Switch of magnetic suspension train

A magnetic levitation and rotating ground technology, applied in transportation and packaging, railway car body parts, mechanical equipment for manipulating turnouts or line breakers, etc., can solve the problem of high partial load, complexity and cost of sliding bearings, shortening the life of sliding bearings And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

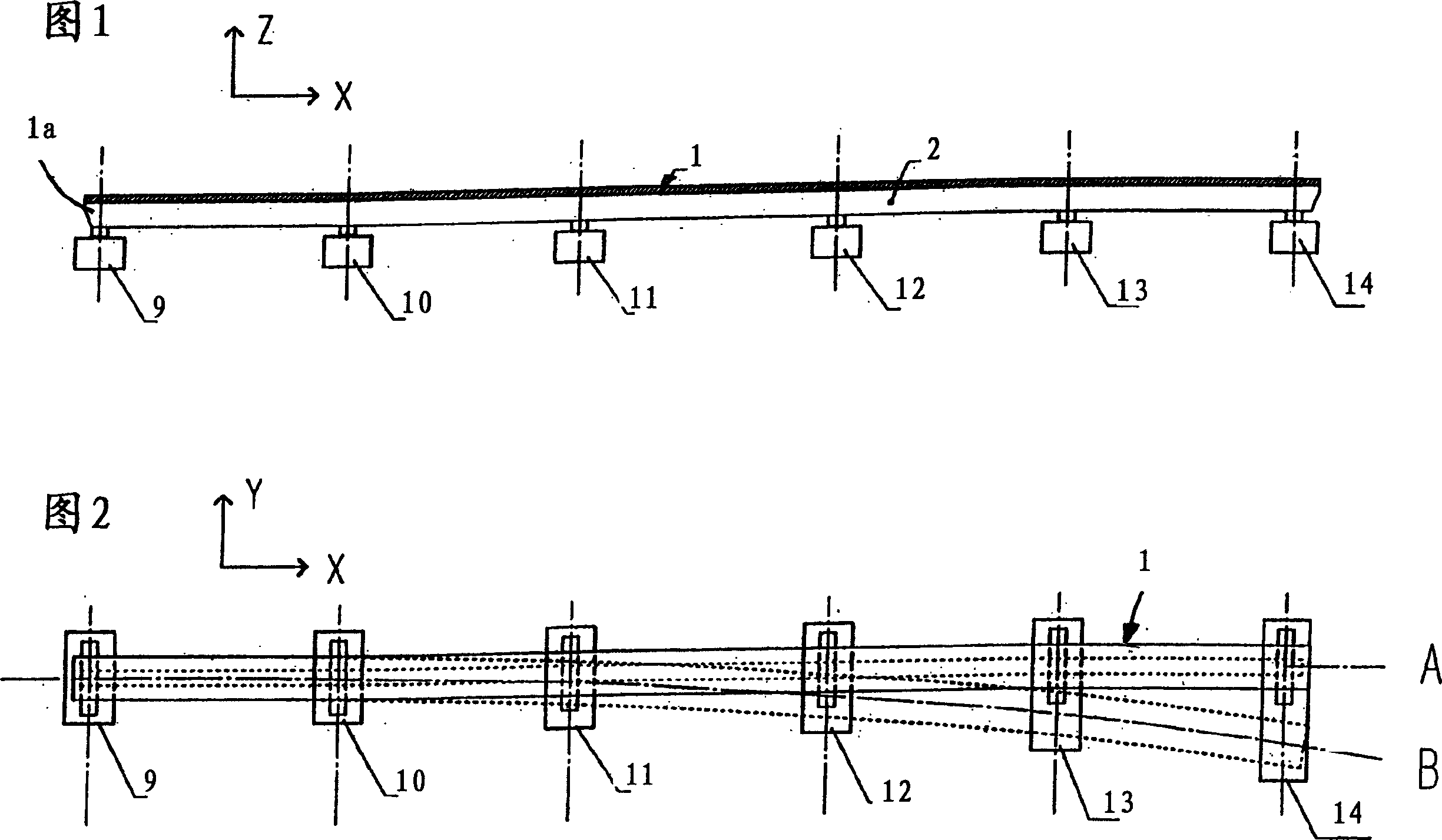

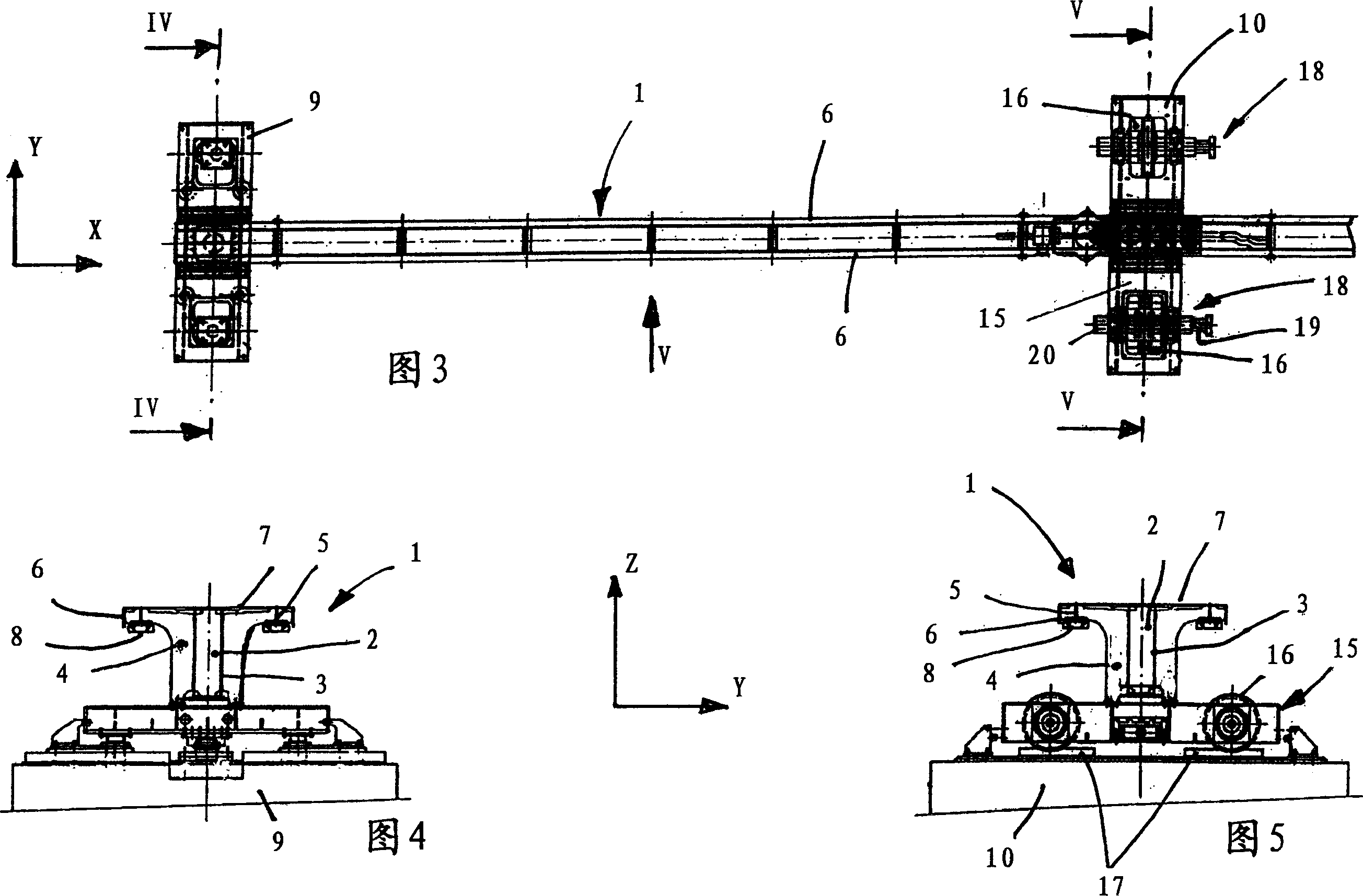

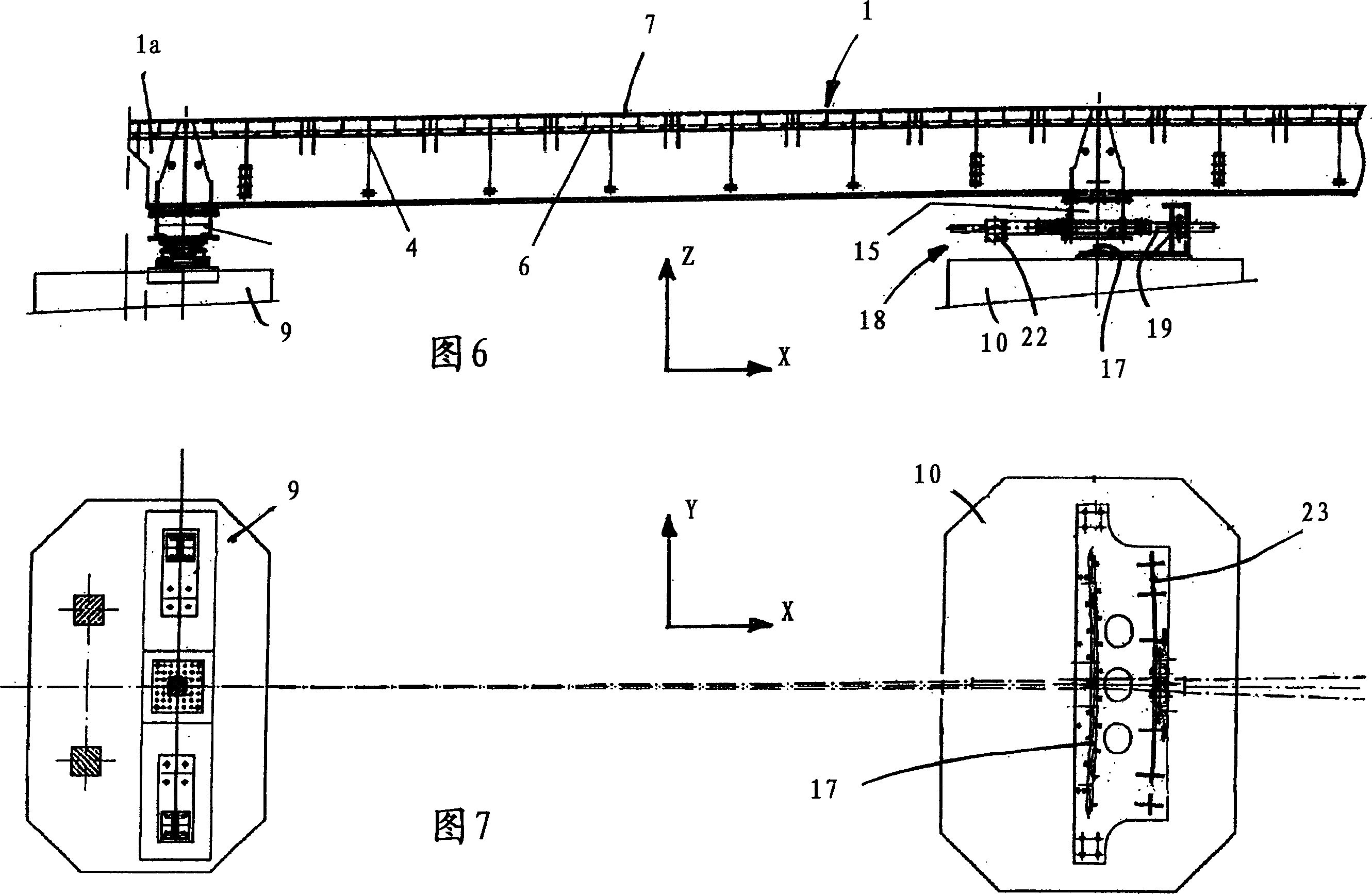

[0017] According to Figures 1 to 6, a common switch device in the form of a curve switch for a magnetic levitation vehicle comprises a bendable beam 1 made of steel and extending along the full length of the switch, which is for example about 50 m long or more long. The beam 1 comprises a support element 2 extending in the longitudinal direction (=x-direction), which preferably consists of a box-shaped profile, ie a hollow profile with a rectangular cross-section, wherein the height is greater than the width. As shown in particular in FIGS. 4 and 5 , the support element 2 comprises two webs or side parts 3 which are substantially vertical in the mounted state and arranged perpendicular to the ground. Between the side parts 3 there are transverse plates or partitions for reinforcement. On each side part 3 a bracket or support plate 4 protruding perpendicularly therefrom is fastened, at each end of which a slat 5 extending parallel to the respective side part 3 and arranged ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com