Inverted miniature relay

A relay and flip-chip technology, applied in the direction of relays, electromagnetic relays, detailed information of electromagnetic relays, etc., can solve the problems of increased manufacturing cost, economy, poor stability and reliability, insufficient elastic pressure, etc., to ensure stability and Reliability, improve the anti-drop performance, and eliminate the effect of poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

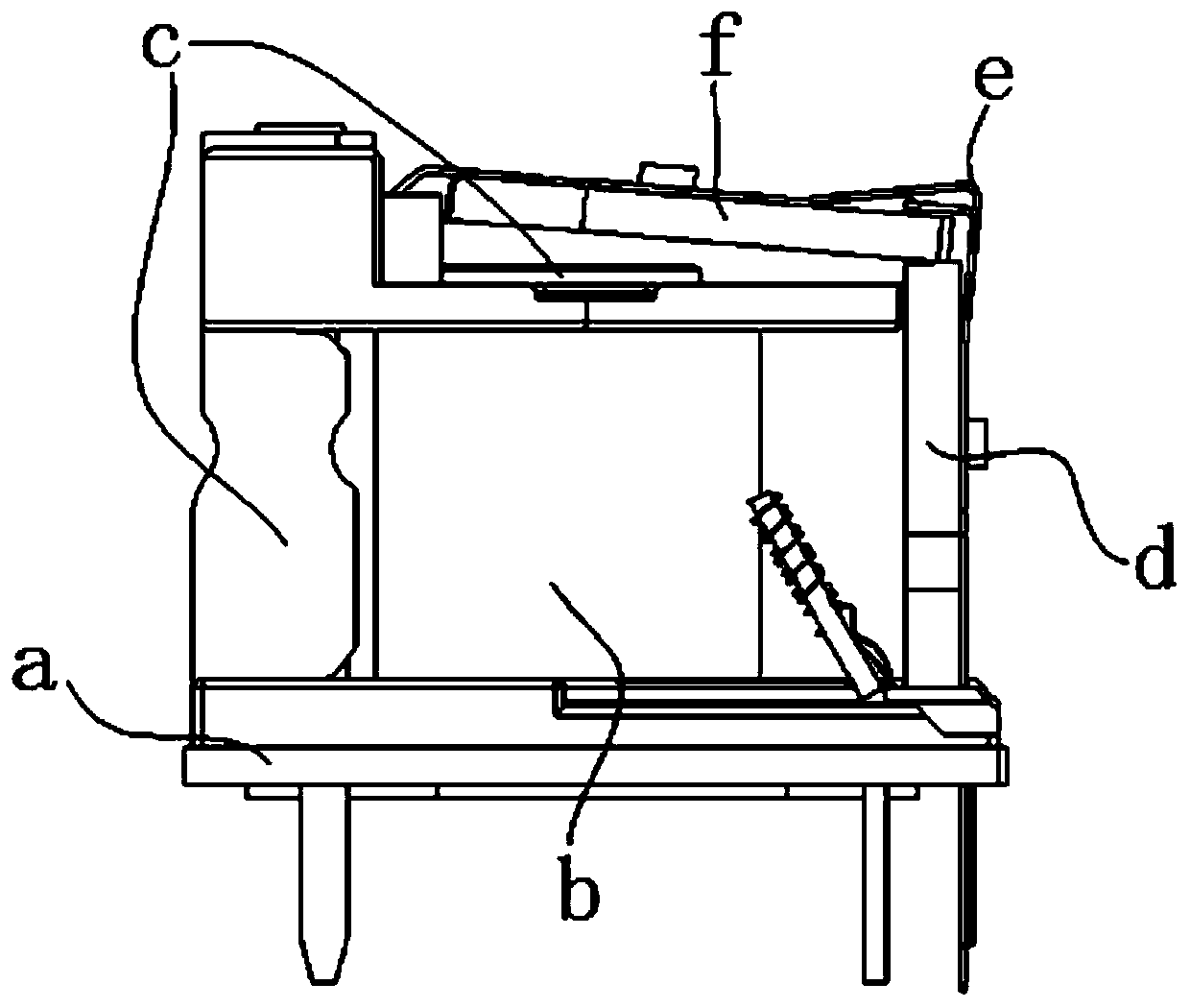

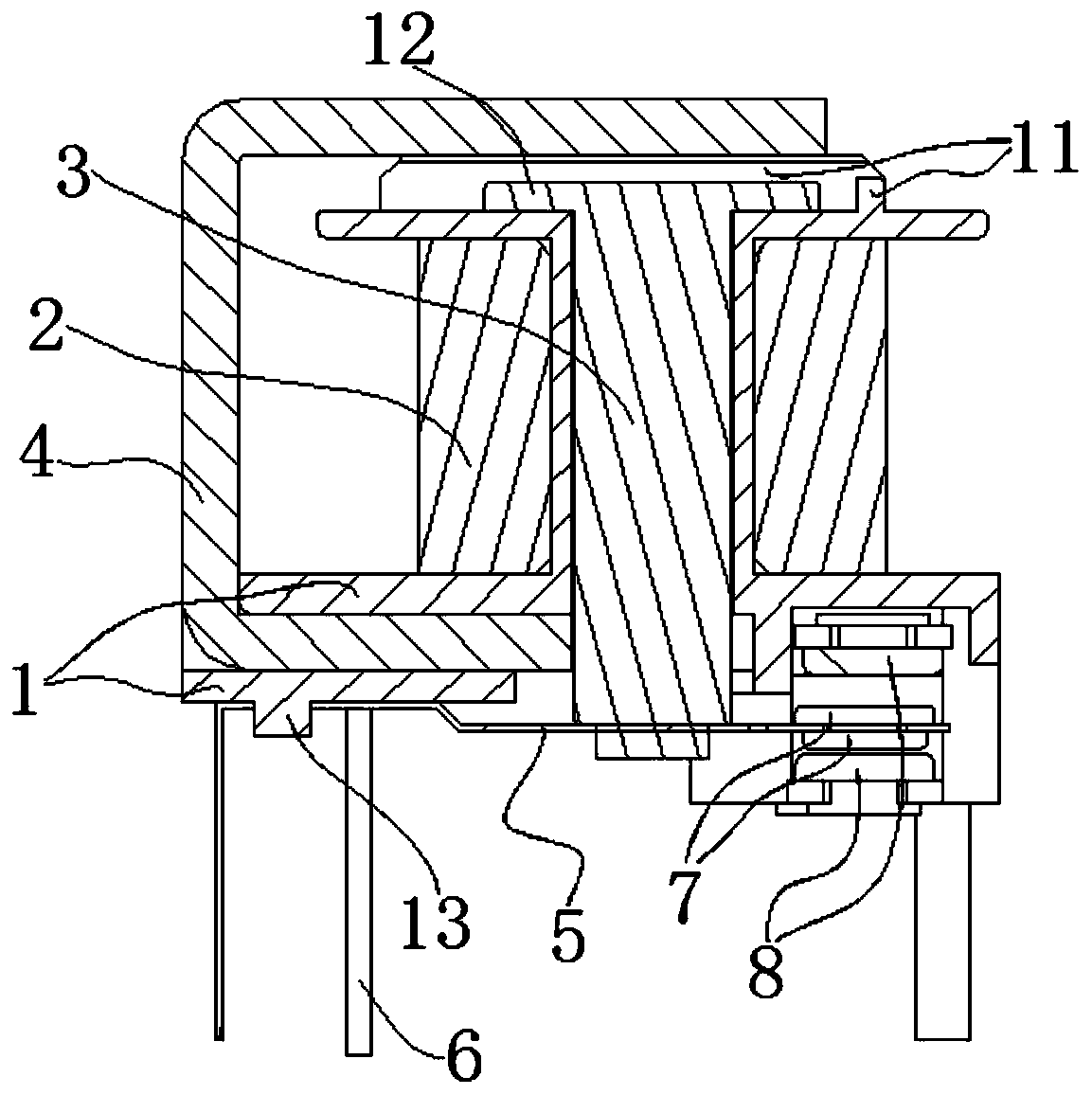

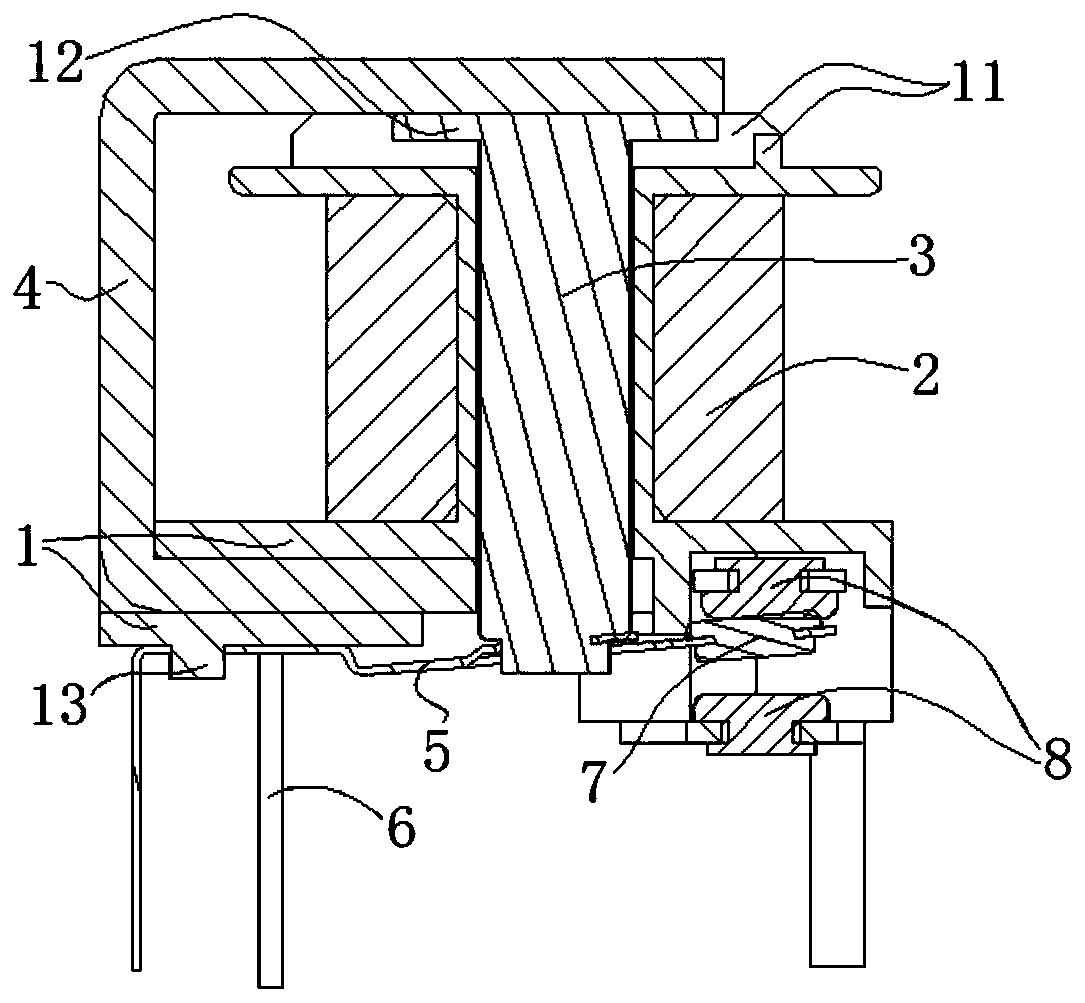

[0037] see figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, the present invention includes a bobbin 1, an iron core 3, a yoke 4, a moving spring assembly and a static spring assembly.

[0038] Among them, the coil frame 1 is a cylindrical structure with the top and bottom ends turned outward respectively, and the axial hollow of the coil frame 1 forms an iron core assembly hole. structure. A coil 2 (usually an enameled coil) is assembled in the space between the top end and the bottom end of the coil frame 1 . The bottom of the coil frame 1 is provided with a coil pin 6 connected with the coil 2 and extending outward. One side of the bottom of the bobbin 1 is provided with a radially extending insertion slot 10, the insertion slot 10 goes straight from one side of the bottom of the coil bobbin 1 to the assembly hole of the iron core, and the insertion slot 10 is a straight slot structure (specifically See figure 2 , image 3 and Figure 4 shown);...

Embodiment 2

[0047] The invention includes a coil frame, an iron core, a yoke, a moving spring assembly and a static spring assembly.

[0048] Wherein, the bobbin is a cylindrical structure whose top and bottom ends are turned outward respectively, and the axial hollow of the bobbin forms an iron core assembly hole. A coil (usually an enameled coil) is fitted in the space between the top and bottom ends of the bobbin. The bottom of the coil frame is provided with coil pins connected with the coil and extending outward. One side of the bottom of the coil frame is provided with a radially extending insertion slot, which goes straight from one side of the bottom of the coil frame to the assembly hole of the iron core, and the insertion slot is a straight slot structure; the iron core on the top of the coil frame There are three reinforcing ribs protruding upwards on the outer periphery of the assembly hole. These three reinforcing ribs enclose a space with one side opening on the top of the ...

Embodiment 3

[0057] The invention includes a coil frame, an iron core, a yoke, a moving spring assembly and a static spring assembly.

[0058]Wherein, the bobbin is a cylindrical structure whose top and bottom ends are turned outward respectively, and the axial hollow of the bobbin forms an iron core assembly hole. A coil (usually an enameled coil) is fitted in the space between the top and bottom ends of the bobbin. The bottom of the coil frame is provided with coil pins connected with the coil and extending outward. One side of the bottom of the bobbin is provided with a radially extending insertion slot, which goes straight from one side of the bottom of the bobbin to the assembly hole of the iron core, and the insertion slot is a straight slot structure. In addition, the bottom surface of the bottom of the coil frame is provided with an assembly structure of a moving spring assembly and an assembly structure of a static spring assembly.

[0059] The moving spring assembly is mainly c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com