Experimental device for researching influence of pressure on elbow abrasion

An experimental device and pressure technology, applied in the direction of testing wear resistance, etc., can solve problems such as fatigue cracks in pipeline parts, less impact research, solid-liquid two-phase wear, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

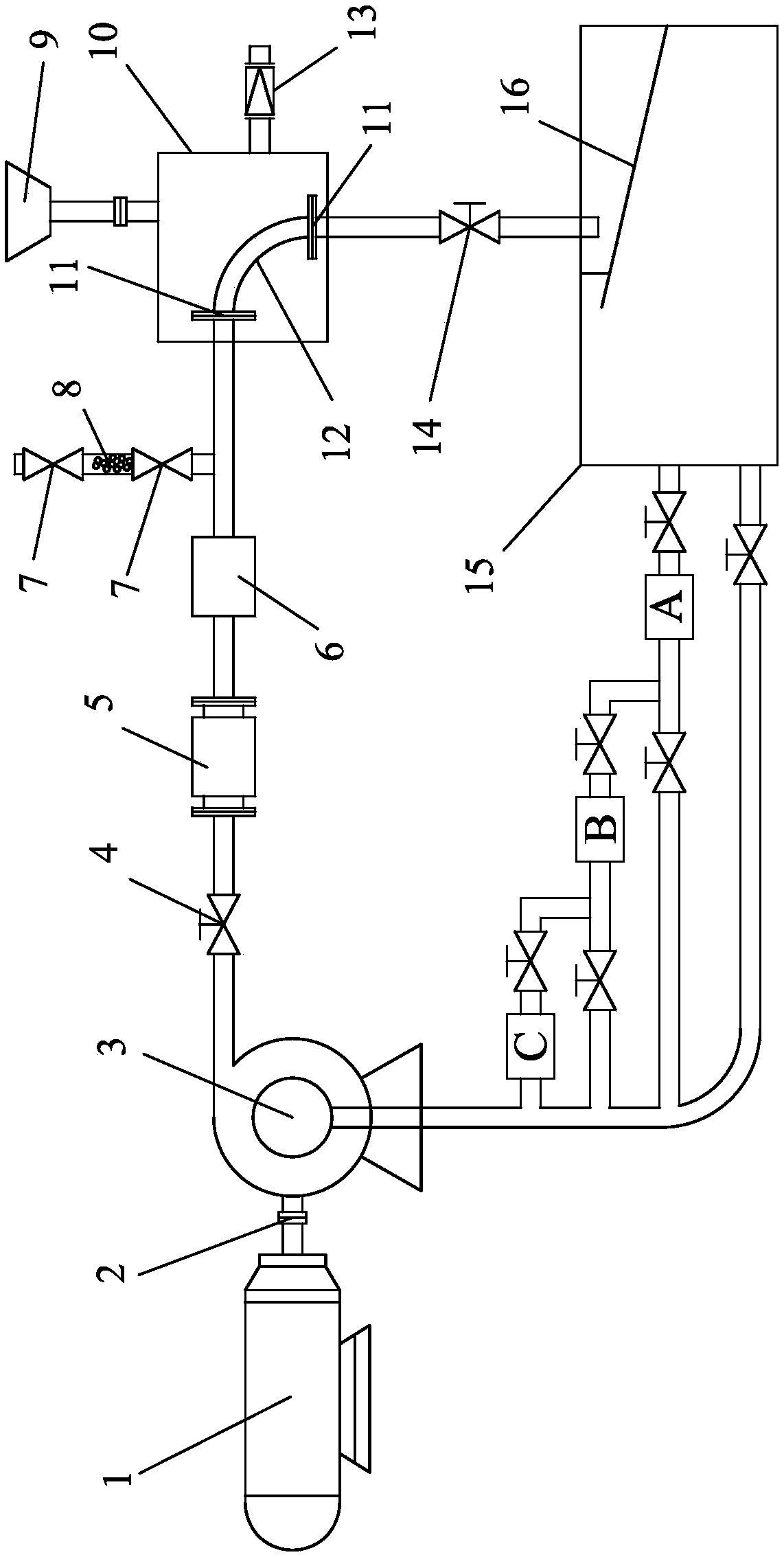

[0017] The present invention adopts a single variable method, and only studies the influence of pressure on the wear amount of the solid-liquid two-phase transportation pipeline; the present invention is based on the principle that centrifugal pumps with the same characteristics are connected in series without changing the flow rate of the circuit, but only changing the head. Further illustrate by specific embodiment below.

[0018] The experimental device for studying the influence of pressure on the elbow wear shown in the accompanying drawings includes a group of centrifugal pumps, a regulating valve 4, a test elbow 12 and a water tank 15 which are sequentially connected to form a circulation loop through pipelines; Flowmeter 5, pressure gauge 6, a particle release device 8 is arranged in the pipeline between the pressure gauge and the test elbow, and the outside of the test elbow is covered with a pressure-adjustable airtight box 10, so The top of the water tank is equippe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap