Method for manufacturing an optical film, apparatus for manufacturing the same, optical film, polarizing plate and image display device

An optical film and film technology, applied in the device, optics, polarizing element and other directions of coating liquid on the surface, can solve the problems of not getting film, uneven visual color, quality problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0112] Best Mode for Carrying Out the Invention

[0113] Hereinafter, the present invention will be described in detail. In this specification, "(numerical value 1) to (numerical value 2)" means "not less than (numerical value 1) but not more than (numerical value 2)" when numerical values represent physical property values, characteristic values, etc.

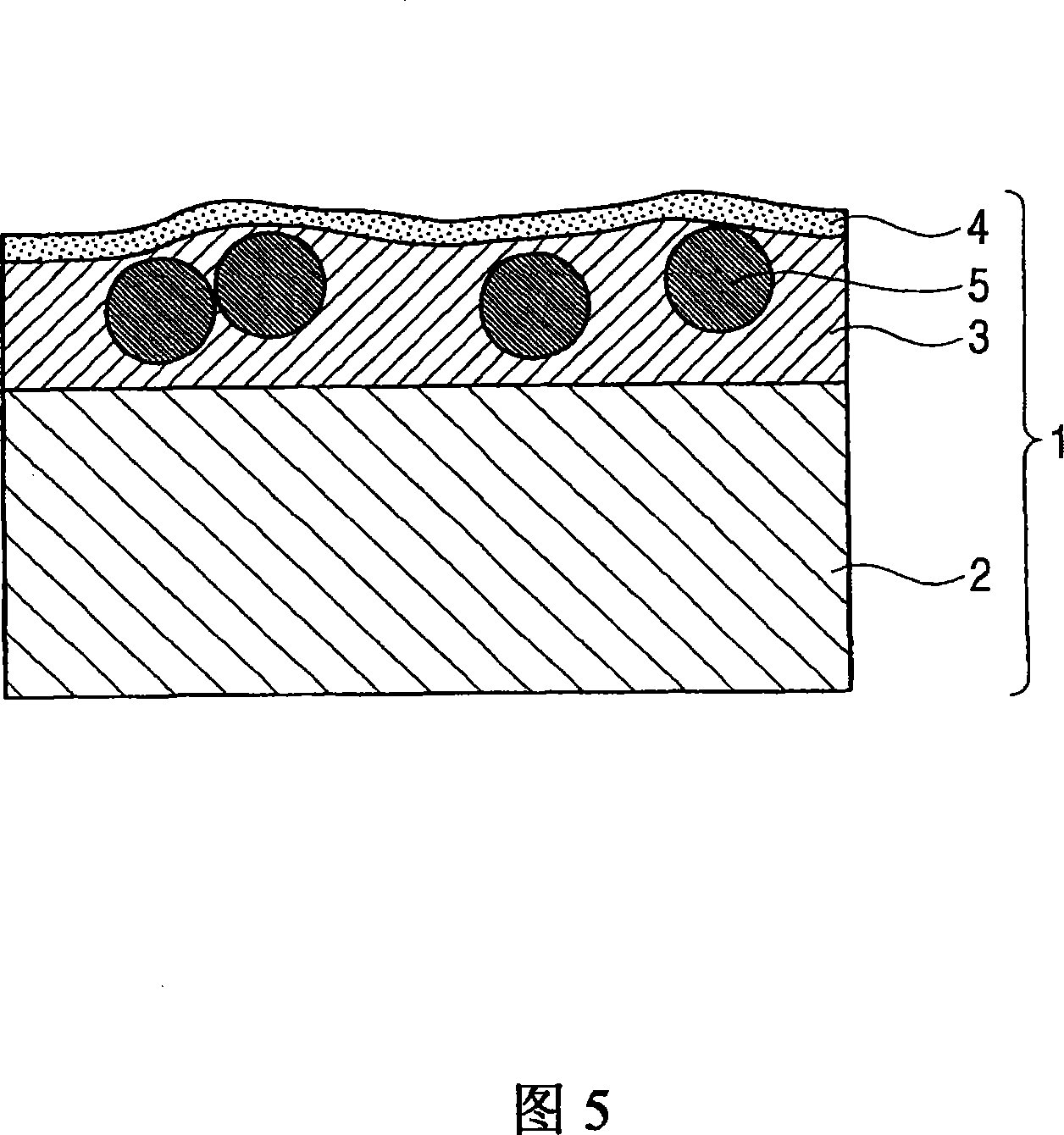

[0114] [Layered structure of optical film]

[0115]The optical film of the present invention has at least one functional layer on a transparent substrate (hereinafter sometimes referred to as a substrate film). In this case, the functional layer includes, for example, an antistatic layer, a hard coat layer (cured resin layer), an antireflection layer, an antiglare layer, an optional compensation layer, an alignment layer, and a liquid crystal layer. Wherein, when necessary, the antireflection film of the present invention has a hard coat layer (described below) on a transparent substrate, and also has an antireflection lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap