Process for making an annular abrasion bead element for a cutting wire for cutting relatively hard materials

A manufacturing method and technology of annular elements, which are applied in the cutting tool manufacturing, manufacturing tools, grinding machines and other directions of sawing machine devices, can solve the problems of excessive deformation of the substrate, no cutting function, high cost and difficulty, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

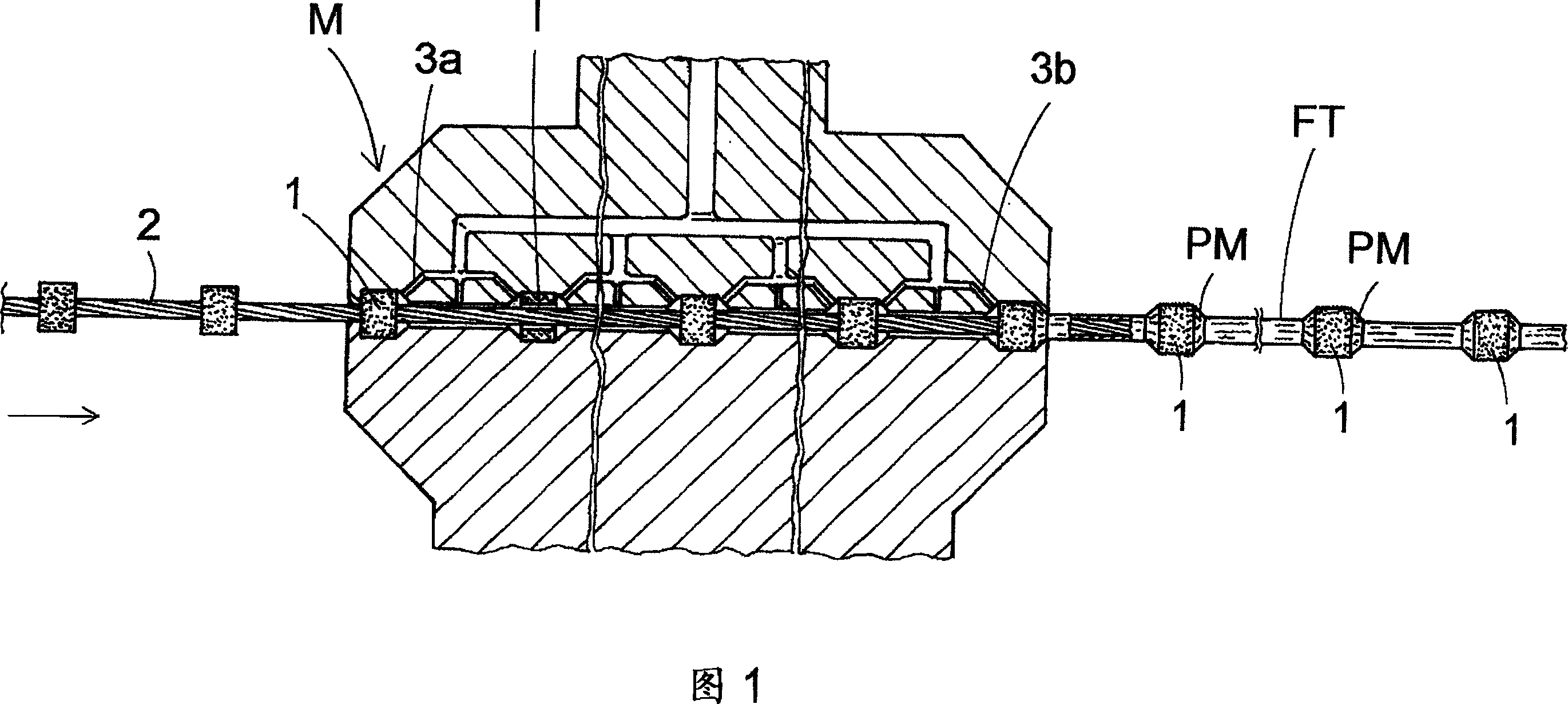

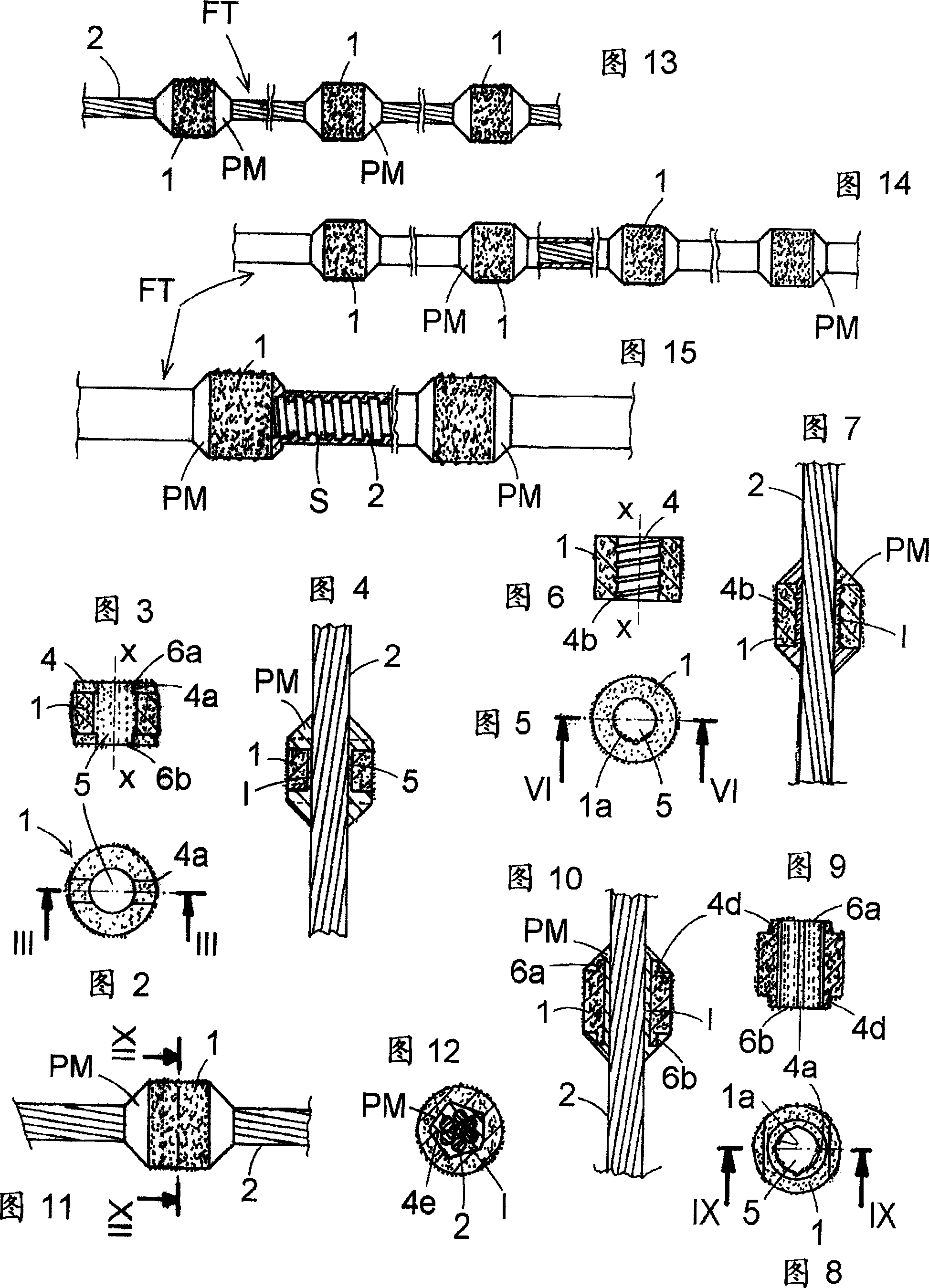

[0041] The manufacturing method of the annular grinding element or bead 1 for cutting wire according to the invention comprises the following steps in sequence:

[0042] - loading a mixture of metallic material powder and abrasive particulate material into at least one annular seat of the first mould; and

[0043] - extruding said mixture in said mould, thereby obtaining at least one annular shaped element having a through hole.

[0044] Due to the configuration of the seat of the mold such that the preformed element has an inner wall 1 a defining a preferably longitudinal through hole, a cold pressed semi-finished or preformed element, ie an annular element, is obtained.

[0045] The preformed element thus obtained is finally subjected to a sintering treatment in order to obtain the finished annular element.

[0046] Preferably, the metal powder material is in the form of a powder or a powder agglomerate. Advantageously, the extrusion is cold pressing.

[0047] The sinteri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com