Lift conveyor

A conveyor and lifting technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of occupying space, large structure, poor safety, etc., and achieve the effect of ensuring safety, ensuring structure, and ensuring compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

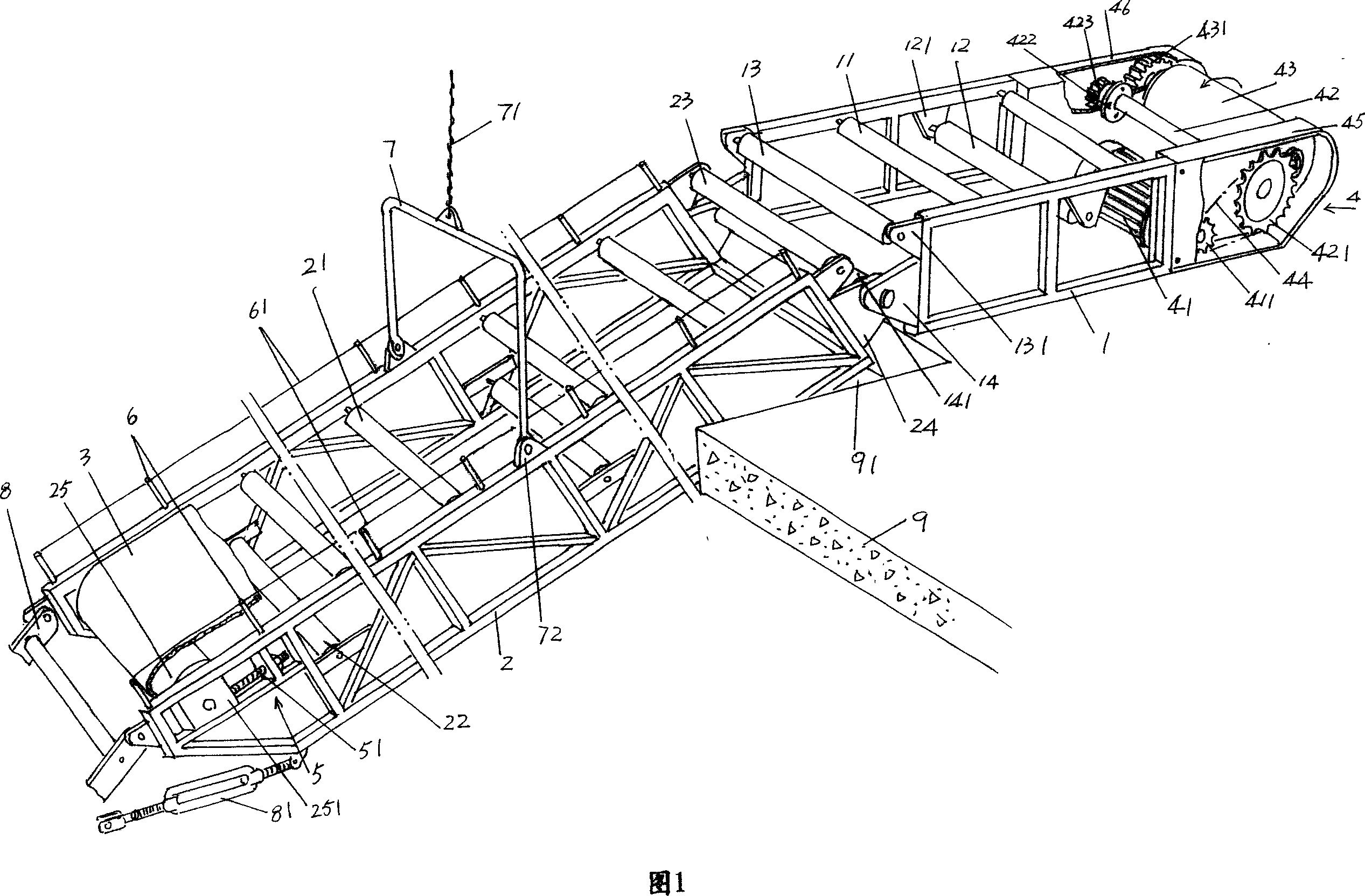

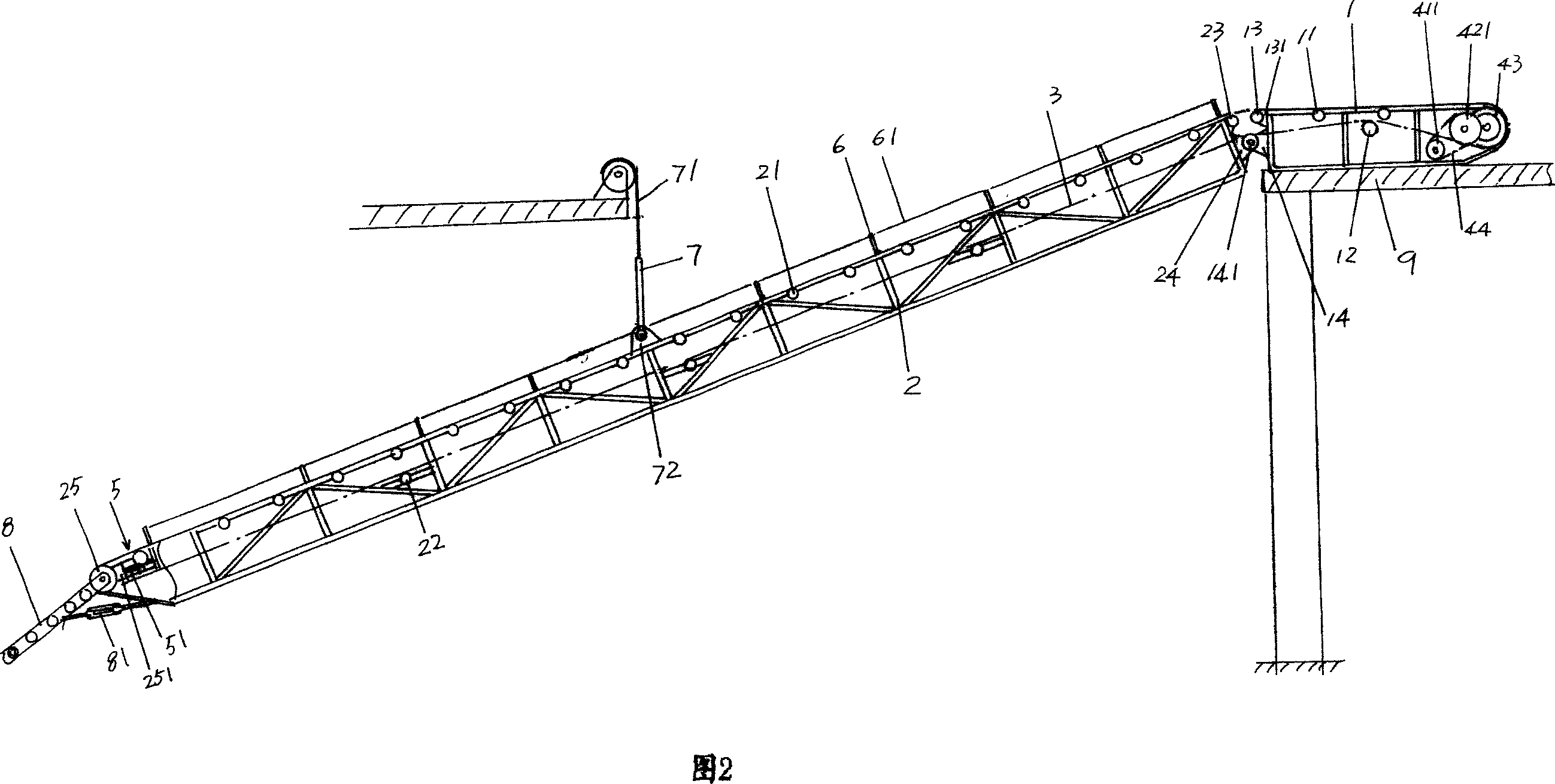

[0021] The applicant provides a more detailed description of the technical features and expected technical effects of the present invention with reference to the accompanying drawings. However, the description of all embodiments does not constitute a restriction on the technical solution of the present invention. Equivalent changes or formal or textual modifications of the technical content, especially the defined protection scope, shall be regarded as the scope covered by the patent.

[0022] In Fig. 1, the static frame 1 of the lift conveyor is provided, and the static frame 1 is usually fixedly installed on the floor of the upper floor. In order to facilitate people's better understanding, the applicant also Shown in the figure is the ground 9 of the floor, and a cavity or gap is formed on the ground 9, which is commonly referred to as opening 91 by the applicant. If the static frame 1 is fixed on the floor 91 of the fourth floor or the third floor or the second floor of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com