Liquid crystal display faceplate, and base plate of array in active mode

A technology for liquid crystal display panels and array substrates, which is used in static indicators, nonlinear optics, instruments, etc., can solve the problems of display screen flicker, unbalance, and reduce the display quality of the display panel, so as to reduce parasitic capacitance and improve quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

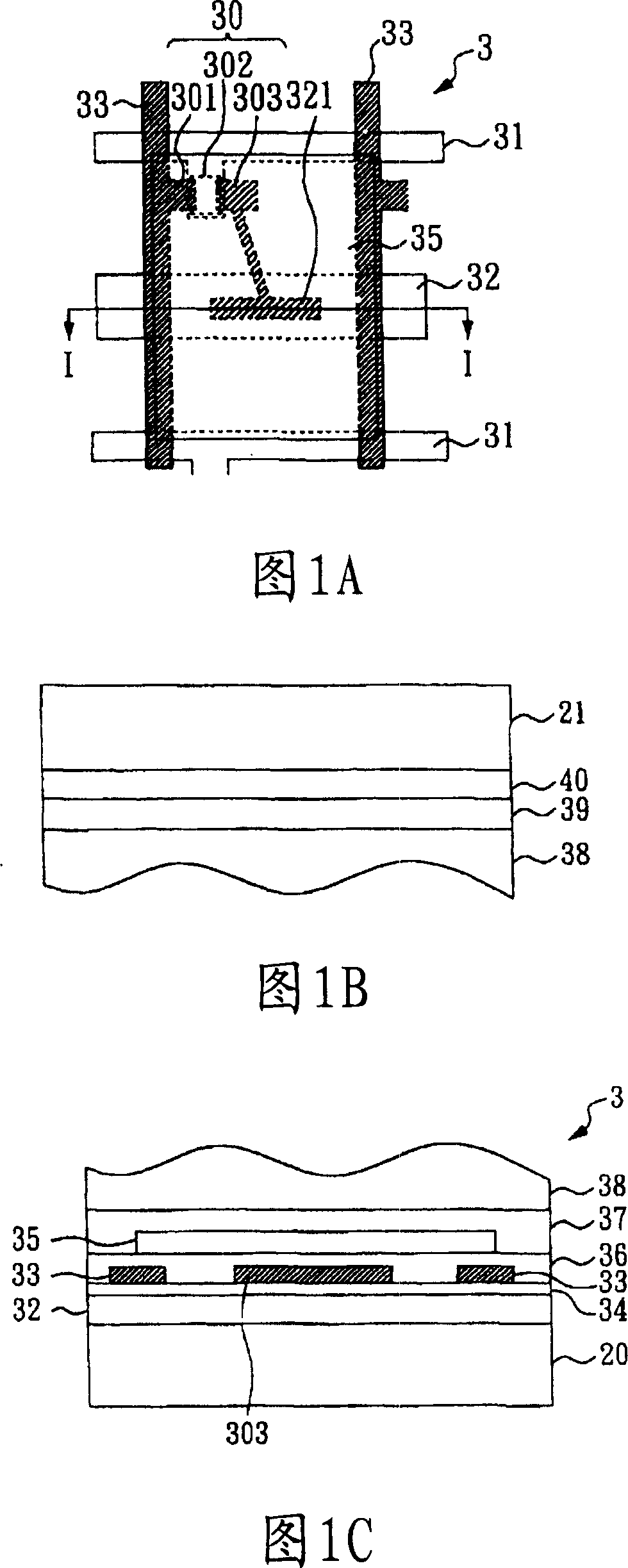

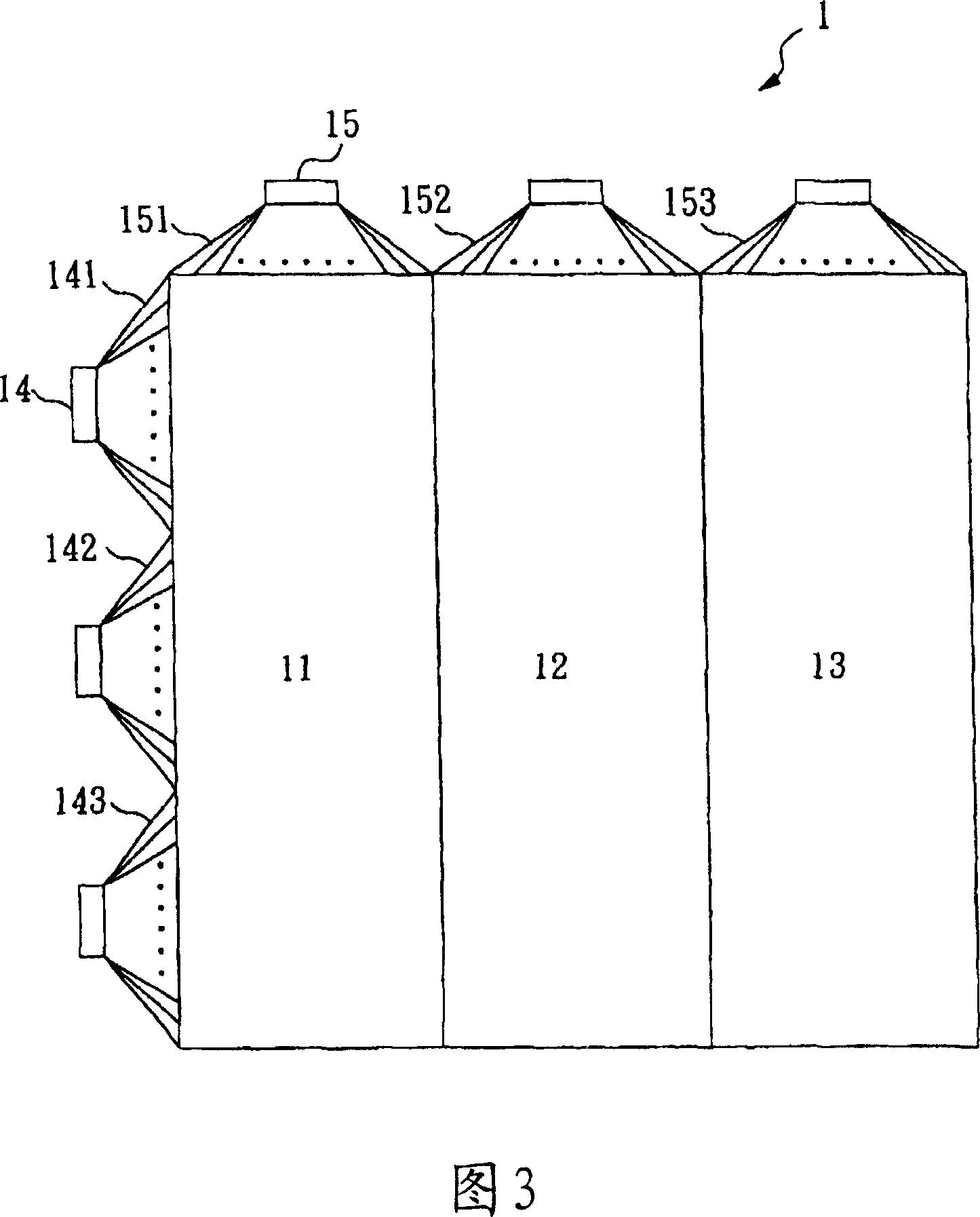

[0053] First, please refer to FIG. 3 and FIG. 4A, FIG. 4B, and FIG. 4C, wherein FIG. 3 is a schematic diagram showing sub-regions, and FIG. 4A, FIG. 4B, and FIG. 4C show a preferred embodiment of the present invention.

[0054] The lower substrate (not shown) of the liquid crystal display panel 1 is divided into display sub-regions 11, 12, 13, and the three display sub-regions respectively have a plurality of pixels 21, pixels 22 and pixels 23, and a plurality of gate driver chips 14, and a plurality of source driver chips 15, and in this embodiment, the projected areas of the display sub-regions 11, 12, and 13 are all the same.

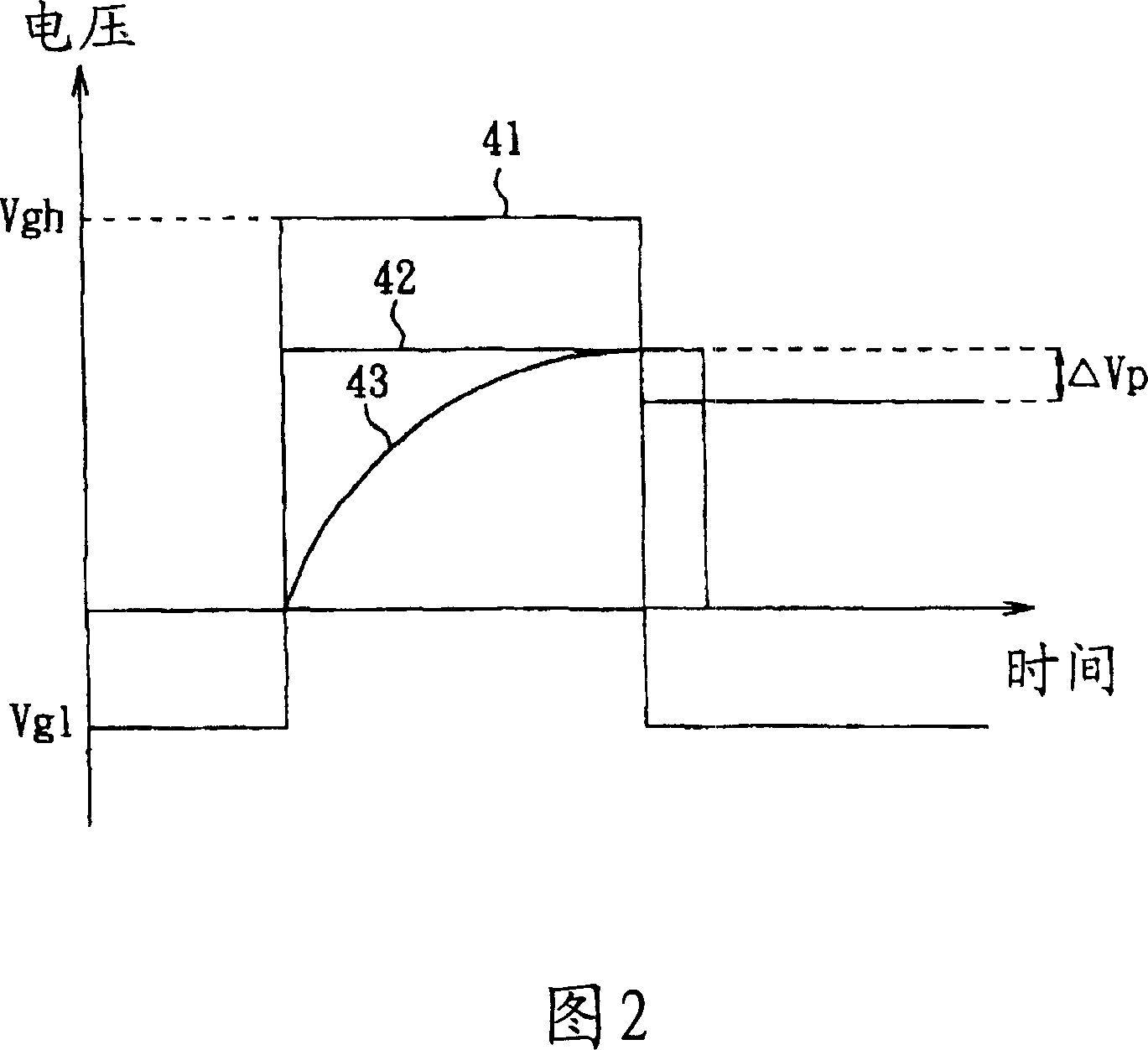

[0055] The pixels 21 , 22 , 23 respectively have a thin film transistor 30 and pixel electrodes 211 , 221 , 231 . The thin film transistor 30 includes a source 301 , a gate 302 , and a drain 303 . Moreover, the pixels 21, 22, 23 are electrically connected to the gate driver chip 14 through the gate 302 via the gate lines 141, 142, 143, and the pixels...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap