Composite embroidering needle bar rack set of computer embroidering machine

A needle bar frame and embroidery machine technology, applied in the field of garment machinery, can solve the problems of increasing machine weight and volume, affecting embroidery efficiency, limiting distance, etc., and achieve the goals of reducing equipment weight and volume, increasing embroidery area, and improving work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

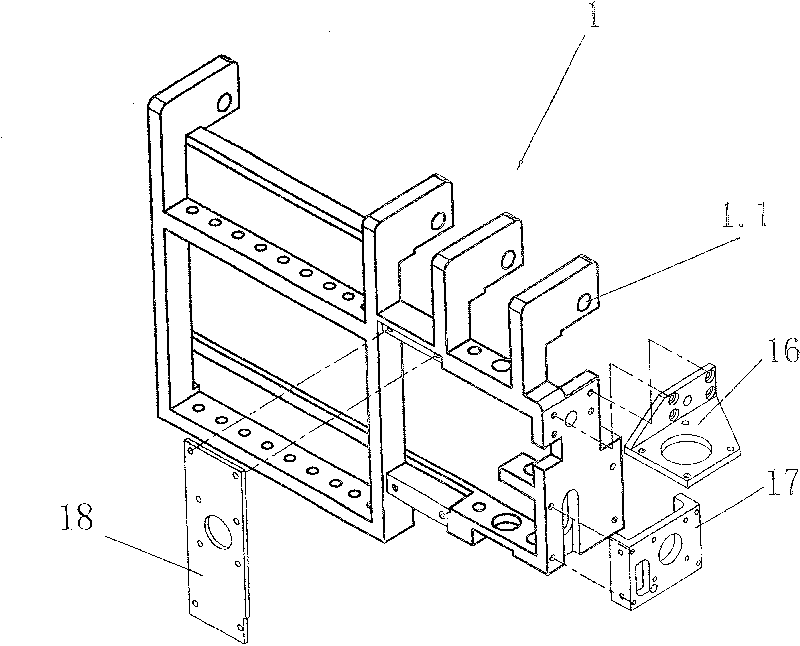

[0020] refer to figure 1 , the needle bar frame 1 has three notches with different widths from the upper part, the wide slot on the left is used to install the flat embroidery needle bar mechanism 4, and the narrow slot on the right is used to install the tape embroidery mechanism 3, which is different from the original needle bar Compared with the frame, the needle bar frame 1 of the present invention has increased the volume of the two narrow grooves on the right side. The upper and lower sides of the right side of the needle bar frame 1 are respectively screw-connected with the gear embroidery shaft drive motor seat 16 and the rope swing motor seat 17, and the front of the middle part of the needle bar frame 1 is installed with the tape embroidery presser foot lifting motor seat 18, and the mark 1.1 in the figure is for supply. A shaft hole through which the shaft of the wire rod passes.

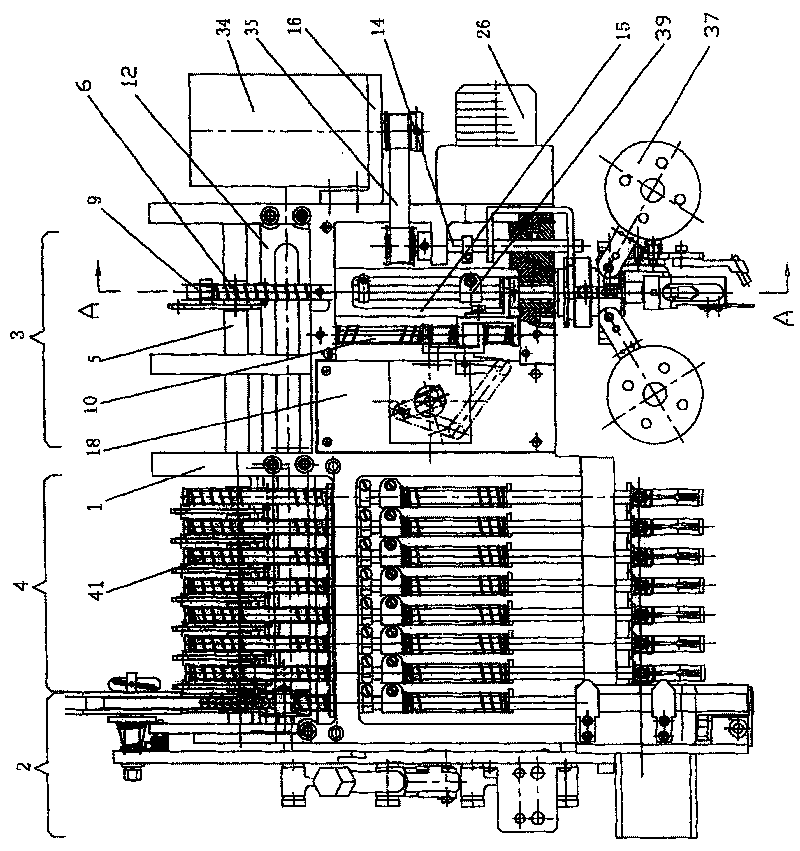

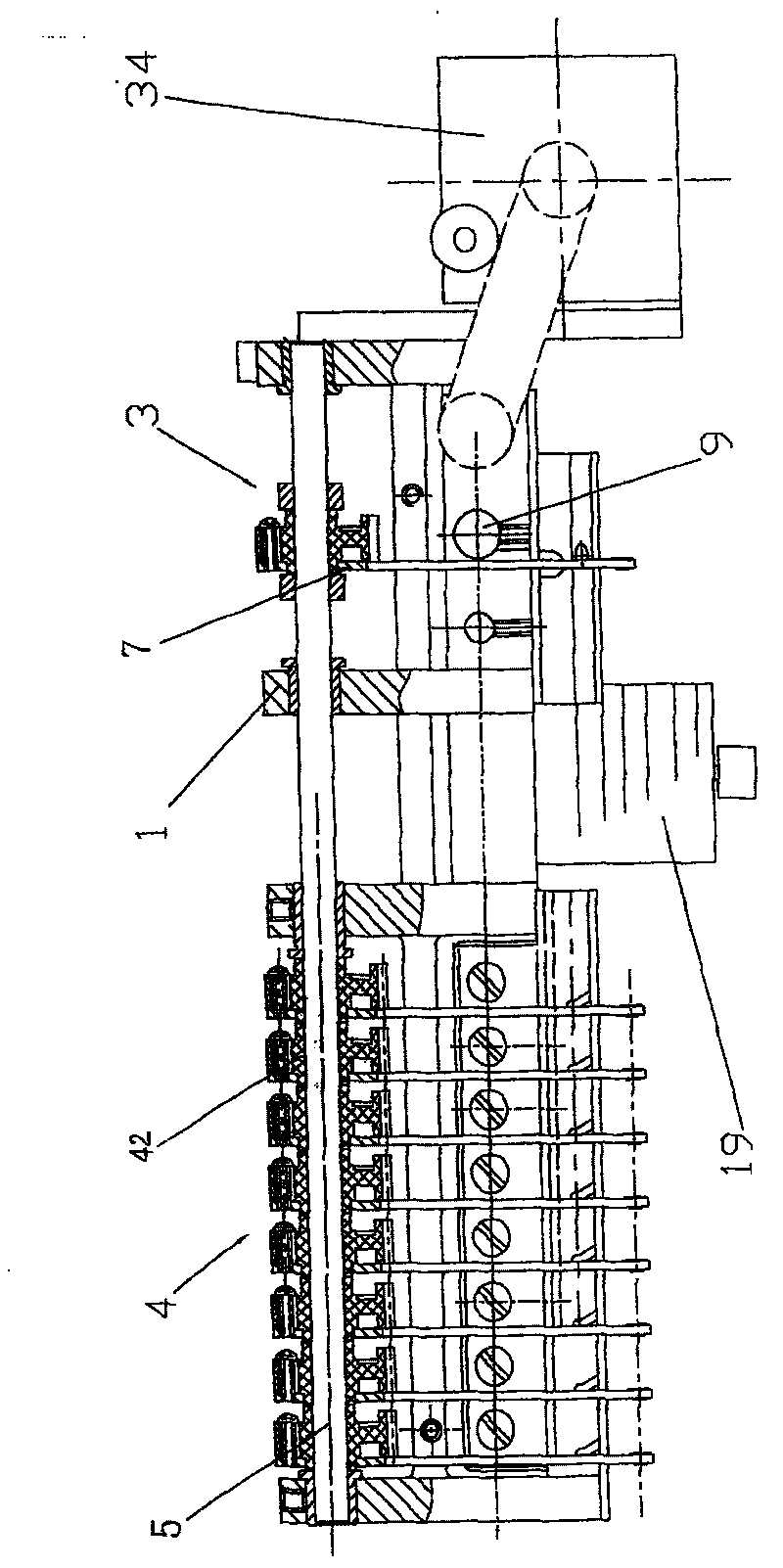

[0021] refer to figure 2 , image 3 , the sequin embroidery mechanism 2 is instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com