Lens module

A lens module and lens barrel technology, which is applied in installation, optics, instruments, etc., can solve the problems of the strength and adjustment accuracy of the focusing mechanism, shorten the service life of the lens module, and affect the shooting quality, etc., and achieves simple structure, low cost, and reduced The effect of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

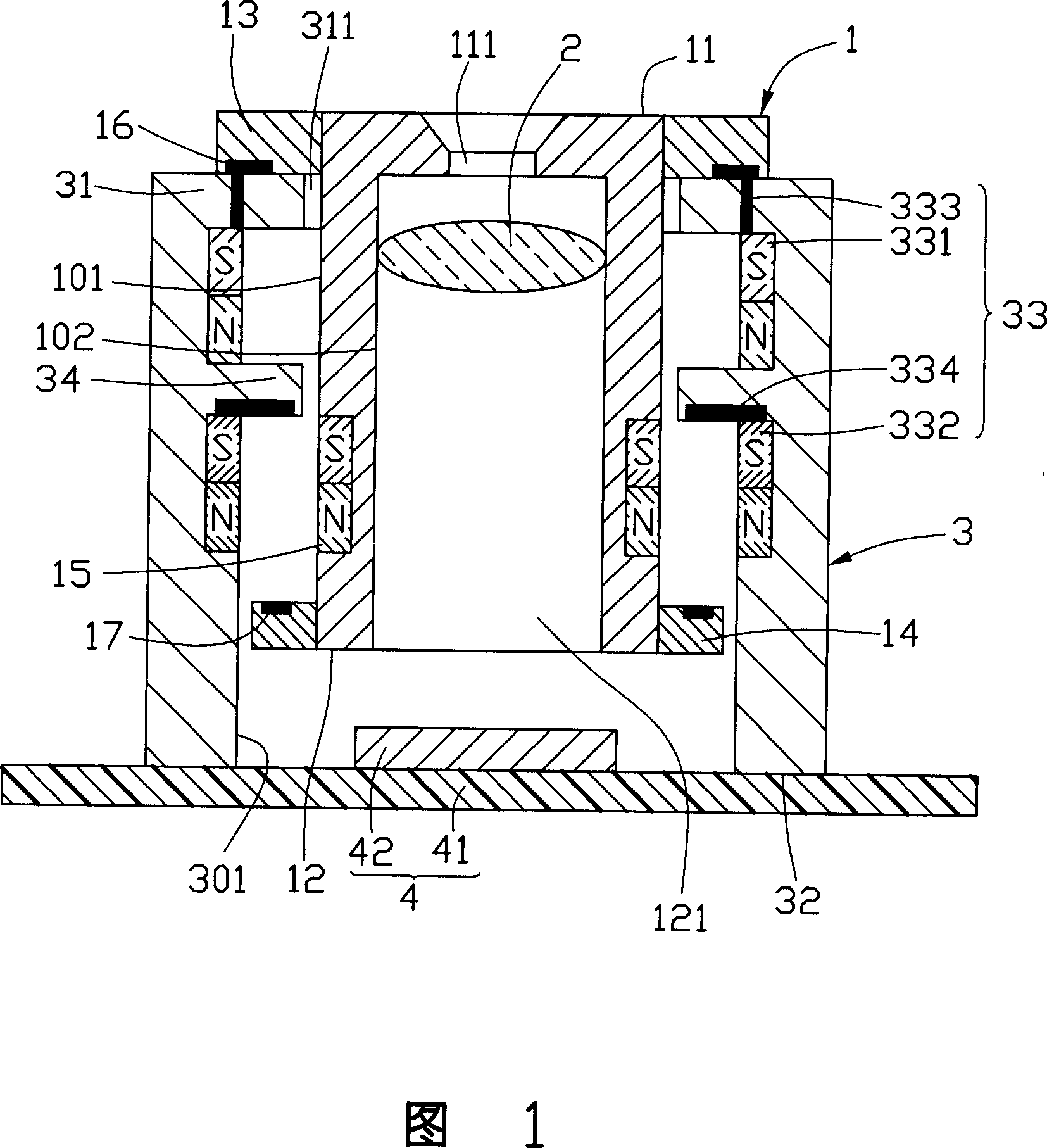

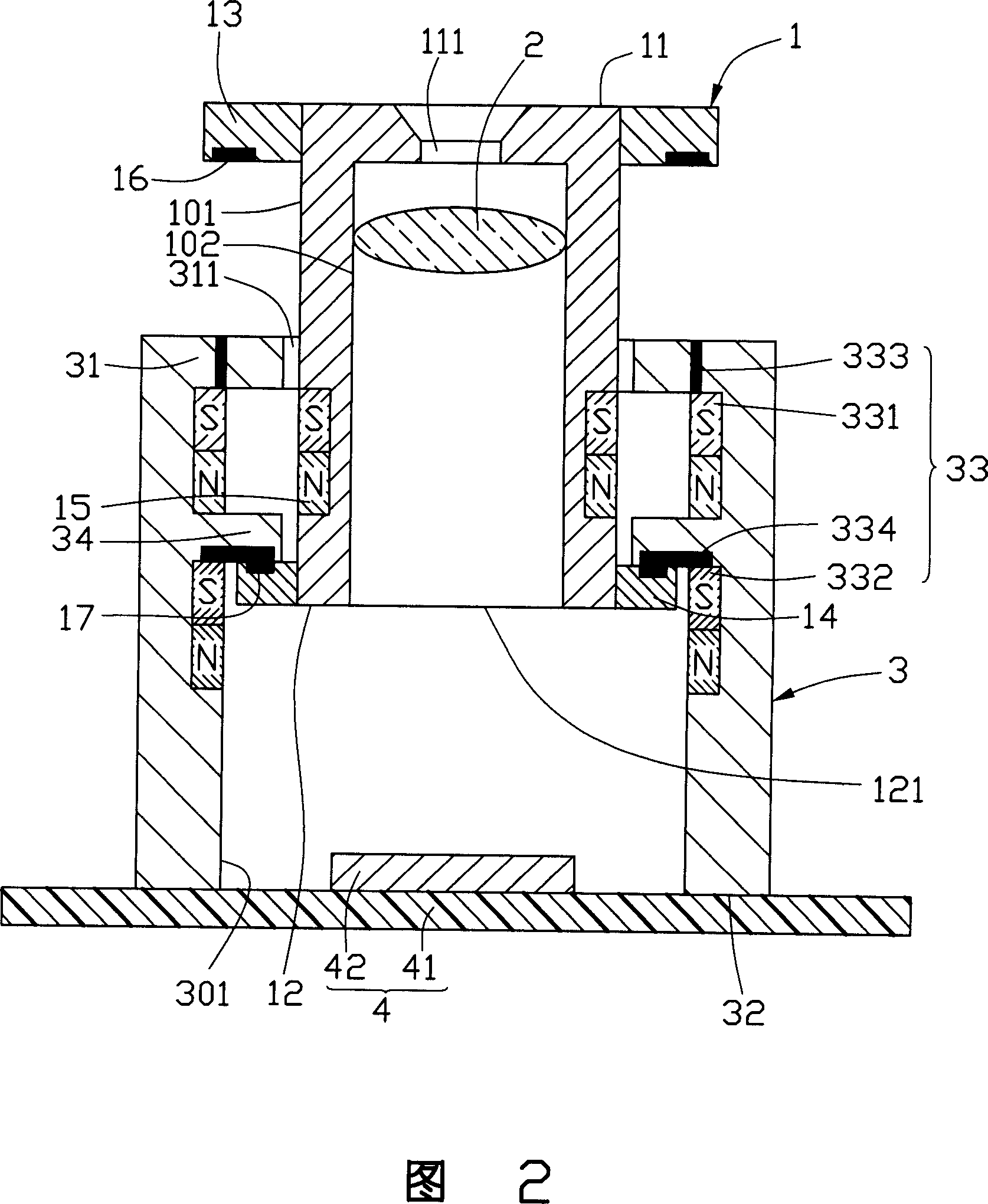

[0008] Please refer to FIG. 1 , a preferred embodiment of the lens module of the present invention includes a lens barrel 1 , a lens 2 and a sleeve 3 . Wherein the lens 2 is installed inside the lens barrel 1 , and the lens barrel 1 is installed inside the sleeve 3 . An image sensing module 4 is mounted on one end of the sleeve 3 for receiving optical image signals from the lens 2 .

[0009] The lens barrel 1 is a hollow cylinder, which includes an outer cylindrical surface 101, an inner cylindrical surface 102, a shooting end 11 and a sensing end 12, wherein the shooting end 11 and the sensing end 12 are respectively arranged on the lens barrel 1, and the shooting end 11 is provided with a shooting opening 111, and the sensing end 12 is provided with a sensing opening 121. The lens barrel 1 further includes a front stopper 13 , a rear stopper 14 , an adjusting magnet 15 , a first positioning part 16 and a second positioning part 17 . The front stopper 13 is a ring, which is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com