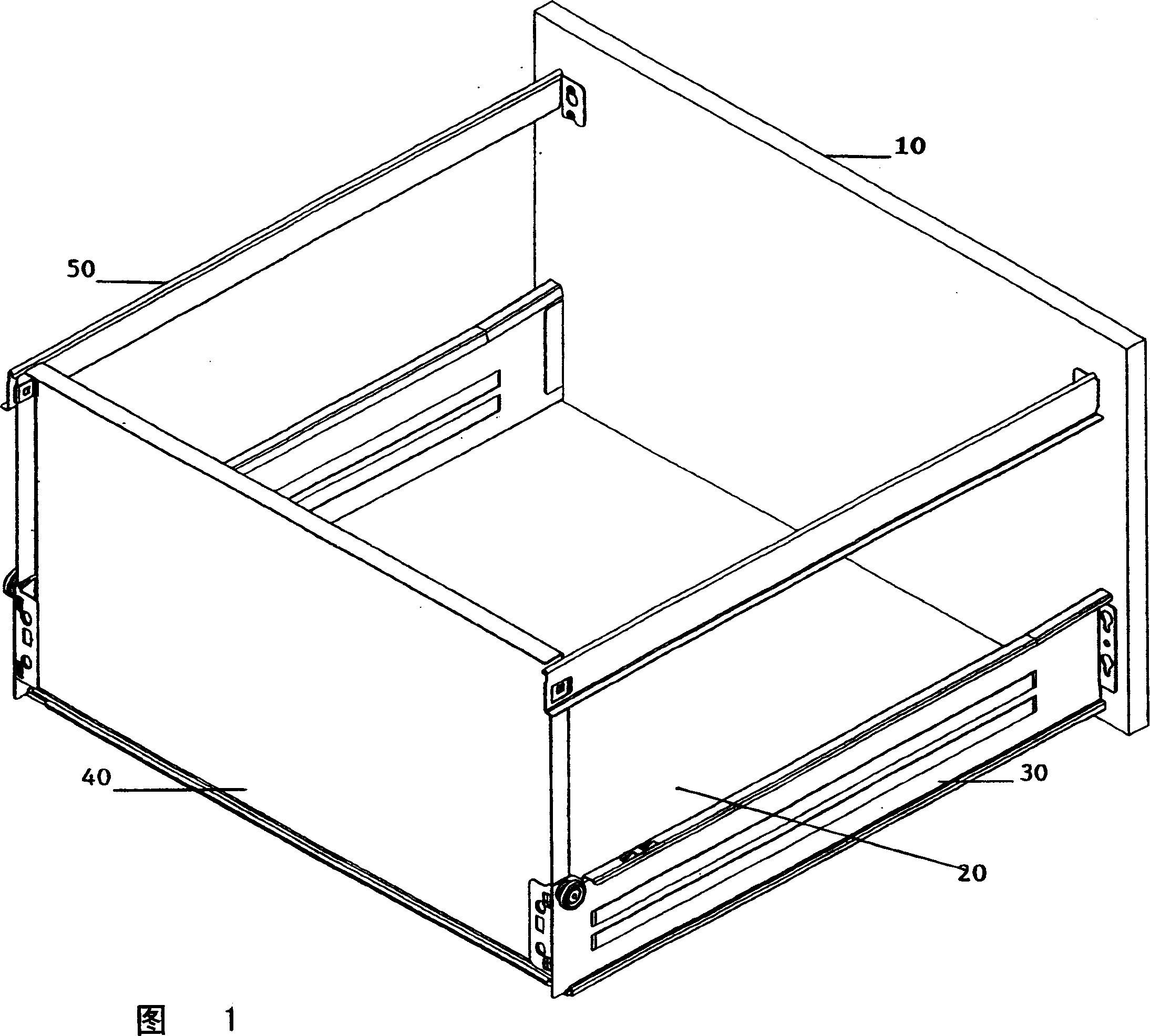

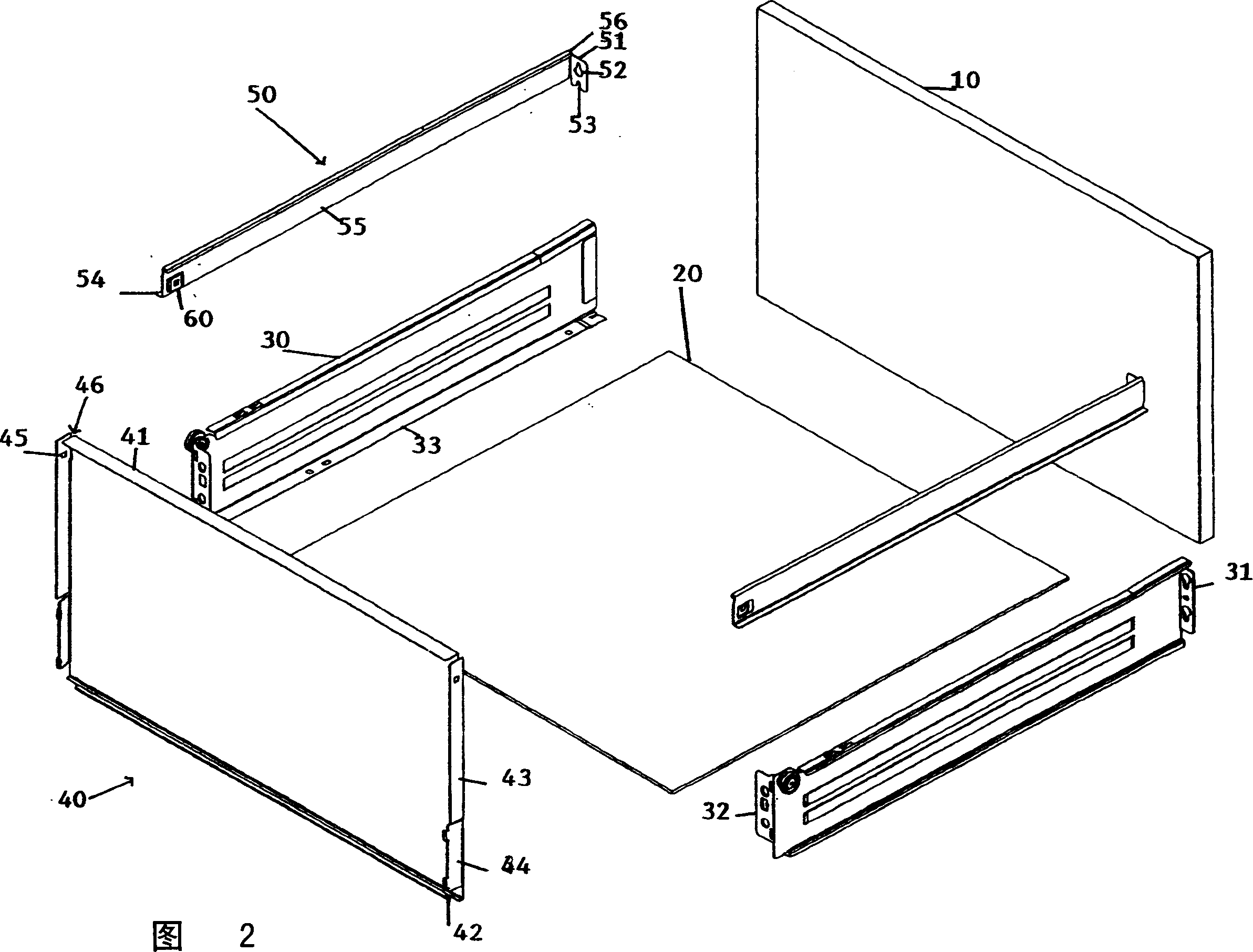

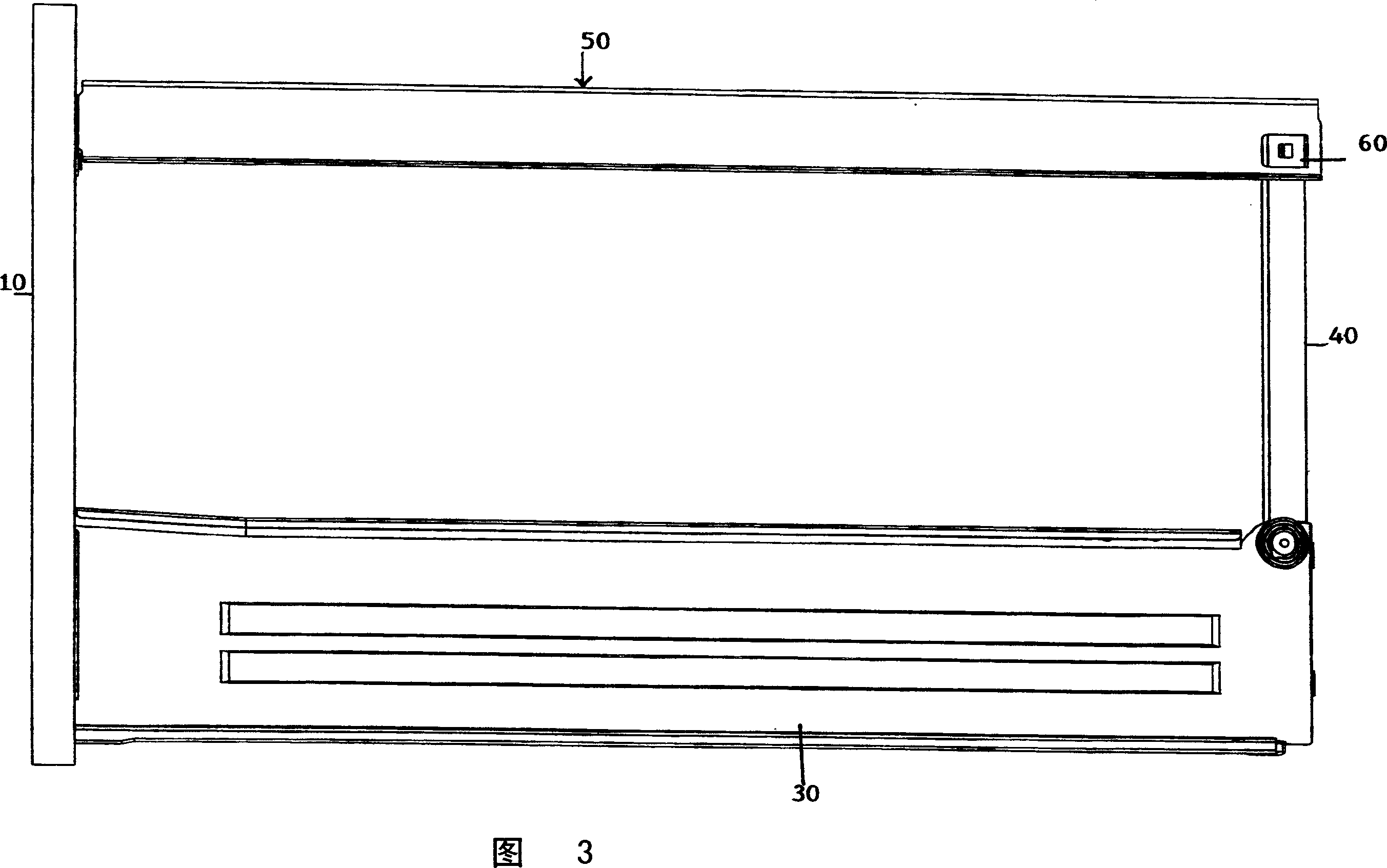

[0037] 1 to 3 illustrate a drawer assembly comprising a front panel 10 , a rear panel 40 and a bottom panel 20 , each side of the drawer assembly comprising a side panel 30 and a side rail 50 . Each side panel 30 extends between the front panel 10 and the rear panel 40 on one side of the drawer assembly, and an associated one of the side rails 50 is disposed above and upright spaced from the side panel 30 . In a preferred embodiment, the rear end of the side rail 50 is provided with a clip 60 having a locking structure and the rear panel 40 is provided with a complementary locking structure. The rear ends of the side rails 50 are attached to the rear panel 40 by interlocking the side rail locking structures with complementary rear panel locking structures. This interlocking condition is achieved by inserting portions of the rear panel 40 having complementary locking features into the side track clips 60 .

[0038] As can be seen from Figures 4A to 4C, the rear panel 40 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com