High voltage-resisting bi-directional linear force motor with low-power consumption

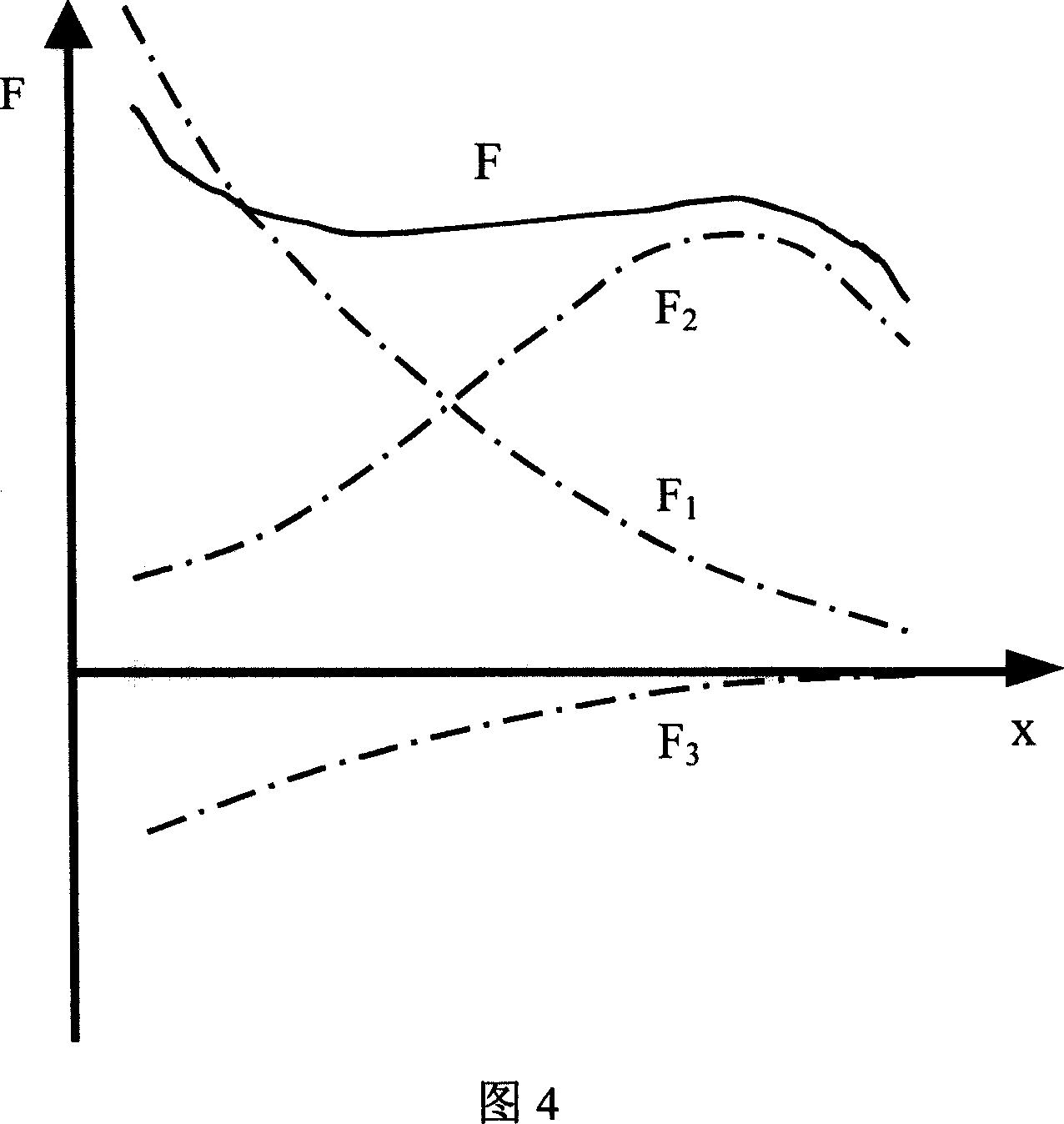

A bidirectional linear, high-voltage resistant technology, applied in the direction of electrical components, electromechanical devices, electromagnets, etc., can solve the problems that the power consumption of linear force motors cannot be effectively suppressed, and the output displacement-force characteristics of force motors are nonlinear, etc., to achieve Improved magnetic energy utilization, high power/weight ratio, and reduced non-working air gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with drawings and embodiments.

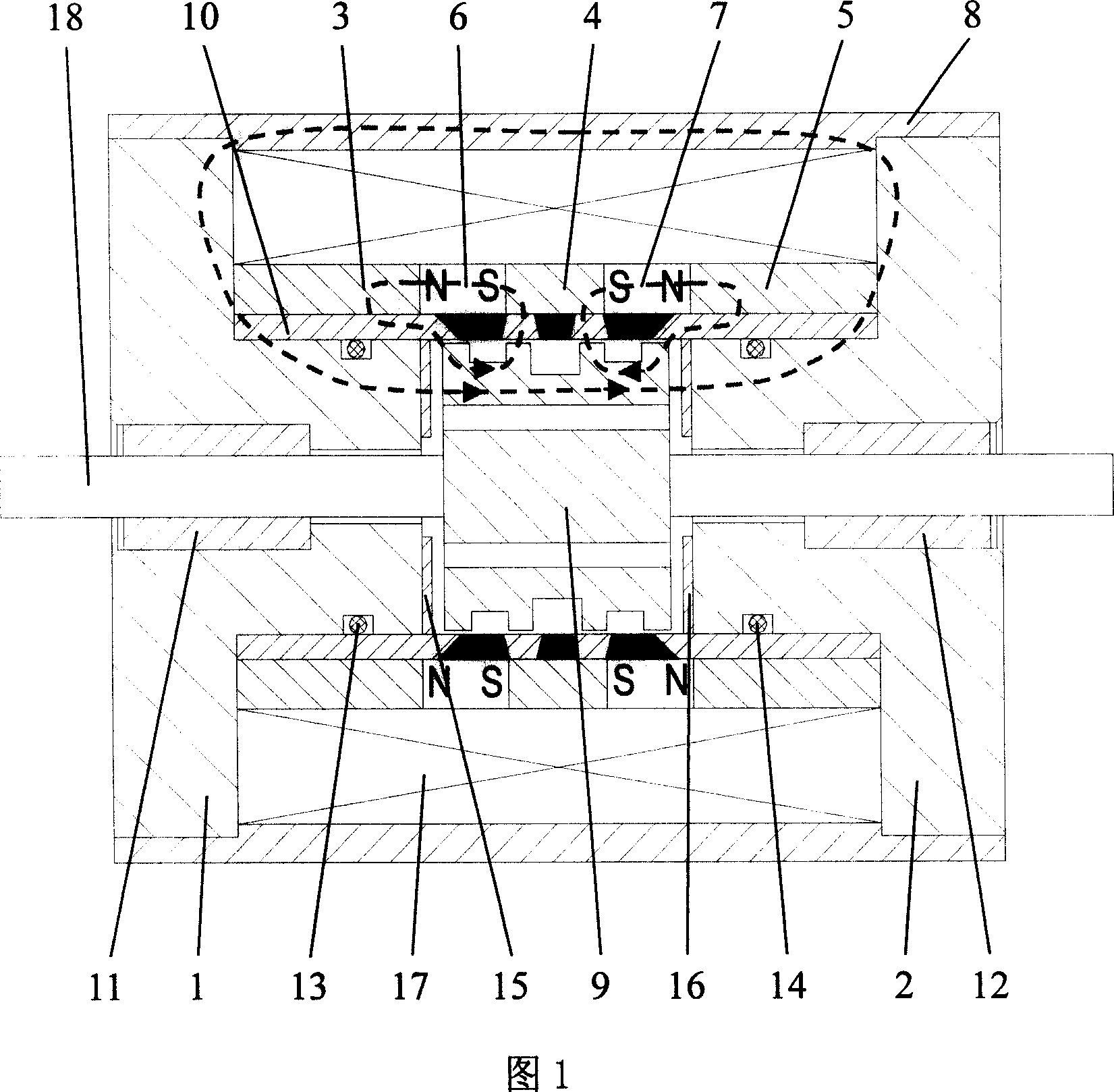

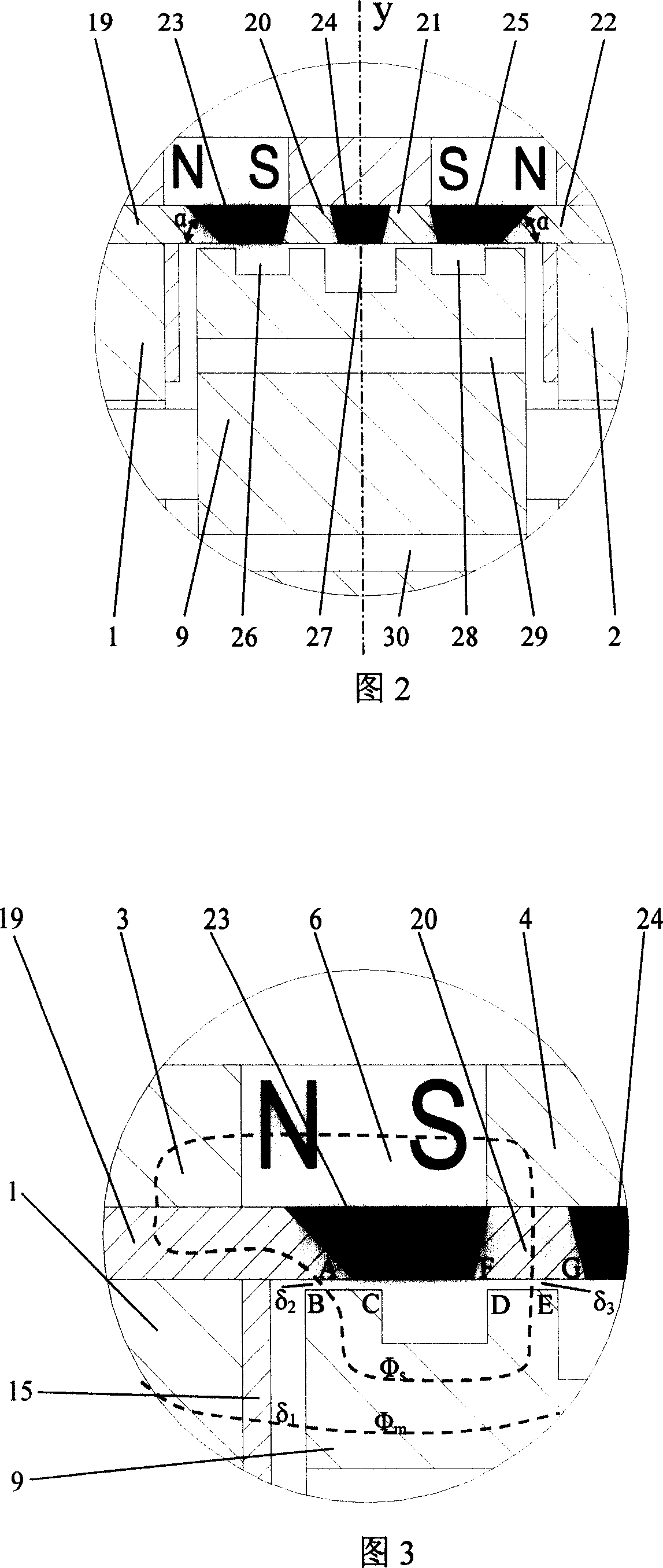

[0025] As shown in Figure 1, the present invention includes a magnetic sleeve 10, two end caps 1, 2 installed in the holes at both ends of the magnetic sleeve 10, and two end caps 1, 2 installed in the magnetic sleeve 10 and the two end caps 1, 2 holes A basin-shaped pole shoe part composed of an armature 9 with output push rods 18 at both ends; the output push rods 18 at both ends of the armature 9 are respectively supported in the end covers 1 and 2 in the form of support sleeves 11 and 12, and the armature 9 and the magnetic sleeve 10 A radial gap is formed; the inner end faces of the two end covers 1 and 2 are respectively equipped with stoppers 15 and 16 made of non-magnetic materials, and the two ends of the armature 9 form axial gaps with the stoppers 15 and 16 respectively; the armature 9 The output push rods 18 at both ends are respectively supported in the end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com