Induction code switch

A coding switch and inductive switch technology, applied in the field of switches, can solve the problems of the influence of shell strength, damage to the shell integrity of electrical equipment, poor sealing performance of electrical equipment, etc., and achieve the effect of maintaining integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

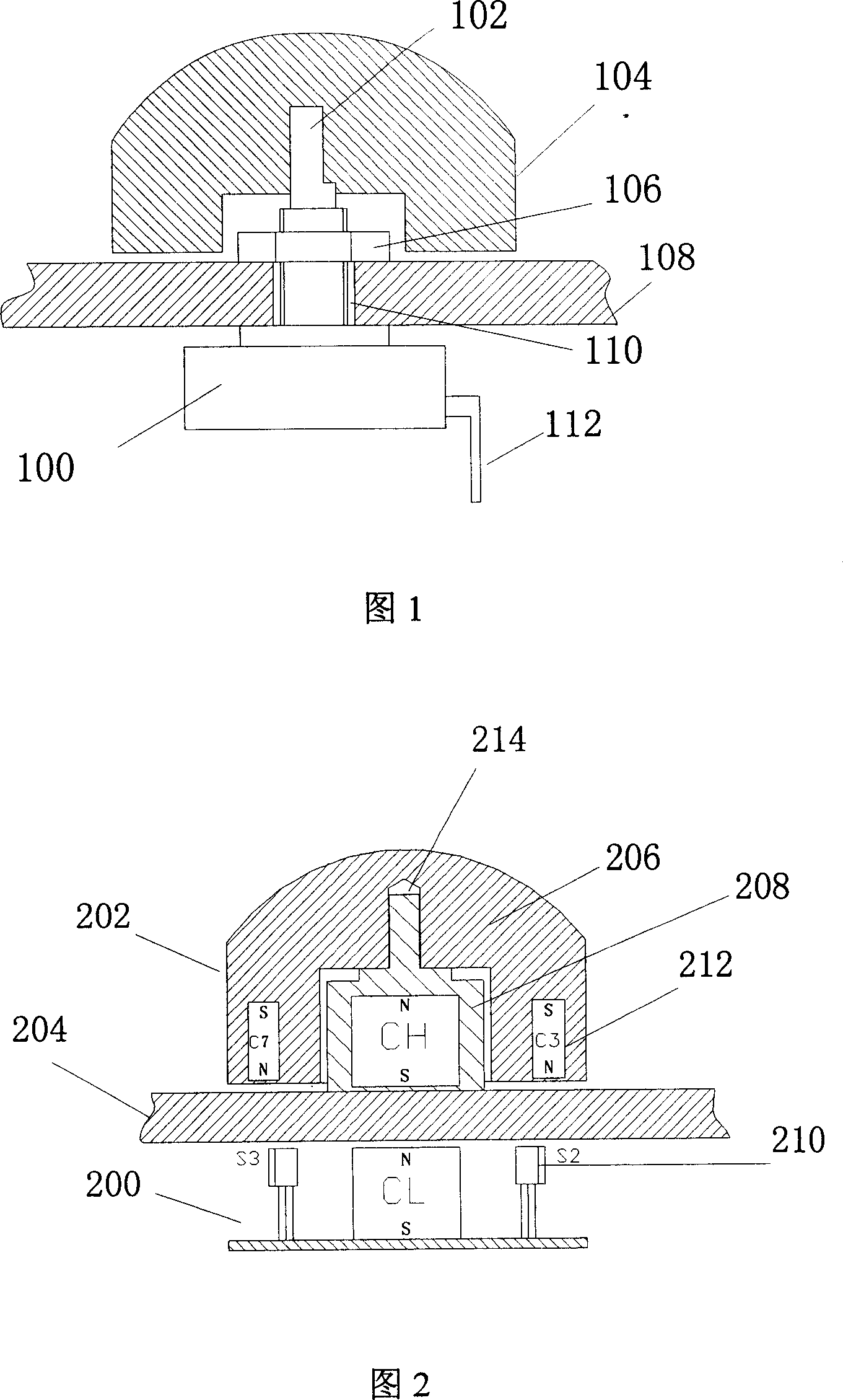

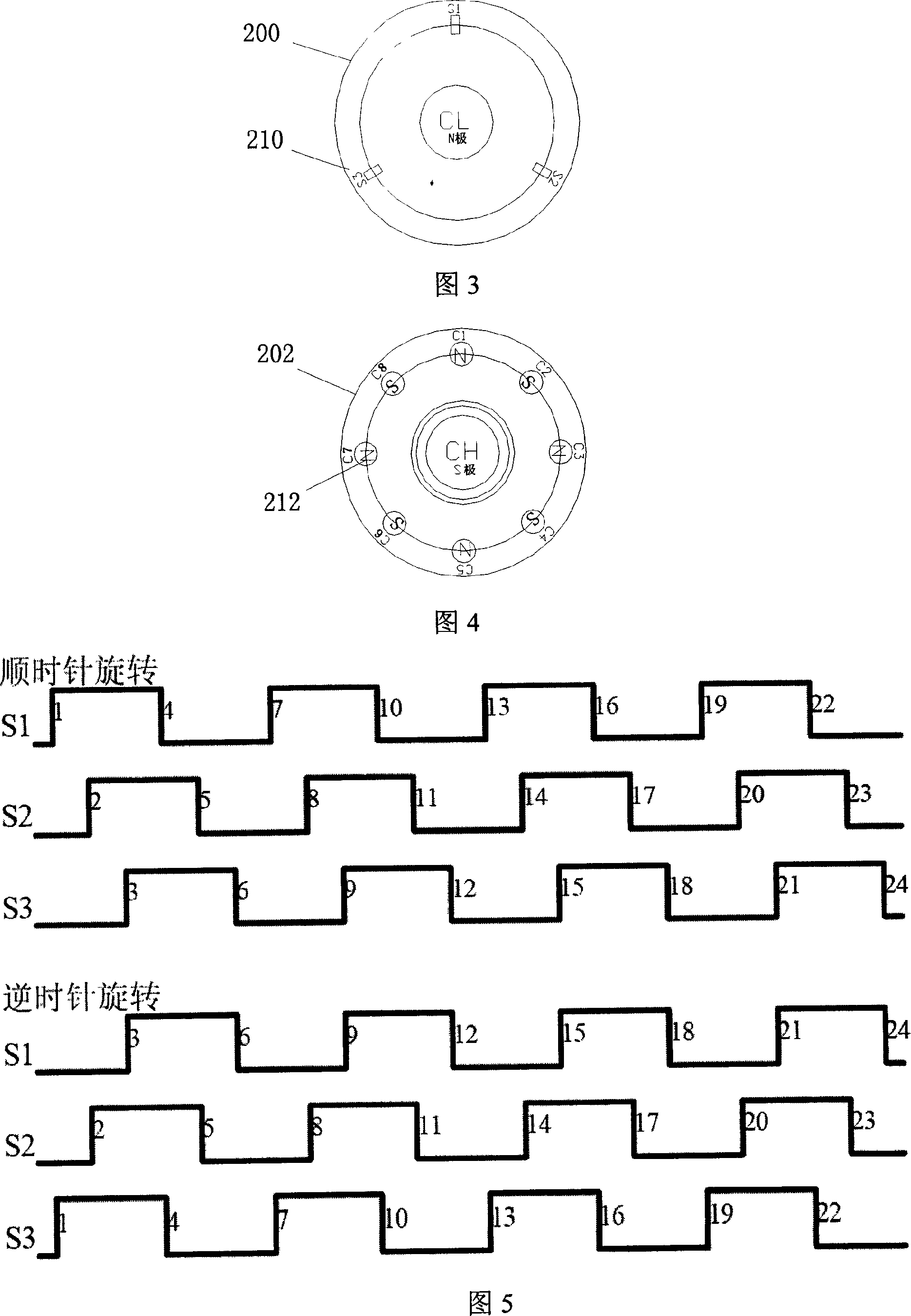

[0019] As shown in FIG. 2, an inductive coding switch includes an inductive switch plate 200 and an inductive knob 202. The inductive switch plate 200 and the inductive knob 202 are placed on both sides of an operation panel 204 (the operation panel here is a glass panel), And by the mutual attraction of the first permanent magnet CL in the center of the induction switch plate 200 and the second permanent magnet CH in the center of the induction knob 202, the induction switch plate 200 includes n ( n>=3) Hall switches 210, the induction knob 202 includes a base 208 for fixing the second permanent magnet, a knob 206 mounted on the base 208, and a knob 206 evenly distributed on the same circumference of the inner shell of the knob m (m is an even number) permanent magnets, and by rotating the knob 206, a magnetic field that changes relative to the induction switch plate 200 is generated.

[0020] In order to ensure that two or more Hall switches 210 do not turn off to on at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com