Method and device for optimising operating parameters on an operating point of a textile machine producing cross-wound spools

A technology of operating parameters and cross-winding, which is applied in the direction of transportation and packaging, conveying filamentous materials, thin material processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

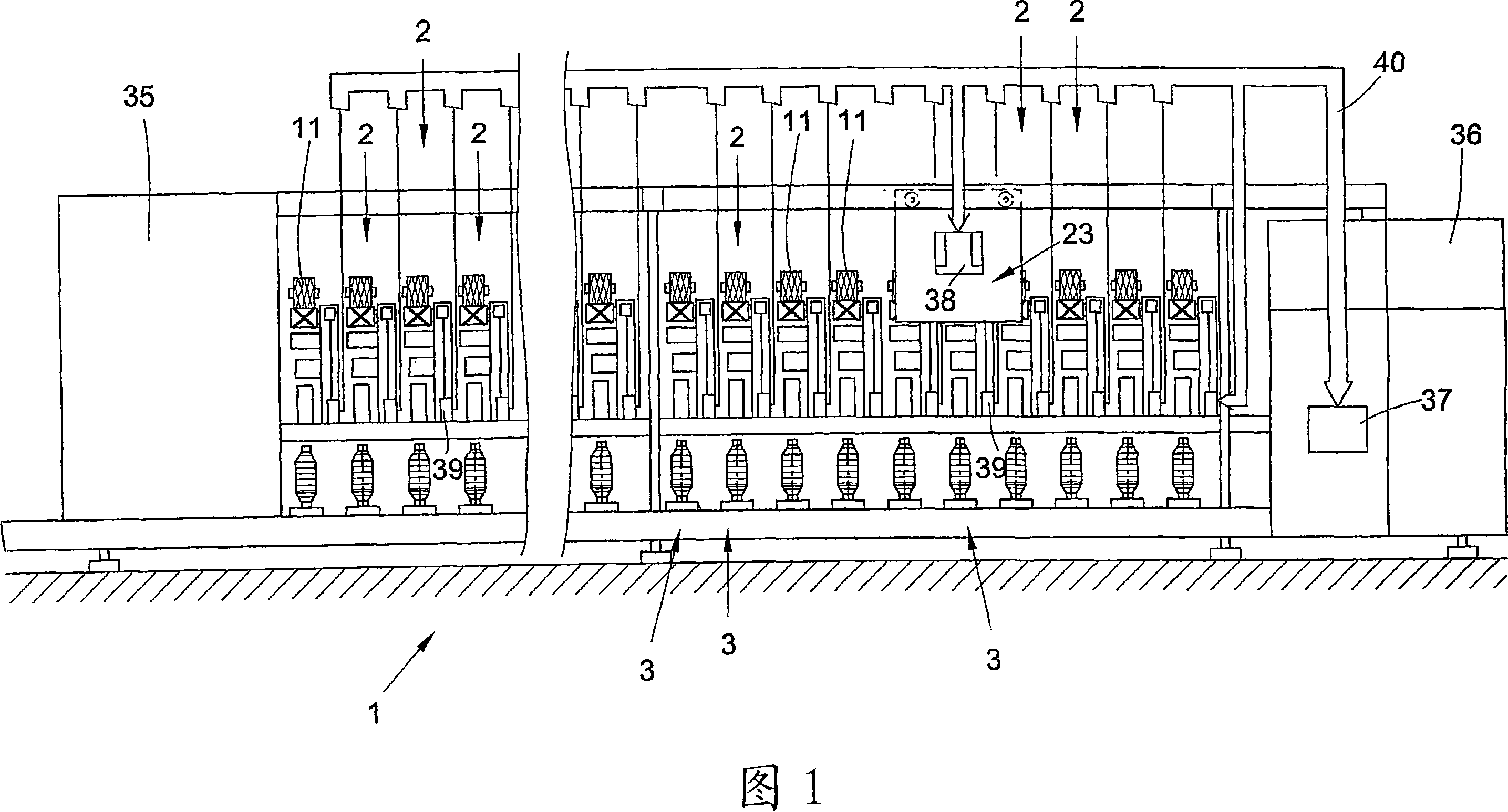

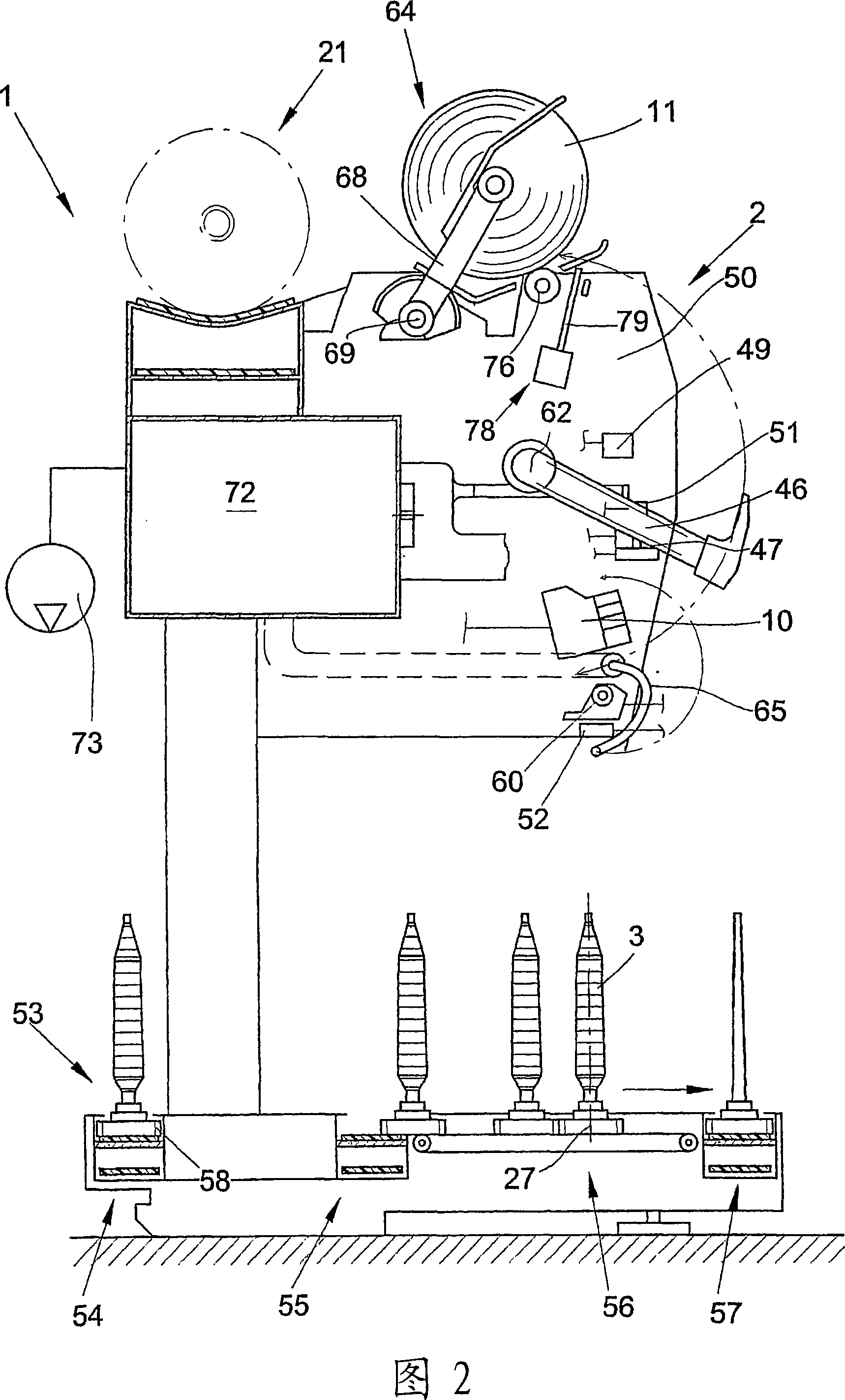

[0043] Fig. 1 schematically shows a front view of a textile machine for the production of cross-wound bobbins, indicated as a whole by the reference numeral 1, in this embodiment an automatic cross-winder. The automatic crosswinder 1 has a plurality of work stations, so-called winding heads 2 , between its end frames 35 , 36 .

[0044] Small-capacity spinning bobbins 3 produced on ring spinning machines upstream of the production process are rewound on winder 2 to form cross-winding bobbins 11 with several times the size of spinning bobbins 3 yarn capacity. The completed cross-wound spools 11 are transported by an automatic working service unit (for example by means of a cross-wound spool changer 23 ) to a transport mechanism 21 running behind the winding head 2 , which transports the cross-wound spools 11 to a spool loading station (not shown) or the like arranged at the end of the machine.

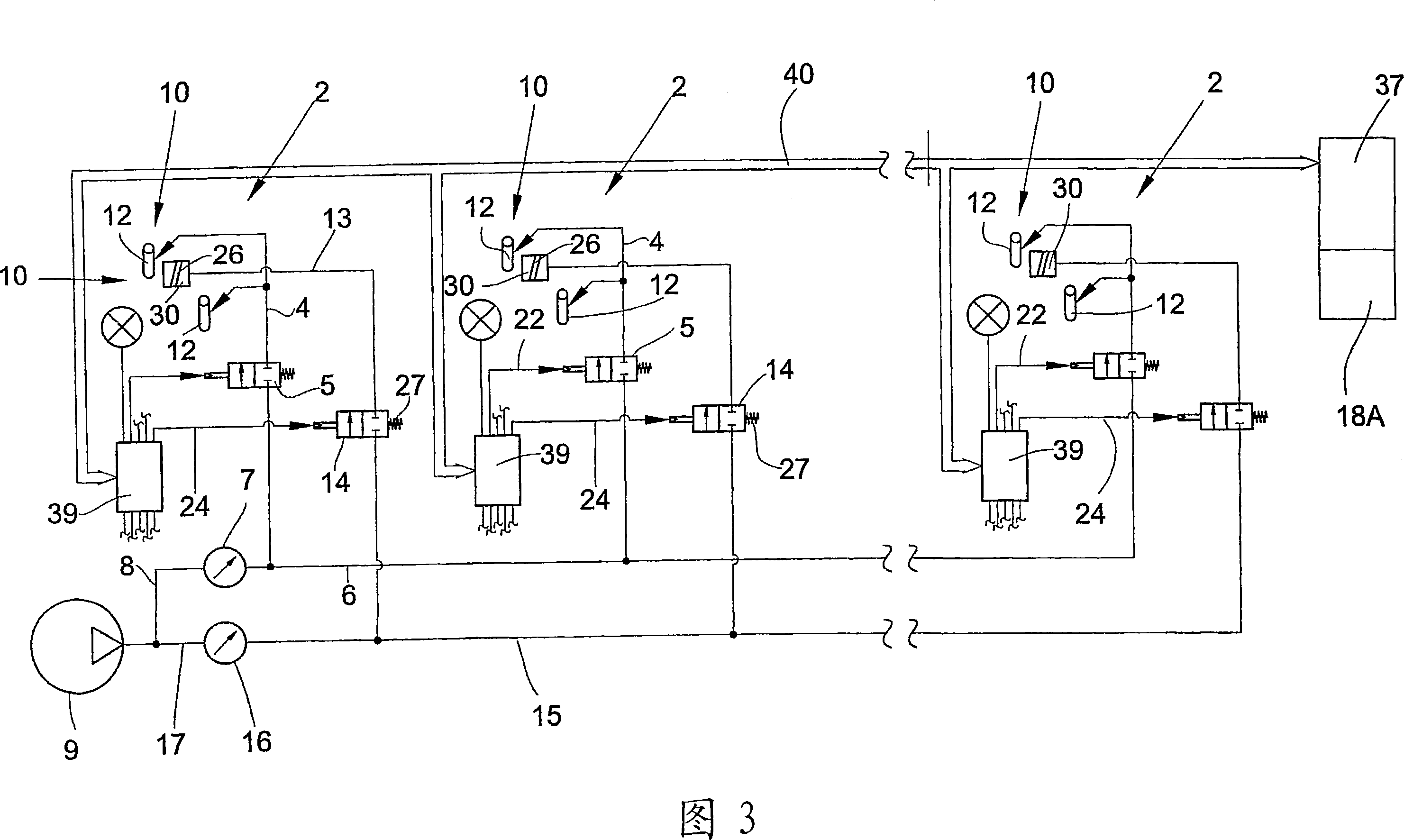

[0045] This type of automatic cross-winding machine 1 also has a central control u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com