Method for operating a power tool, especially a hand-held power tool

A hand-held machine tool, machine tool technology, applied in the direction of manufacturing tools, metal processing machinery parts, metal processing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

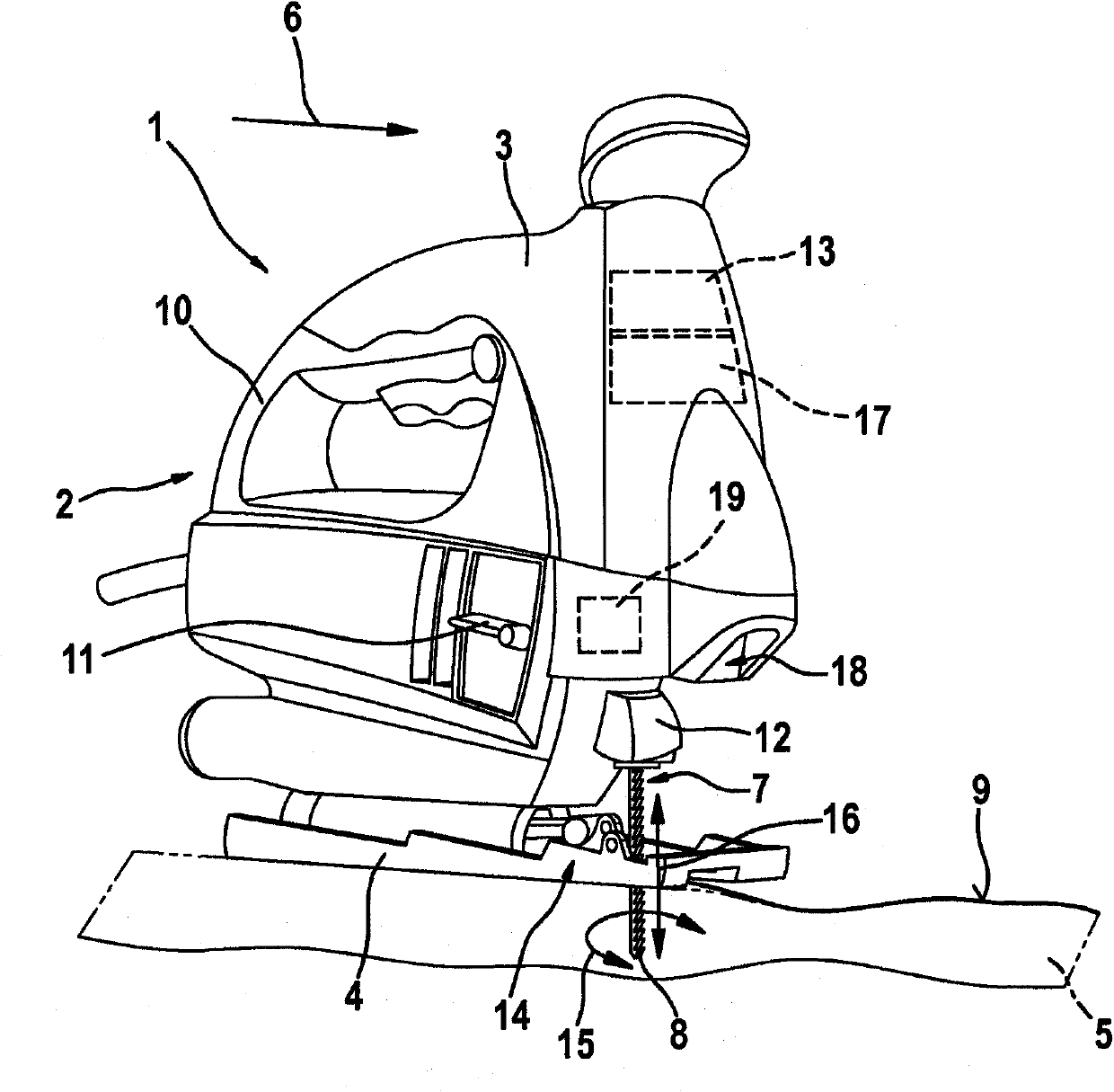

[0019] figure 1 Shown is a hand-held jigsaw 2, as an example of a power tool 1, which has in the housing 3 a saw blade 8 performing a reciprocating movement (as a working movement 7), which penetrates a base plate 4, which is in contact with the Shell 3 is connected. This base plate 4 rests on the workpiece 5 to be processed, wherein the jigsaw 2 is moved in the working direction 6 on or through the workpiece 5 . On the upper surface of the workpiece 5 , a contour line 9 represents the desired path, which serves as a marking or machining path, along which contour line 9 the saw blade 8 of the jigsaw 2 is to be guided.

[0020] The reciprocating movement of the saw blade 8 is produced by an electric drive motor housed in the housing 3 of the jigsaw 2 . On the housing 3 is located a grip 10 on which the power tool can be manually held and guided. For switching on and off, a manually operable switch is arranged in the side area of the housing 3 .

[0021] The saw blade 8 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com