Contactor

A technology of contactors and static contacts, applied in the direction of relays, electromagnetic relays, detailed information of electromagnetic relays, etc., can solve problems such as unreliable wiring and large size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

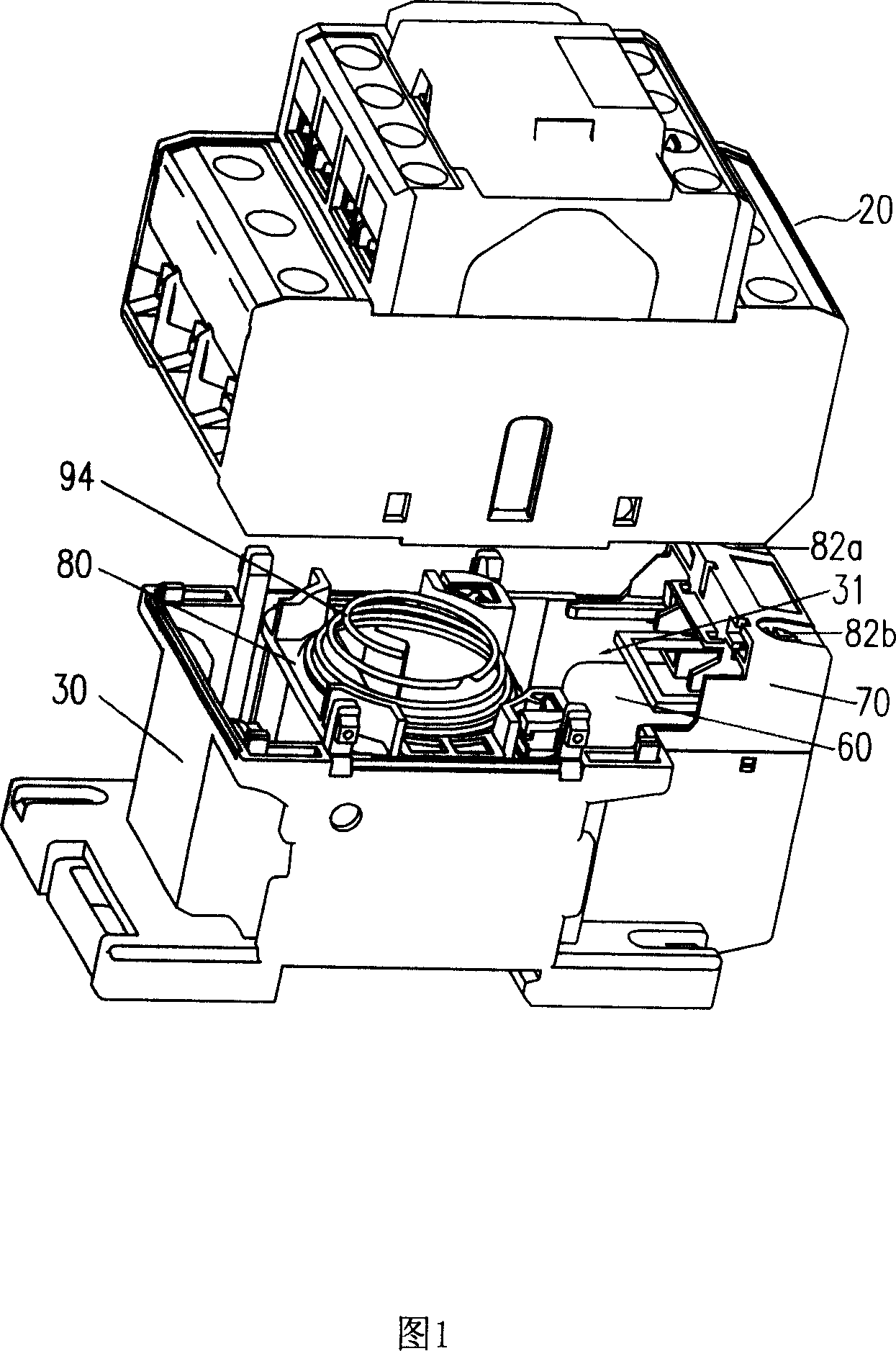

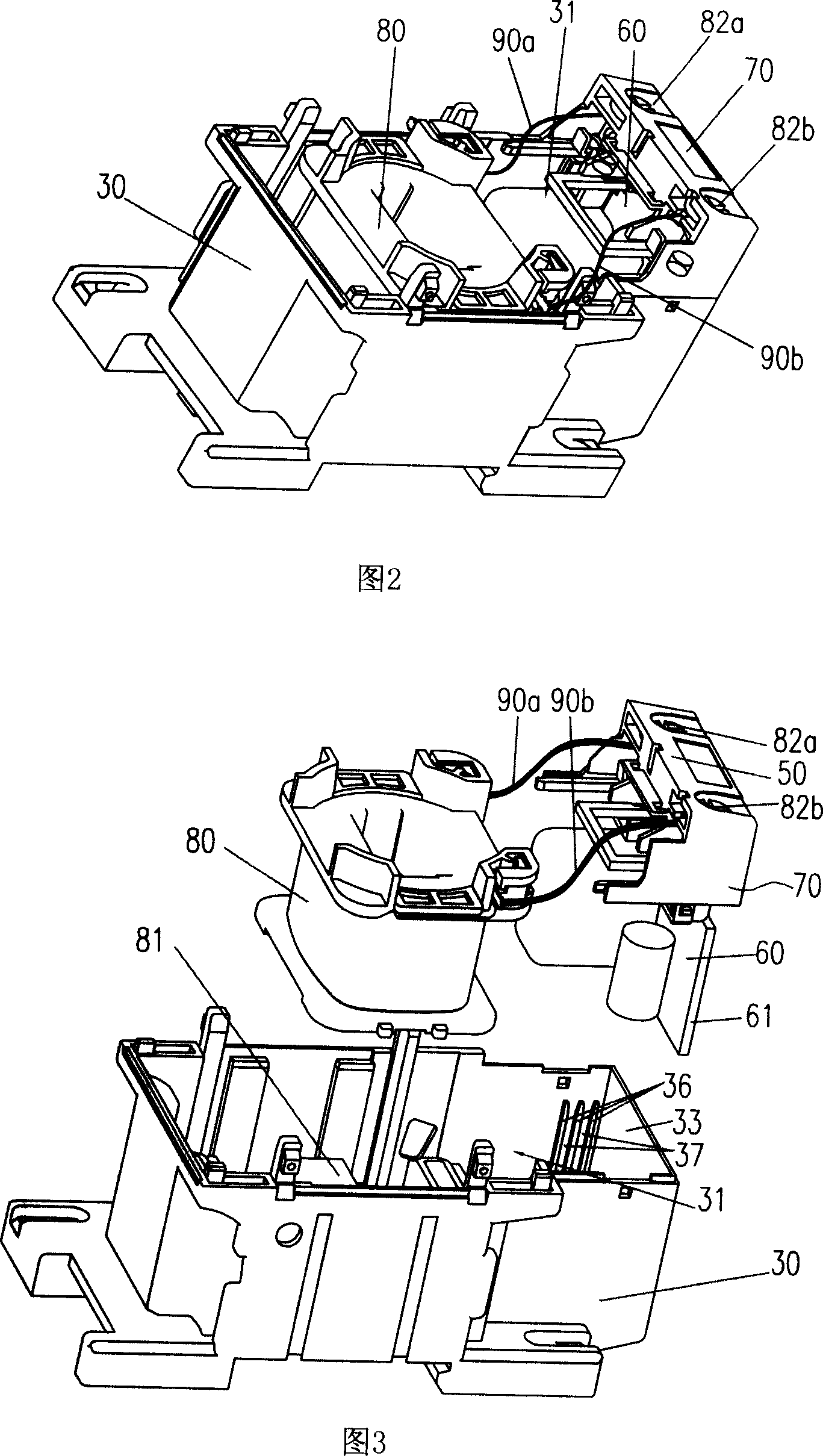

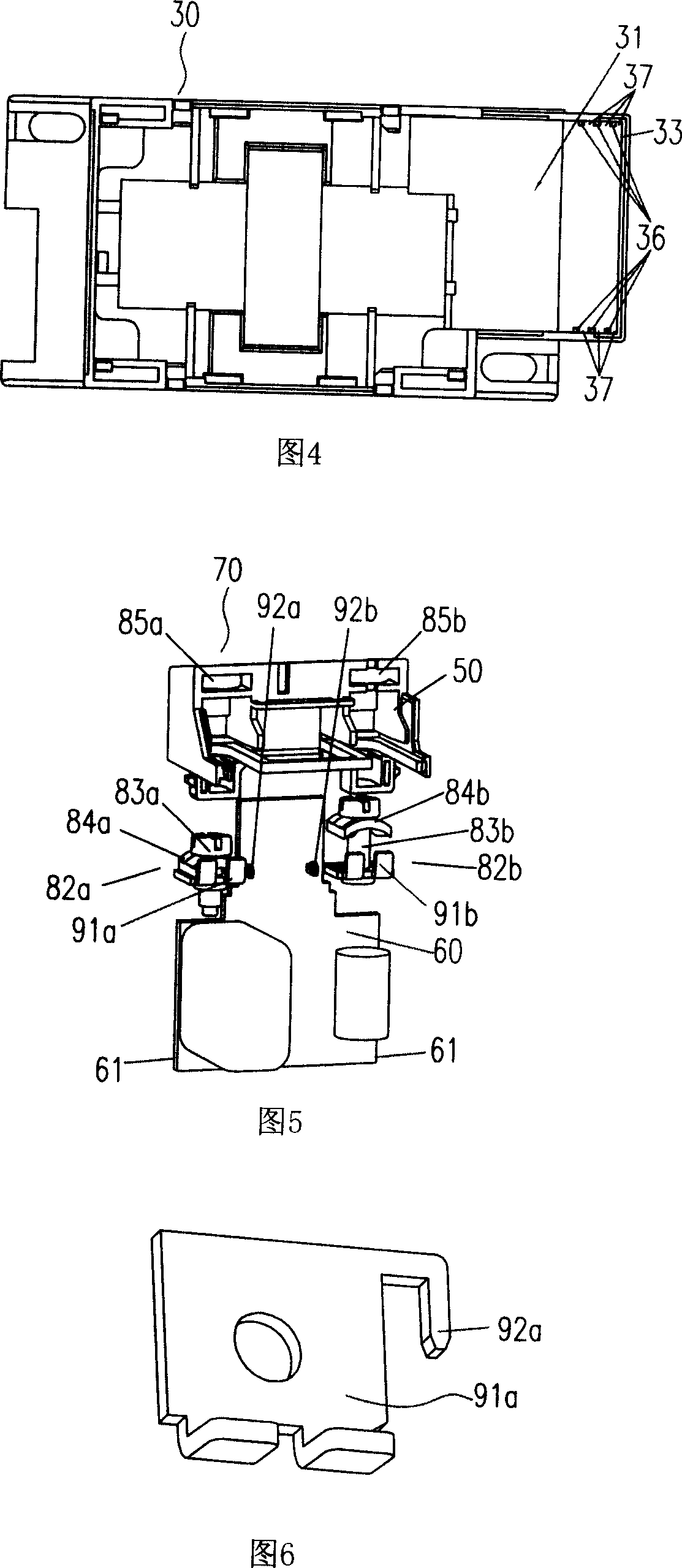

[0017] Referring to Figures 1 and 2, the contactor is provided with a base 30 and a base 20, and the base 20 is provided with a support (not shown in the figure), a return spring 94 and a static contact, and on the support A movable contact (not shown in the figure) is provided, and a coil 80, a fixed armature 81, and a pair of command terminals 82a, 82b are provided in the base 30, and a cavity 31 capable of accommodating the control circuit board 60 is also provided. When the voltage of the coil 80 rises to a certain value, a suction force is generated between the fixed armature 81 and the movable iron core to move the supporting member downward. Under the action of tension of the return spring 94, the iron core drives the supporting member to reset.

[0018] As shown in FIG. 3 , an exploded view of the base assembly, the edge 61 of the control circuit board 60 is inserted into the positioning groove 37 , thereby restricting the movement of the control circuit board in a dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com