Microlen array based laser beam divegence angle testing method

A technology of microlens array and testing method, which is applied in the field of optics and can solve the problems of poor real-time testing and large measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

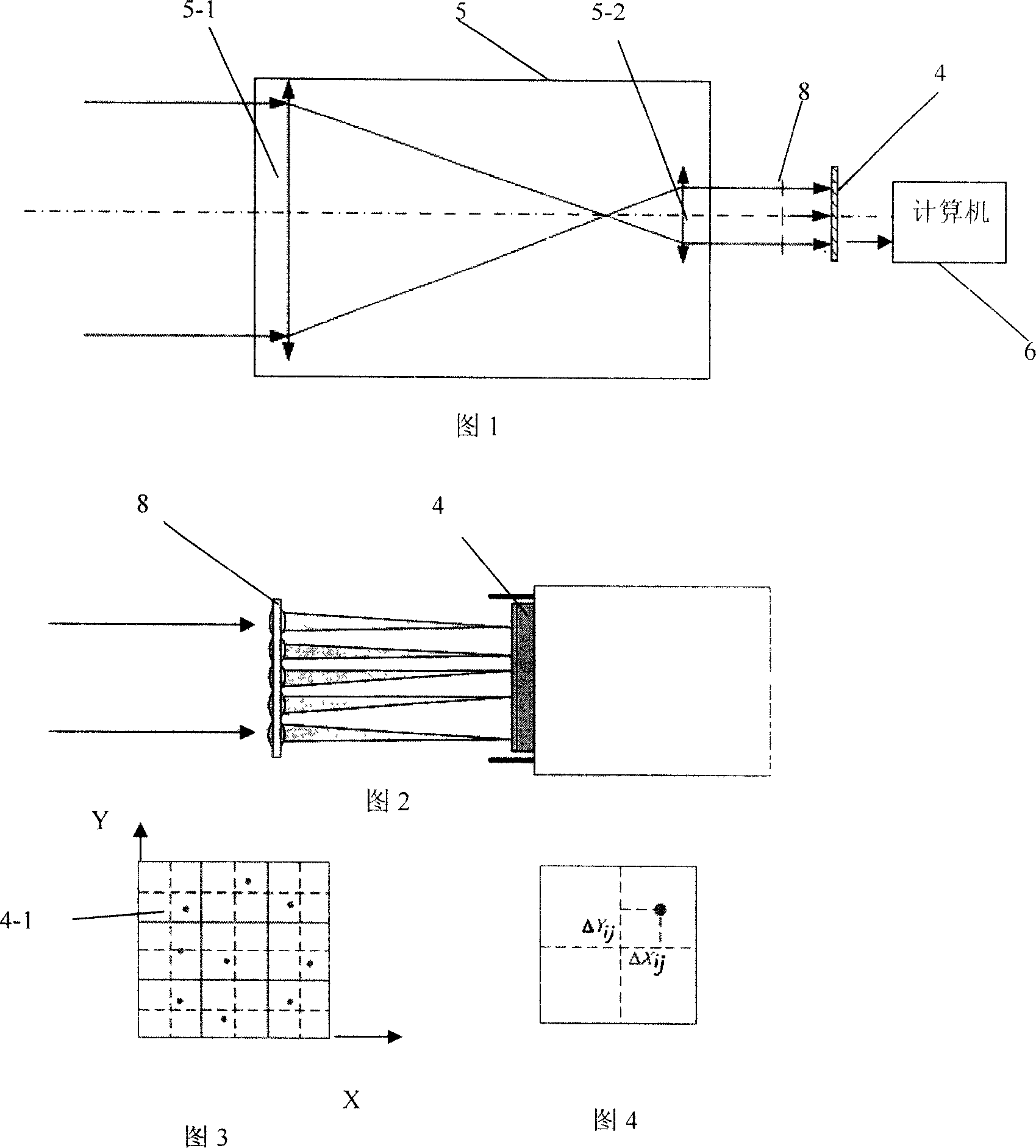

[0015] Specific Embodiment 1: The present embodiment will be specifically described below with reference to FIG. 1 to FIG. 4 . This embodiment is realized through the following steps: 1. The measured light beam is incident on the telescope system 5 made up of lens 5-1 and lens 5-2, so that the spot diameter of the output measured light beam matches the external dimensions of the microlens array 8 , the microlens array 8 includes m×n identical sub-lenses 8-3 arranged in a matrix; two, the microlens array 8 divides the light spot of the measured light beam into m×n groups of sub-beams, and focuses the sub-beams On the focal plane, m×n sub-spots are formed; 3. Use the area array CCD detector 4 to detect the sub-spots, the photosensitive surface of the area array CCD detector 4 is divided into m×n sub-detection areas 4-1, each sub-spot The optical axis of the lens 8-3 passes through the center point of a sub-detection area 4-1; when the sub-beam transmission direction is parallel ...

specific Embodiment approach 2

[0024] Specific Embodiment 2: The present embodiment will be specifically described below with reference to FIG. 1 . The difference between this embodiment and Embodiment 1 is that the telescope system 5 adopts a transmission telescope with an aperture of 300 mm and a magnification of 50. It can compress the spot diameter of the measured beam by 50 times. Other steps are the same as the first embodiment.

specific Embodiment approach 3

[0025] Specific embodiment three: the difference between this embodiment and embodiment one is: the sub-lenses 8-3 in the microlens array are arranged in a square matrix of 64×64, and the focal length of each sub-lens 8-3 is 1 mm, and the diameter is 0.1 mm . Other steps are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com