Network integrated monitoring system of suction hopper dredger

A technology of trailing suction dredger and network integration, applied in signal transmission system, electrical signal transmission system, earth mover/shovel, etc., can solve the problems of heavy wiring workload, inability to realize information sharing, and high cost, Achieve the effect of broadening condition monitoring and improving traceability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

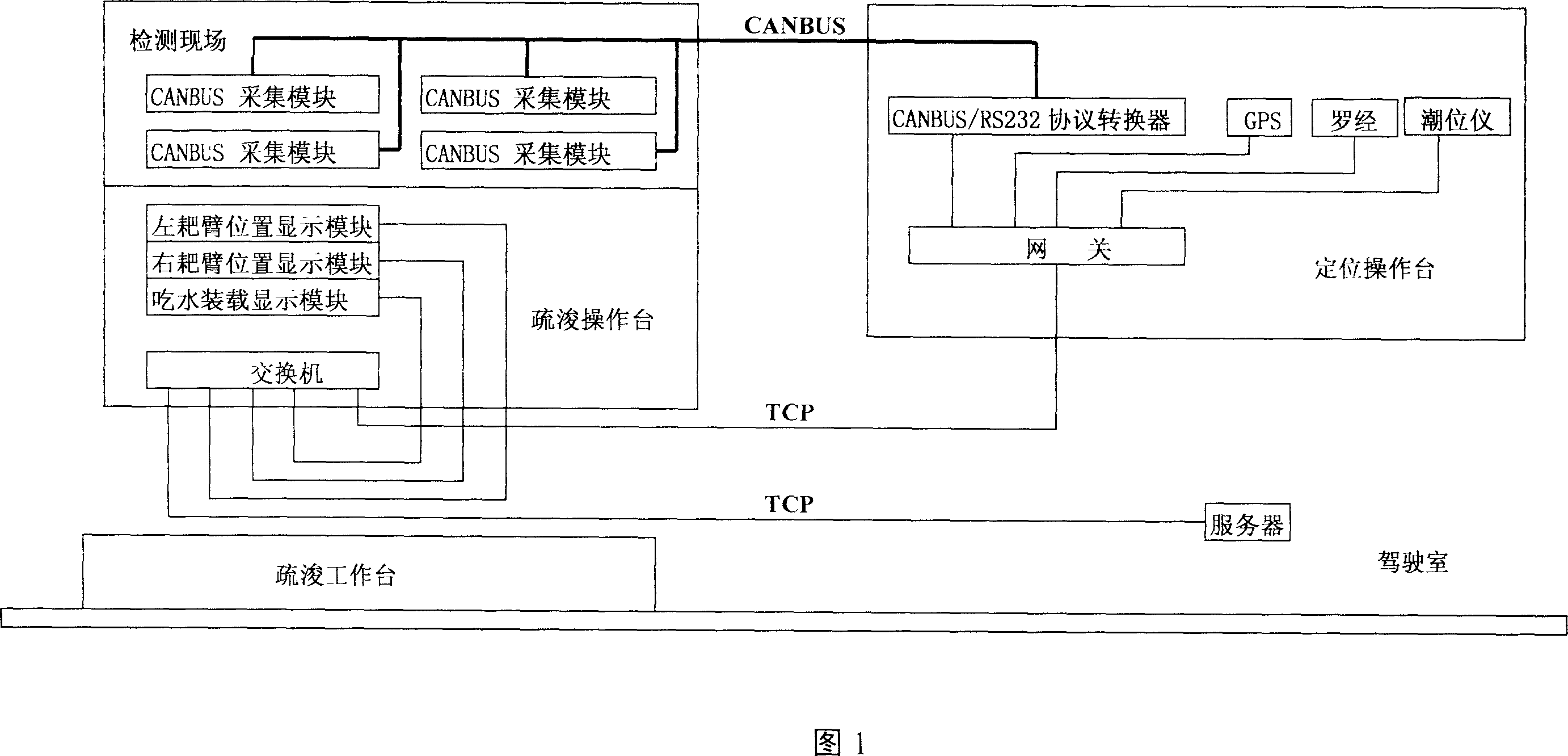

[0011] The network integrated monitoring system of the trailing suction dredger of the present invention includes two subsystems of a rake arm position indicating system and a draft loading system.

[0012] The position indication system of the rake arm is used for the positioning of the ship and the rake head, and provides the working posture of the rake arm under water during the construction process. It mainly includes the following signals: GPS, compass, tide level meter, vertical angle of the upper rake tube, vertical angle of the lower rake tube angle, the horizontal angle of the upper rake tube, the horizontal angle of the lower rake tube, the draft of the suction port and the position of the suction port.

[0013] The draft loading system is used to monitor the loading status of the ship during the construction process, including ship draft, tank capacity, loading volume, earthwork volume, etc. Mainly include the following signals: bow draft, stern left draft, stern ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com