Refrigerator warehouse

A technology for a refrigerator and a storage room, which is applied in the field of refrigerators, can solve problems such as a mechanism that cannot use defrost water to evaporate, and achieves the effects of improving storage, increasing storage volume, and improving convenience of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

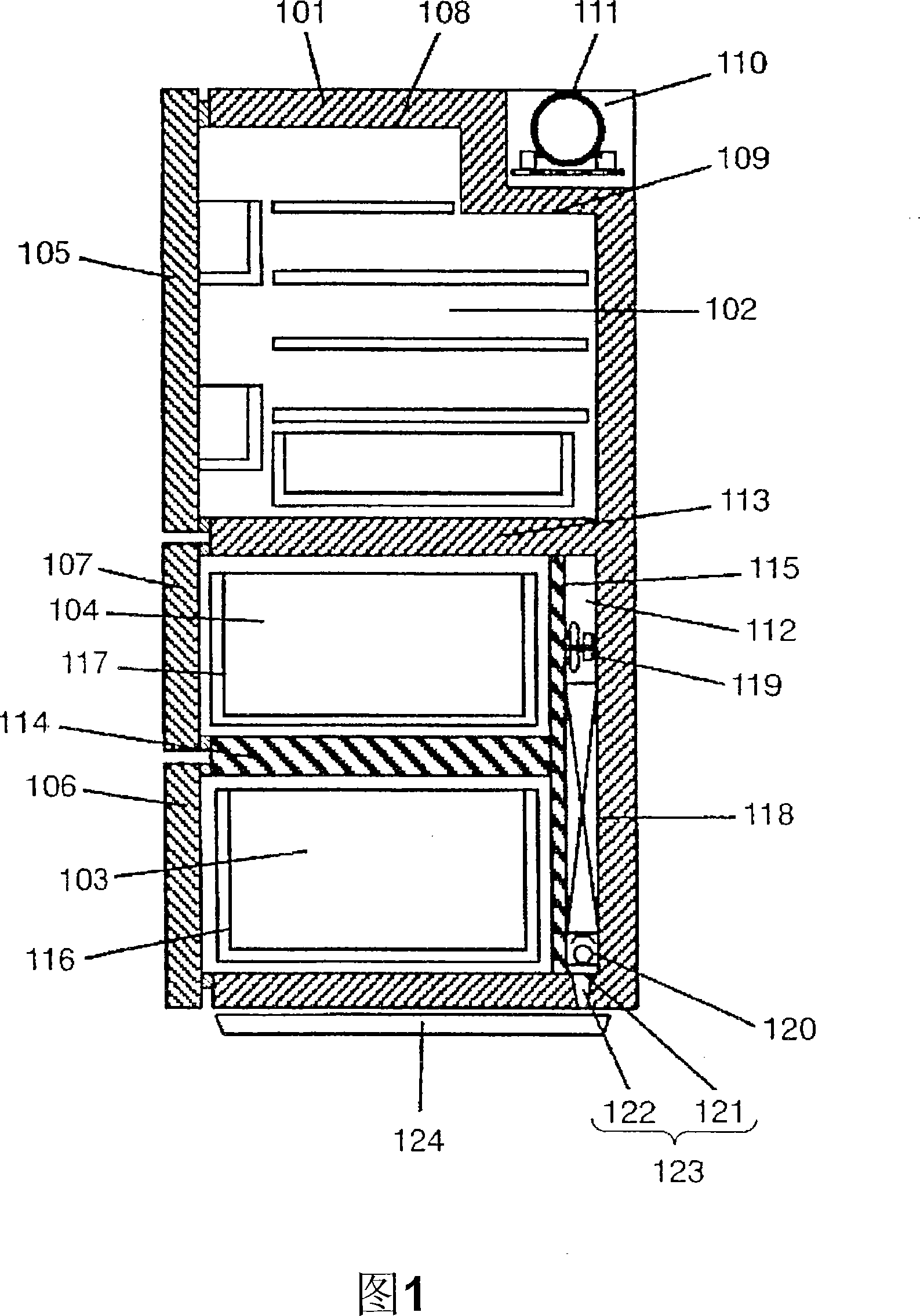

[0053] FIG. 1 is a longitudinal cross-sectional view showing the refrigerator according to Embodiment 1 of the present invention.

[0054] In FIG. 1, for example, the heat insulation box 101 comprised by the heat insulation material, such as hard foaming urethane, insulates the surroundings, is partitioned into a some area|region. It is configured such that the refrigerator compartment 102 is arranged at the uppermost part, and the freezer compartment 103 as the first storage compartment is arranged at the lowermost part. In addition, between the refrigerator compartment 102 and the freezer compartment 103, the vegetable compartment 104 as the second storage compartment is arranged. It is arranged directly above the freezing compartment 103. Both the freezing compartment 103 and the vegetable compartment 104 have the form of a drawer type storage compartment. The refrigerating compartment revolving door 105, the freezer compartment drawer door 106, and the vegetable compartment dr...

Embodiment approach 2

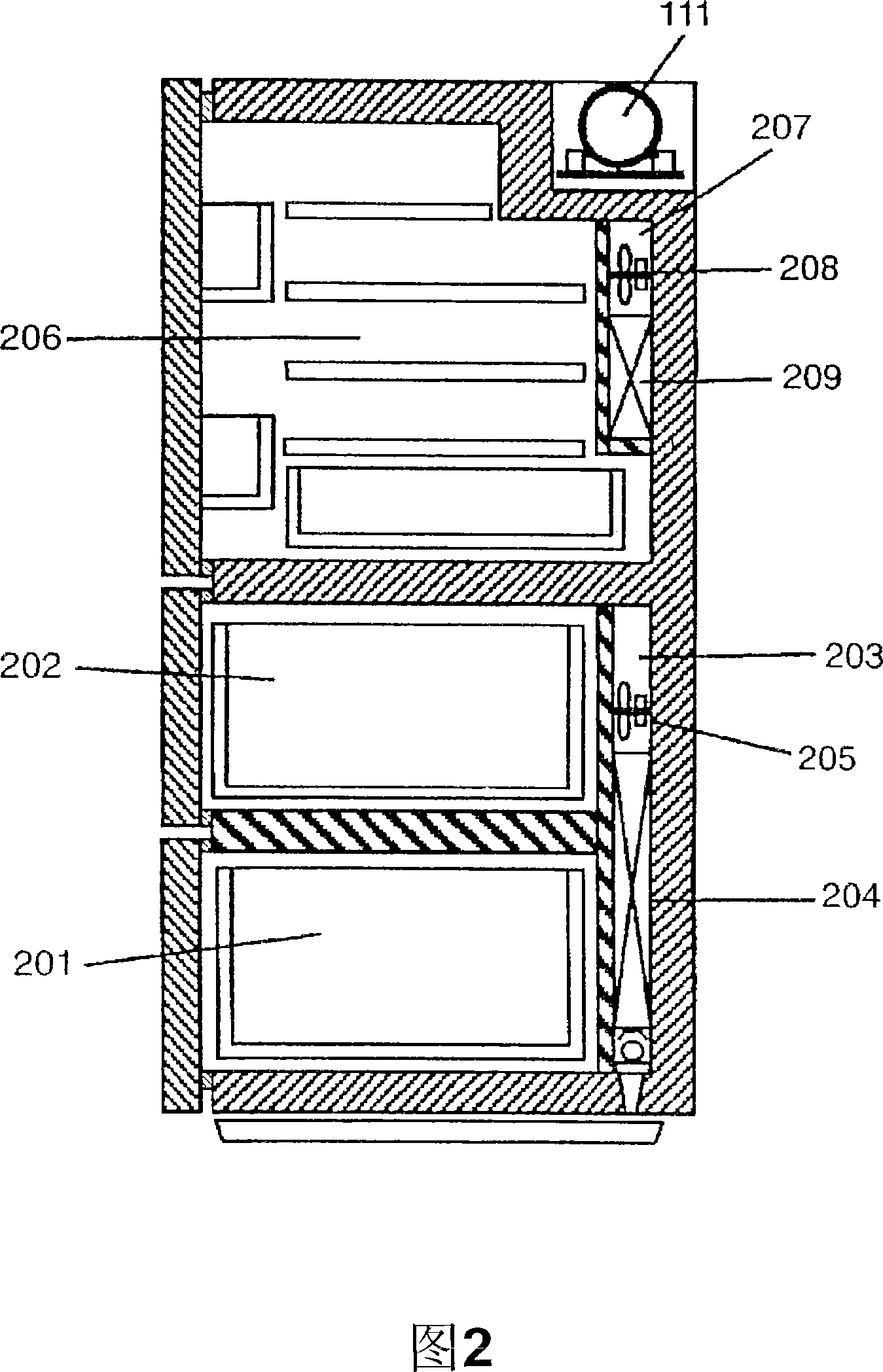

[0109] Fig. 2 is a longitudinal cross-sectional view of the refrigerator according to Embodiment 2 of the present invention. In addition, the same reference numerals are used for the same configurations as those of the first embodiment, and the description is omitted.

[0110] The first cooling chamber 203 is partitioned in the vertical direction in the back area of the freezing compartment 201 and the vegetable compartment 202. A first evaporator 204 and a first cooling fan 205 are provided in the first cooling chamber 203. The cooling chamber 201 in the freezing temperature zone is cooled by forced convection. In addition, a second cooling chamber 207 is provided on the back of the refrigerating chamber 206, and the second evaporator 208 and the second cooling fan 209 are housed therein. The evaporation temperature is made higher than the first evaporator 204, and the refrigerating compartment 206 and the vegetable compartment 202 in the refrigerating temperature zone are cool...

Embodiment approach 3

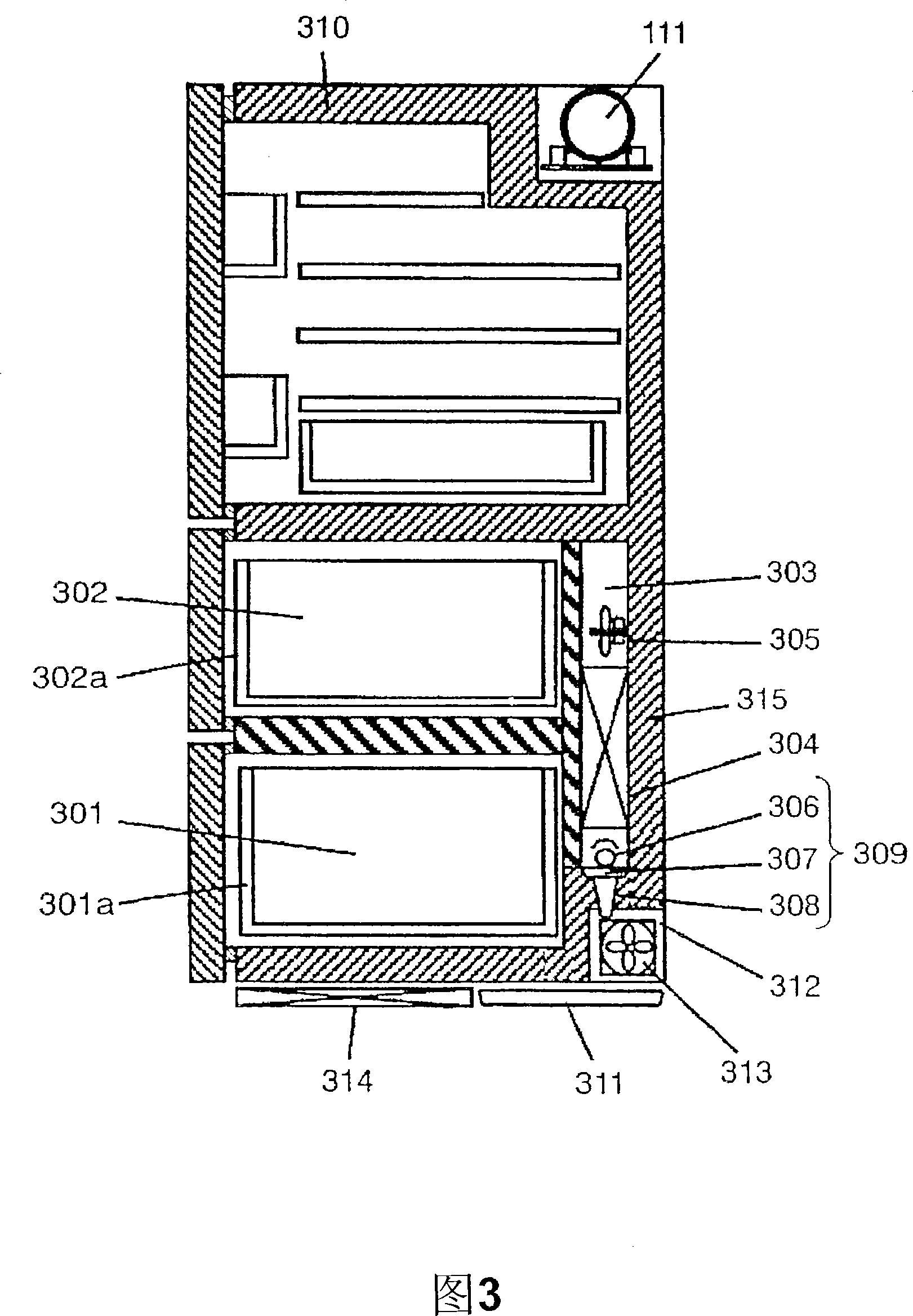

[0116] 3 is a longitudinal cross-sectional view of the refrigerator according to Embodiment 3 of the present invention. In addition, the same reference numerals are used for the same configurations as those of the first embodiment, and the description is omitted. In the back area of the freezing compartment 301 and the vegetable compartment 302, a cooling compartment 303 is partitioned in the vertical direction. An evaporator 304 and a cooling fan 305 arranged on the upper part of the evaporator 304 are installed in the cooling chamber 303.

[0117] A glass tube radiant heater 306 is installed in the lower space of the evaporator 304 as a defrosting device for removing frost attached to the evaporator 304 and the cooling fan 305 during cooling.

[0118] In addition, the defrosting water drainage mechanism 309 is arranged to be generally accommodated in the projection plane projected from above the cooling chamber 303, and the defrosting water drainage mechanism is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com