Drum core bend preventing device of barrel fluffer

A technology of deflagging machine and drum core, applied in the direction of raw material separation, recycling technology, paper recycling, etc., can solve problems such as increased bending, impact on waste paper movement, equipment damage, etc., to ensure clearance, improve installation efficiency and work reliably sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

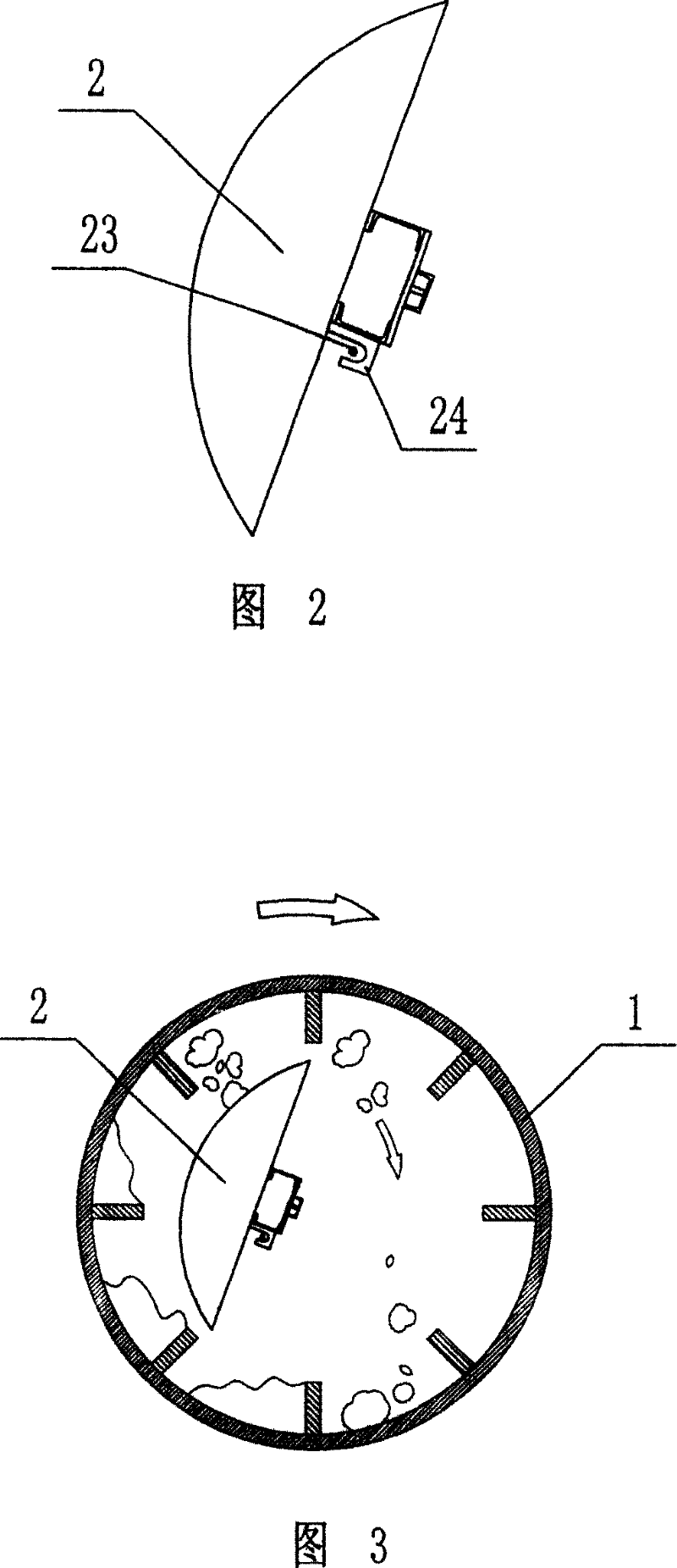

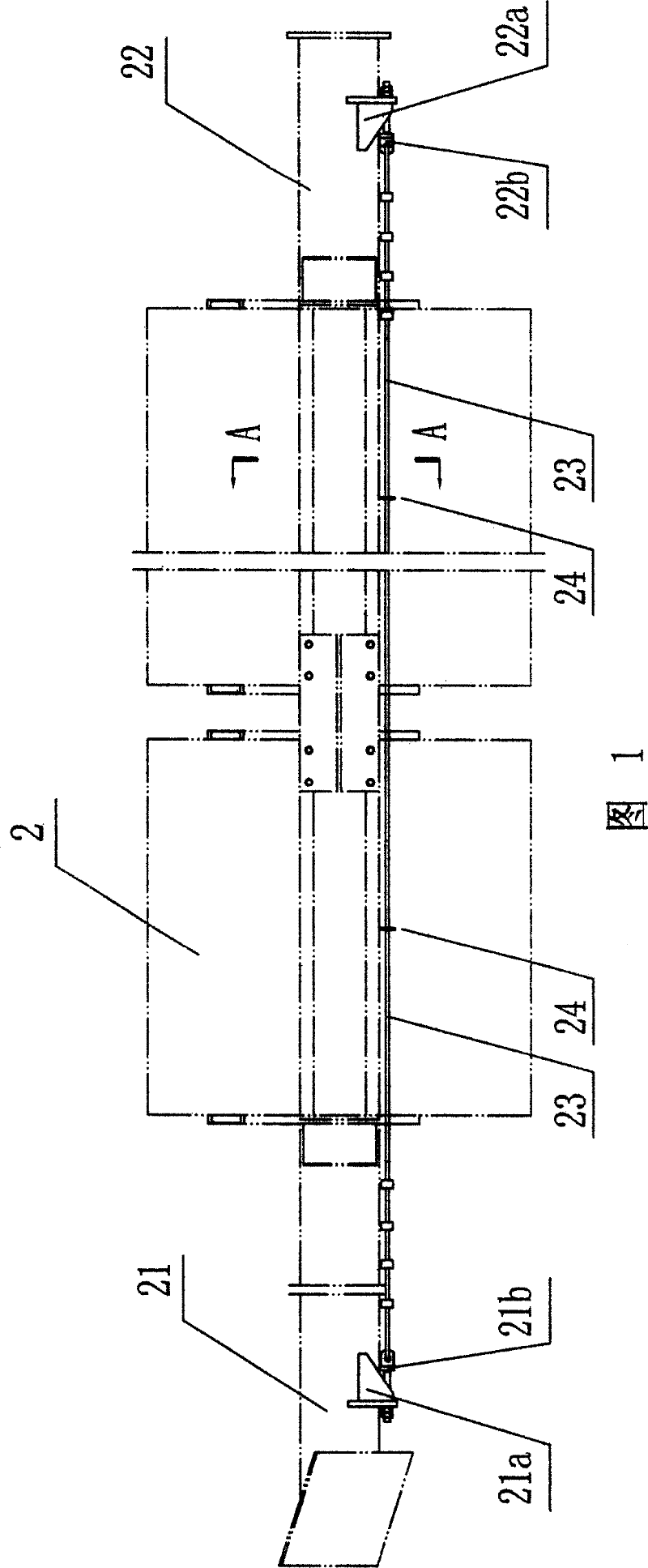

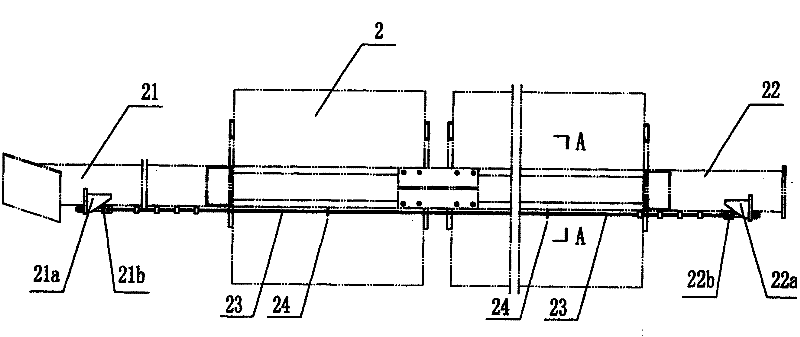

[0014] Embodiment one: if figure 1 , figure 2 , as shown in Figure 3, the anti-bending device of the drum core of the drum debonding machine includes a drum core 2 fixedly installed in the cylinder 1 of the decomposing machine along the axial direction of the decomposing machine cylinder 1, and the two ends of the drum core 2 Drum core support parts 21, 22 are respectively fixed, and a drum core straightening device that makes the axis of the drum core 2 straight is arranged between the two drum core support parts 21, 22, and the drum core straightening device The axis of is located below the axis of the drum core 2 .

[0015] The drum core straightening device comprises pull rod fixing seats 21a, 22a respectively fixed on the two drum core supporting parts 21, 22, and pull rods 21b, 22b are installed on the pull rod fixing seats 21a, 22a, and the two pull rods 21b, A steel wire rope 23 is fixed between 22b, and an adjustment device for adjusting the tension of the steel wi...

Embodiment 2

[0018] Embodiment two: see figure 1 , This embodiment is basically the same as Embodiment 1, except that the wire rope 23 is replaced by a rigid rod.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com