Table tennis bat handle adhering machine and its control method

A table tennis racket and control method technology, applied to rackets, sports accessories and other directions, can solve the problems of lack of reliability in the sticking position between the racket handle patch and racket body, affecting the yield, etc., and achieves simple structure, convenient operation, The effect of improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

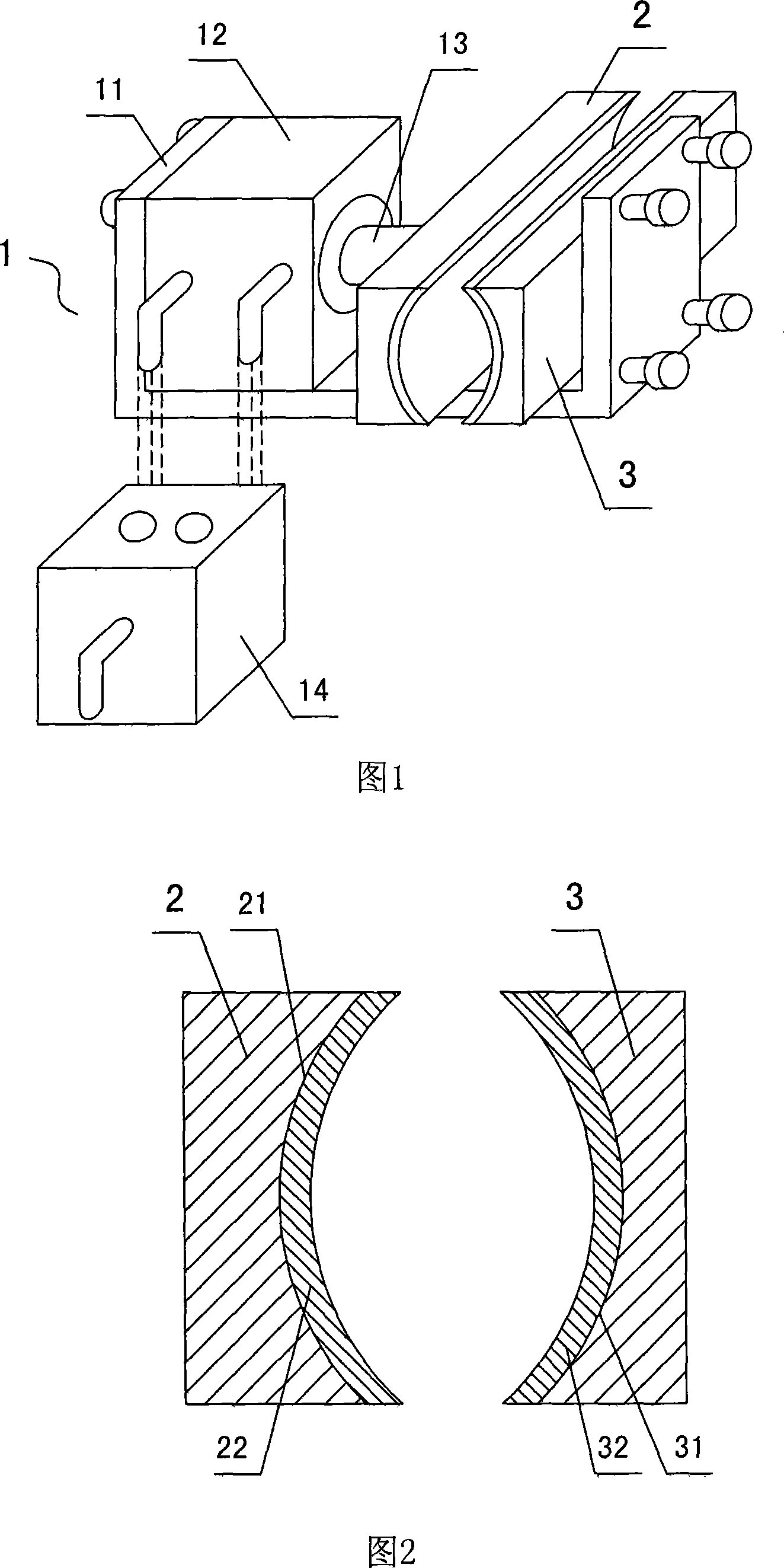

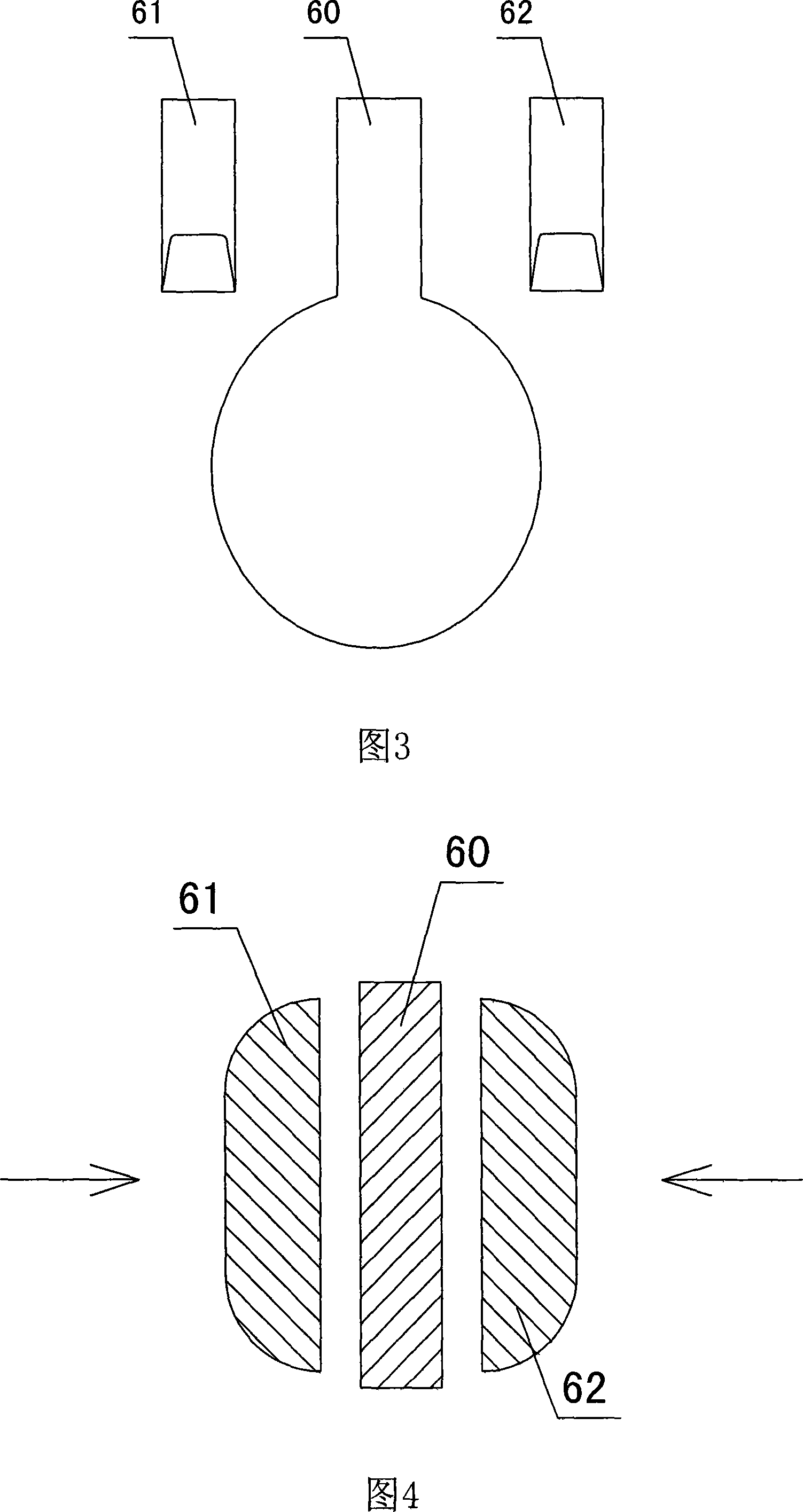

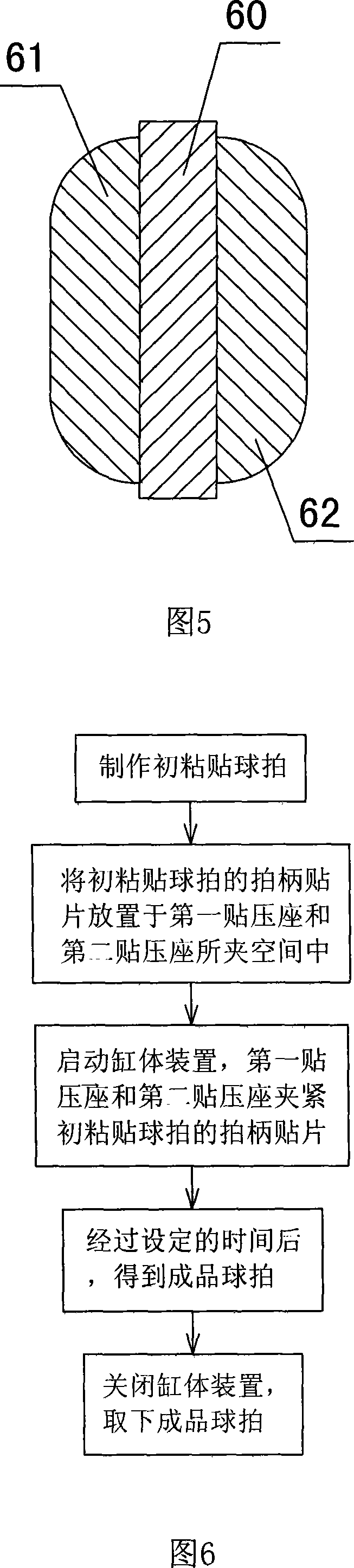

[0045] According to Fig. 1, the present invention includes a cylinder device 1 and a first pressing seat 2 driven by the cylinder device 1, and a second pressing seat 3 is relatively fixed at the relative position of the first pressing seat 2, specifically, As shown in FIG. 1 , the cylinder device 1 includes a base 11 , a cylinder 12 , a piston rod 13 and a switch 14 .

[0046] As shown in Figure 1, the cylinder 12 is installed on one side of the base 11 (in this embodiment, the left side); the end of the piston rod 13 pulled by the cylinder 12 is connected to the first pressing seat 2; the second pressing seat 3 is installed on the other side of the base 11 (the right side in this embodiment), the position of the second pressing seat 3 corresponds to the position of the first pressing seat 2; the switch 14 and the cylinder body 12 pass through two Two pipes are connected, one of which is an input pipe, and the other is an output pipe. The switch 14 controls the motion state o...

Embodiment 2

[0062] As shown in Figure 9, the main difference between this embodiment and Embodiment 1 is that in this embodiment, four cylinder devices 1 are arranged in parallel, and each cylinder device 1 controls the corresponding first pressing seat 2 respectively, The four cylinder devices 1 are connected through the valve body 4 (in this embodiment, the valve body 4 is a three-way valve), and a total pressure source 5 provides air pressure or hydraulic pressure to each cylinder device 1 through the valve body 4 .

[0063] The structure, principle and operation process of other parts of this embodiment are the same or similar to those described in Embodiment 1, and will not be repeated here.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap