Six-speed mechanical saloon car transmission

A mechanical, transmission technology, applied in mechanical equipment, differential transmissions, gear transmissions, etc., can solve the problems of complicated transmission control mechanism, difficult vehicle space layout, and increased development difficulty, and achieve clear gear selection and shifting. Reliable, simple and novel structure, long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

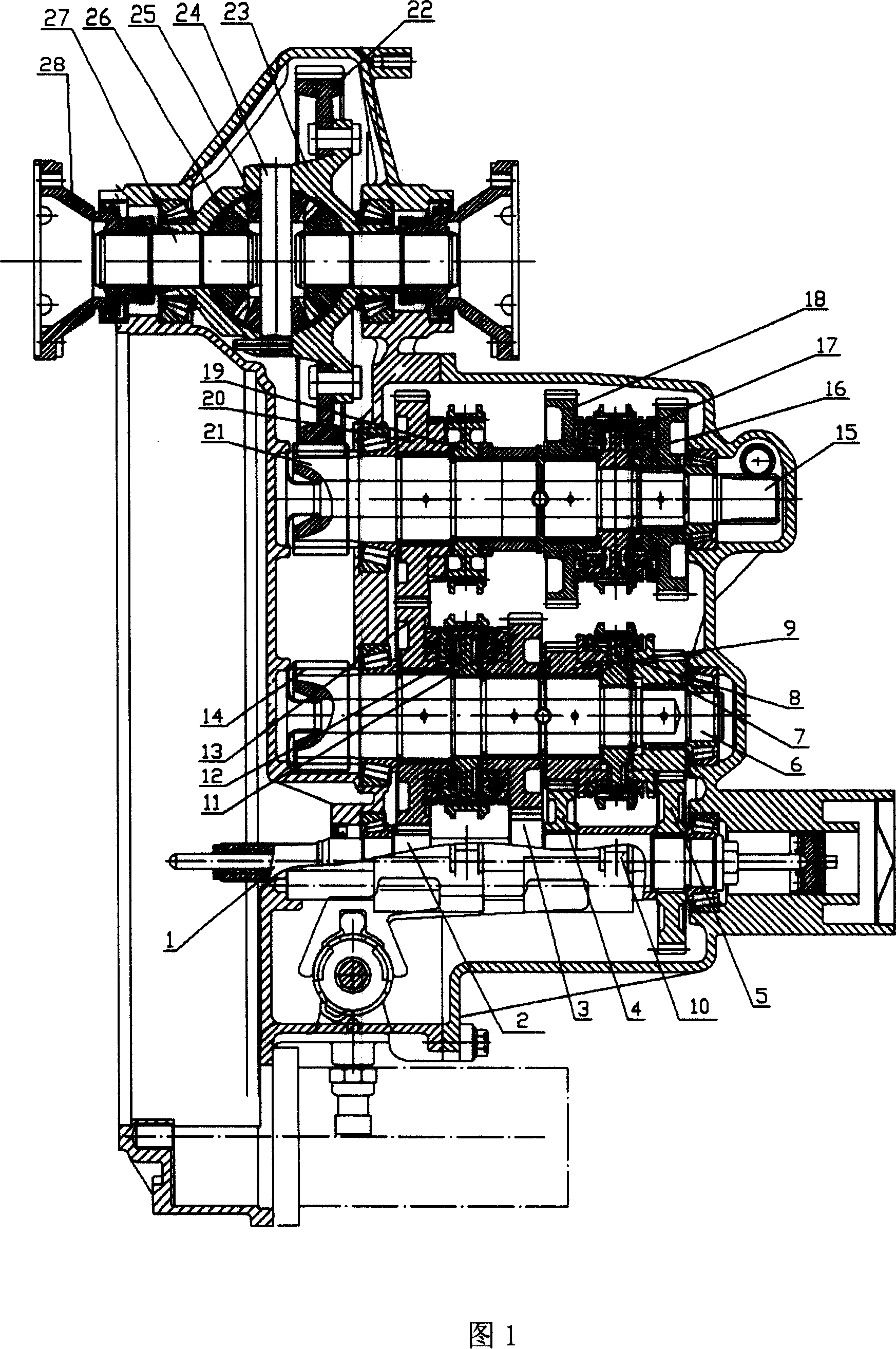

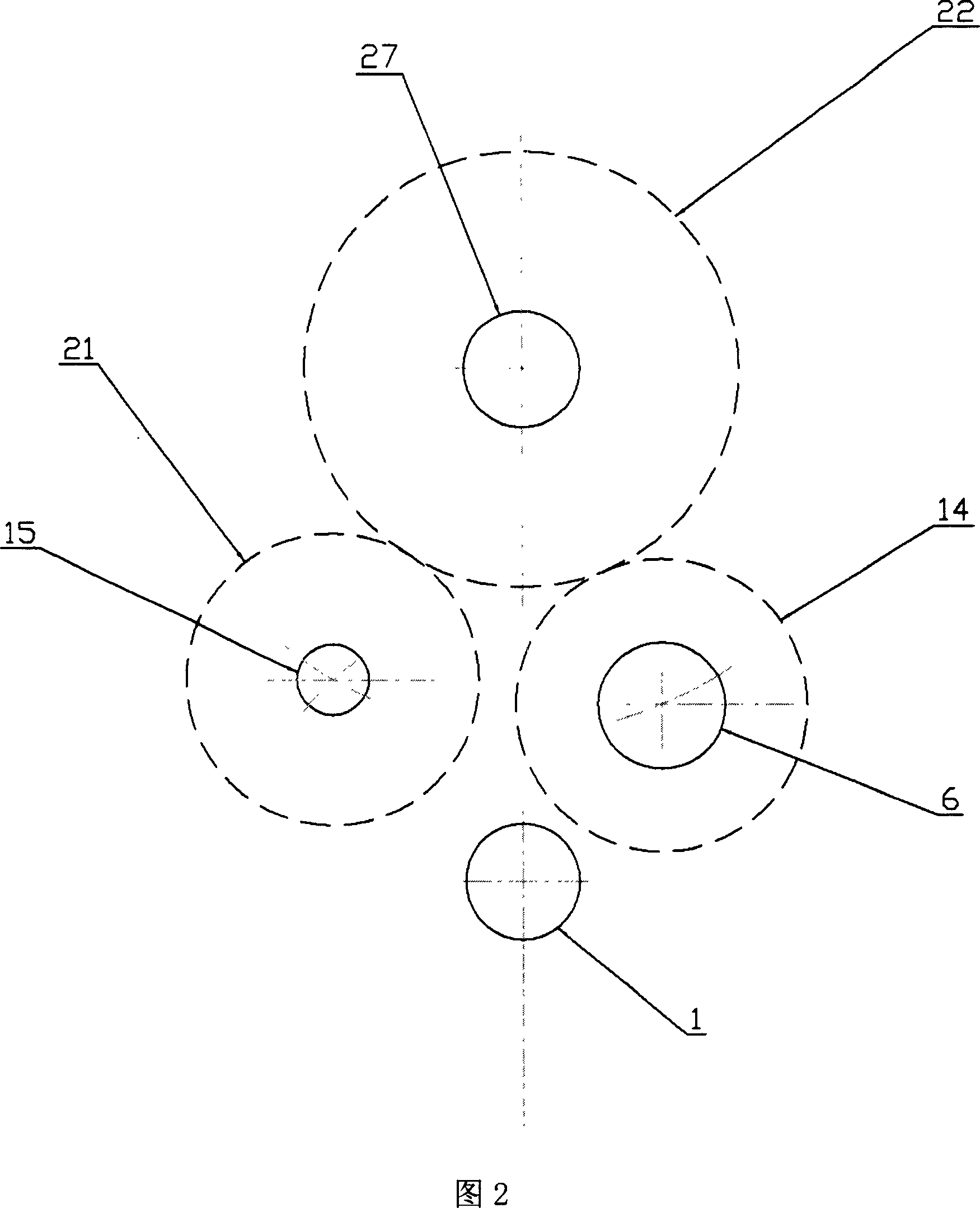

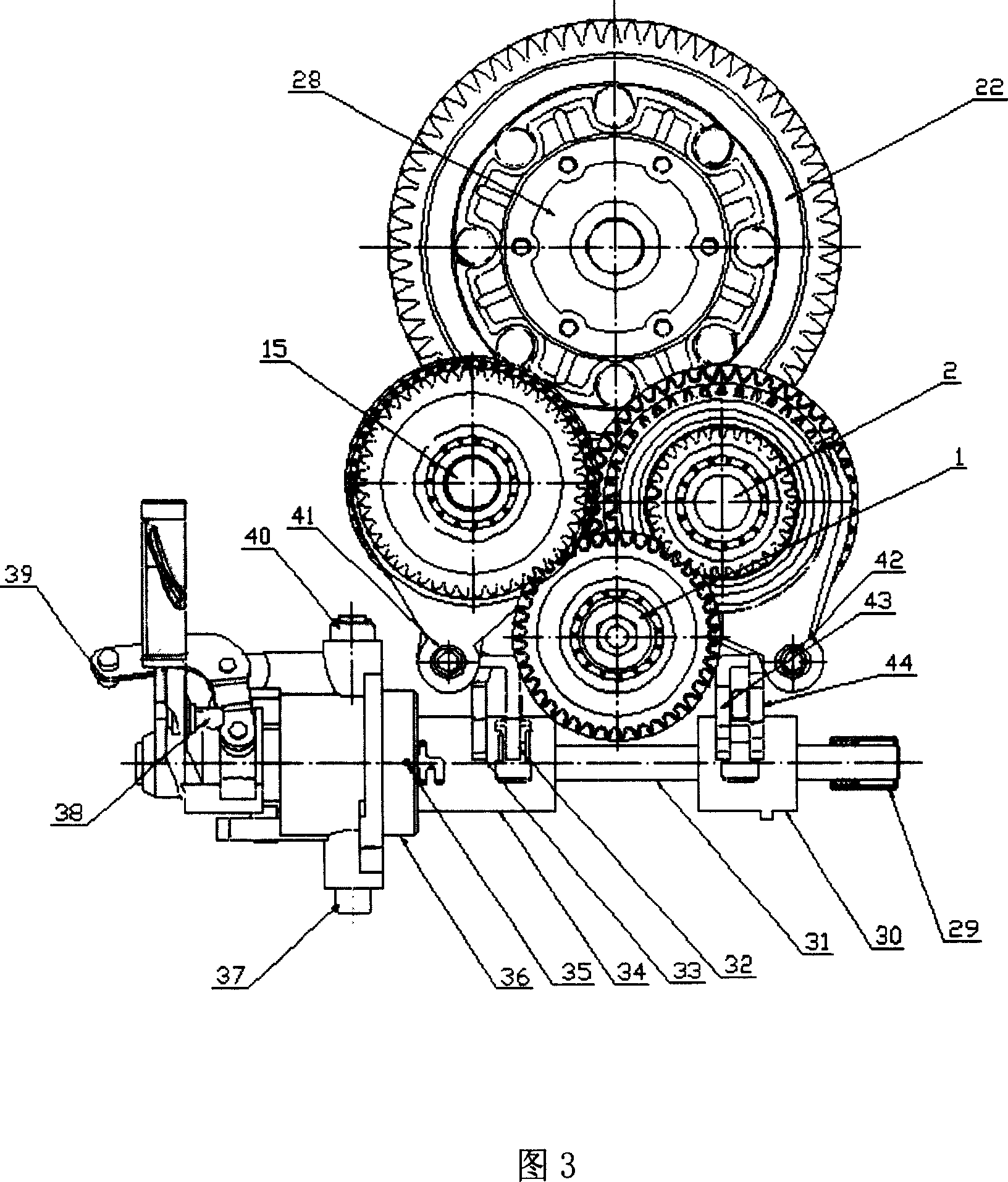

[0024] Referring to Fig. 1, the six-speed mechanical car transmission of the present invention includes an input shaft 1 connected to the engine and a gearshift control mechanism, and one, two, five and six output shafts 6, three and four are respectively arranged on one side of the input shaft 1. Reverse gear output shaft 15 and half shaft 27 (the positional relationship between each shaft is referring to Fig. 2);

[0025] On the first, second, fifth and sixth gear output shafts 6, sixth gear driven gear 7 and fifth gear driven gear 9 are installed, five and sixth gear synchronizers 8 are arranged between them, and shift fork 10 is arranged on the synchronizer 8. Also have second gear driven gear 11 simultaneously, one and two gear synchronizers 12, first gear driven gear 13, the first final reduction transmission gear 14 is all installed on the three or four reverse gear output shafts 6 of one or two, five or six gears. Third and fourth reverse gear output shaft 15 is equipp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com