High-strength part and process for producing the same

A manufacturing method and high-strength technology, applied in the field of components, can solve the problems of unfavorable economy, complex mold structure, and inability to deny hydrogen embrittlement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

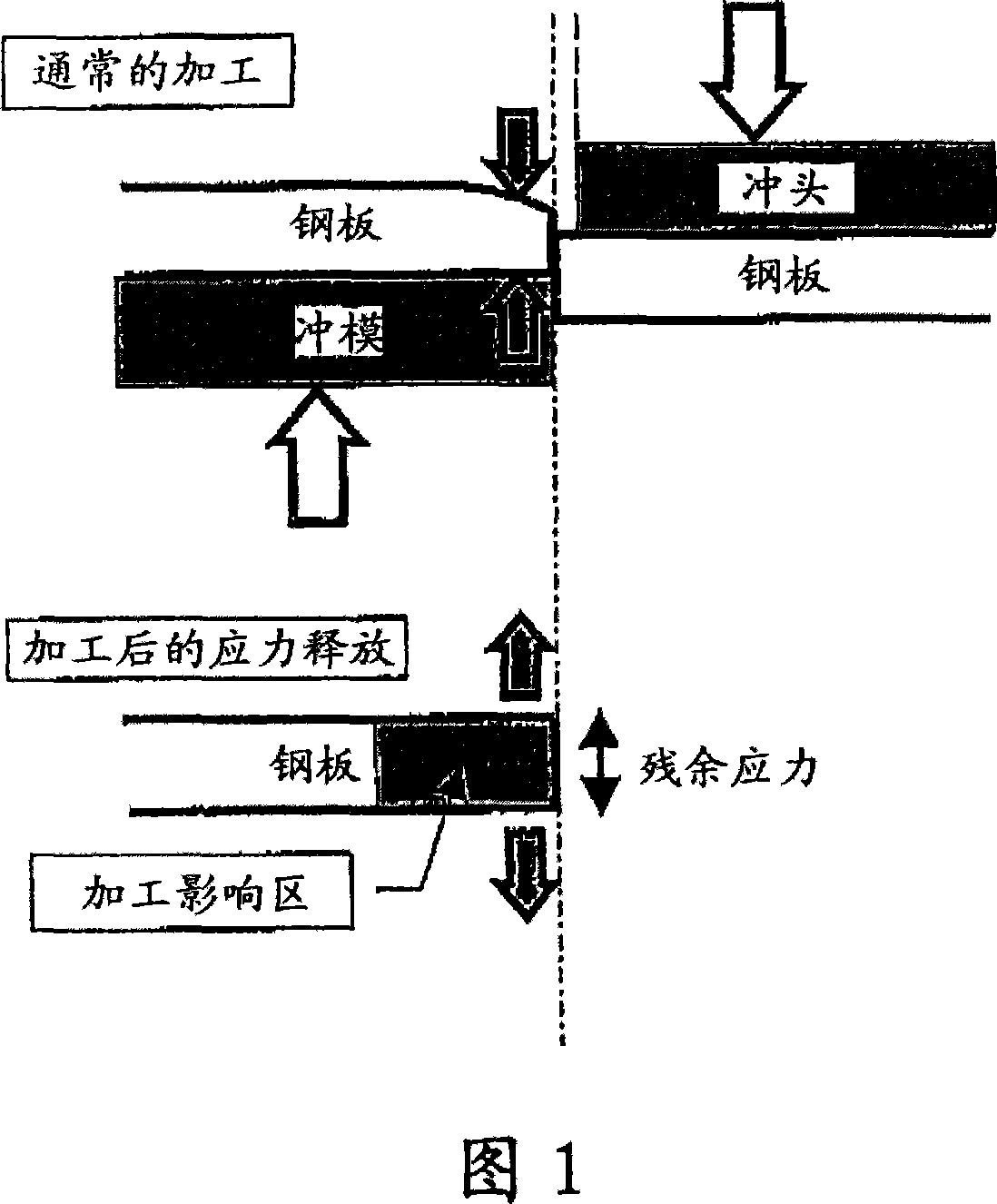

Problems solved by technology

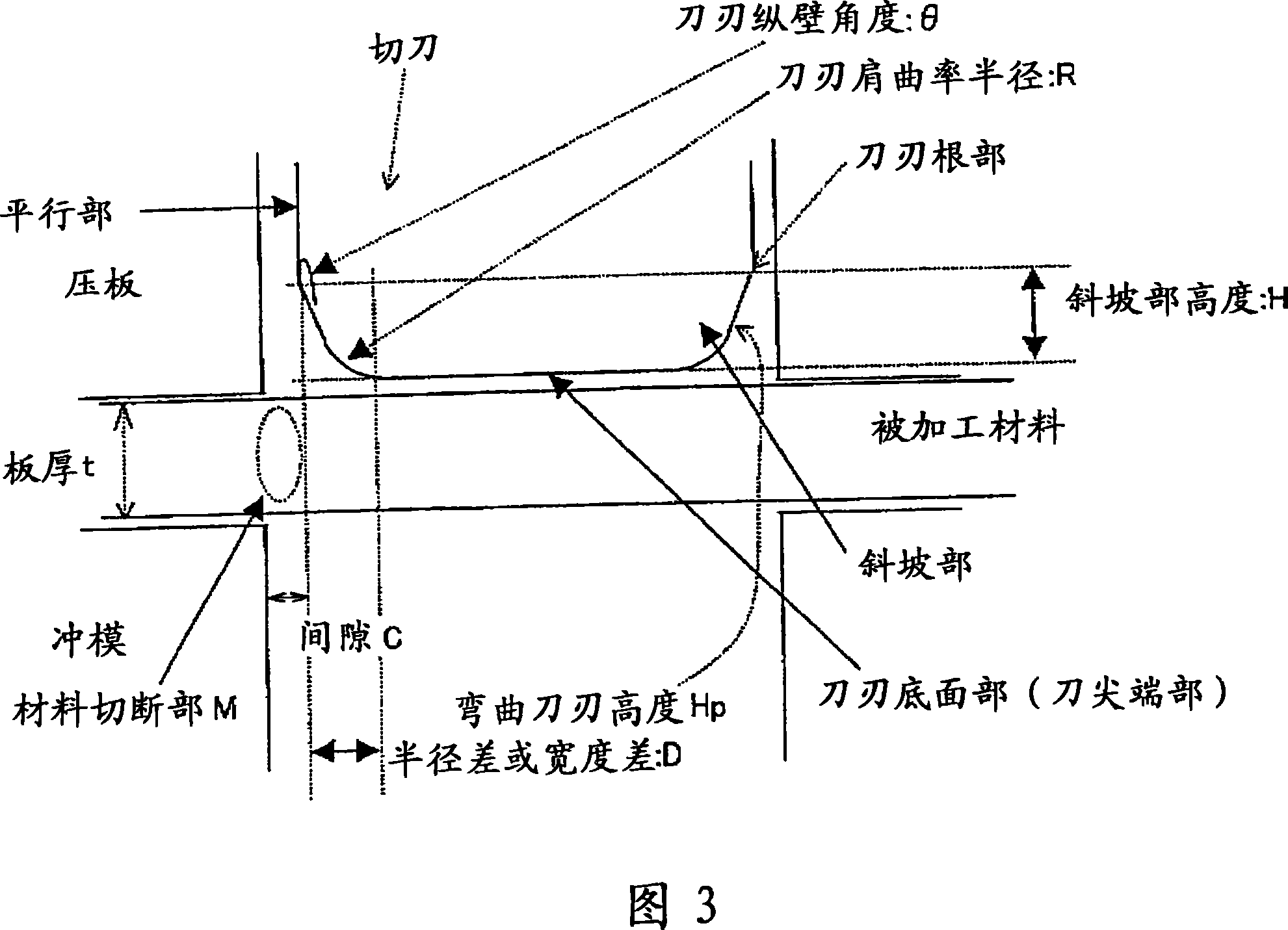

Method used

Image

Examples

Embodiment 1

[0137] Slabs having the chemical compositions shown in Table 1 were cast. These slabs are heated to 1050-1350° C., hot-rolled to a finish rolling temperature of 800-900° C., and rolled at a coiling temperature of 450-680° C. to produce hot-rolled steel sheets with a thickness of 4 mm. Next, after pickling, cold rolling was performed to form a cold-rolled steel sheet having a thickness of 1.6 mm. Then heated to Ac 3 After the austenite zone above 950°C, hot forming processing is carried out. Regarding the atmosphere of the heating furnace, the hydrogen content and dew point were changed. The conditions are shown in Table 2 and Table 3. The tensile strengths are 1523MPa and 1751MPa respectively.

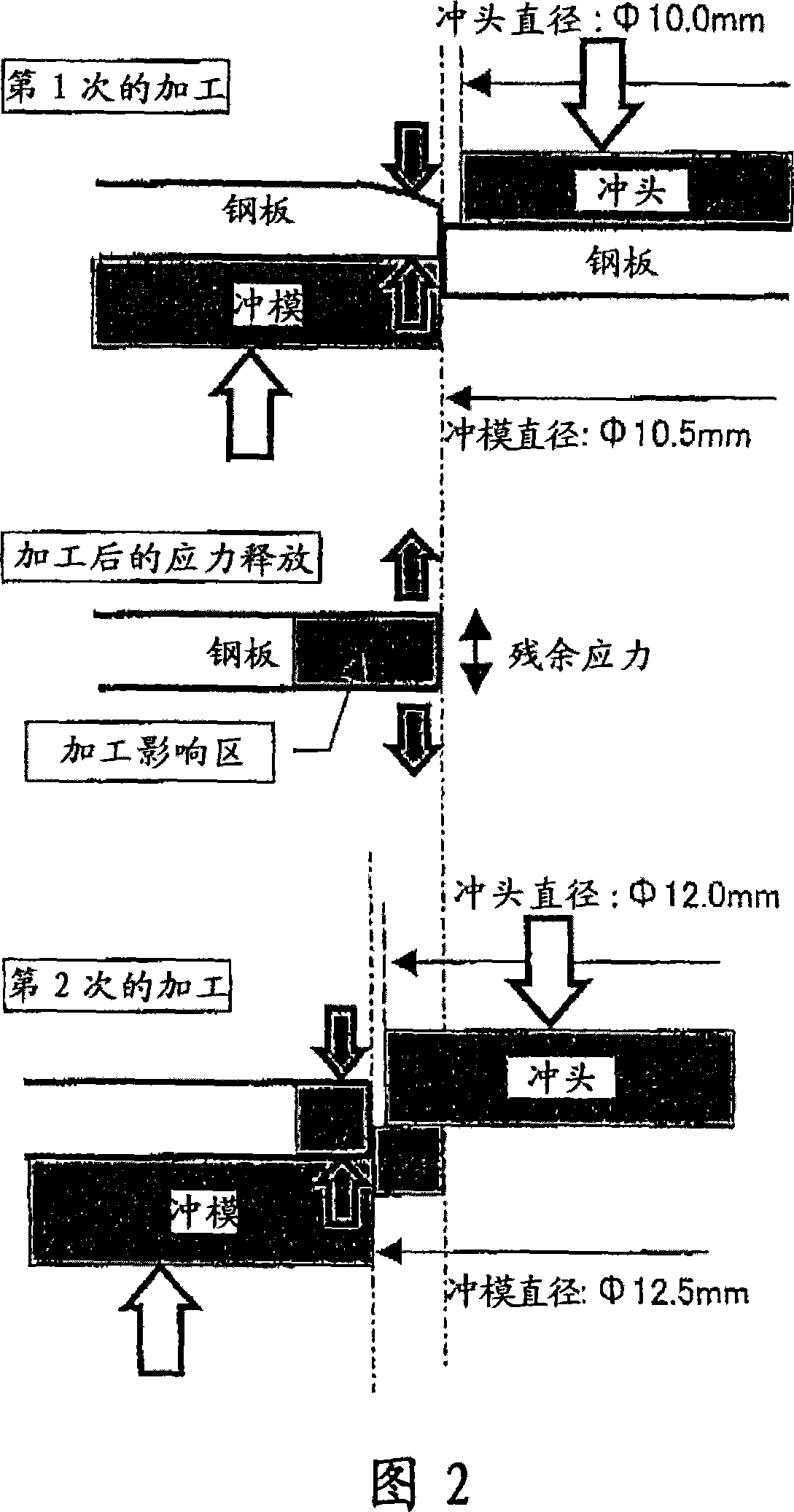

[0138] When evaluating the punched and pierced parts, these molded products were cut out to a size of 100mm×100mm to prepare test pieces, and the center was punched with a Φ10mm punch with a gap of 15%, and then tested under various conditions. 2 processing. In addition, when eva...

Embodiment 2

[0147] Slabs having the chemical compositions shown in Table 4 were cast. These slabs are heated to 1050-1350° C., hot-rolled to a finish rolling temperature of 800-900° C., and rolled at a coiling temperature of 450-680° C. to produce hot-rolled steel sheets with a thickness of 4 mm. Then, after pickling, cold rolling was performed to form a cold-rolled steel sheet having a thickness of 1.6 mm. In addition, a part of the cold-rolled sheet was subjected to hot-dip aluminum plating, hot-dip aluminum-zinc plating, alloying hot-dip galvanizing, and hot-dip galvanizing. Table 5 shows examples of plating types. Then those cold-rolled steel sheets and surface-treated steel sheets are heated through a furnace until they are heated at Ac 3 After the austenite zone above 950°C, hot forming is performed. Regarding the atmosphere of the heating furnace, the hydrogen content and dew point were changed. The conditions are shown in Table 6.

[0148] Figure 14 shows a cross-section of t...

Embodiment 3

[0167] Slabs having the chemical compositions shown in Table 4 were cast. These slabs are heated to 1050-1350° C., hot-rolled to a finish rolling temperature of 800-900° C., and rolled at a coiling temperature of 450-680° C. to produce hot-rolled steel sheets with a thickness of 4 mm. Then, after pickling, cold rolling was performed to form a cold-rolled steel sheet having a thickness of 1.6 mm. In addition, a part of the cold-rolled sheet was subjected to hot-dip aluminum plating, hot-dip aluminum-zinc plating, alloying hot-dip galvanizing, and hot-dip galvanizing. Table 5 shows examples of plating types. Then those cold-rolled steel sheets and surface-treated steel sheets are heated through a furnace until they are heated at Ac 3 After the austenite zone above 950°C, hot forming is performed. Regarding the atmosphere of the heating furnace, the hydrogen content and dew point were changed. The conditions are shown in Table 7.

[0168] Figure 14 shows a cross-section of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com