Light source diffusion plate and backlight module

A light source diffusion and backlight module technology, applied in optics, nonlinear optics, diffuser elements, etc., can solve the problems of waste light source, time-consuming chemical manufacturing process, high production cost, etc., and achieve the effect of uniform light brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following description will provide many specific descriptions to provide a thorough understanding of the embodiments of the present invention, wherein the purpose of the drawings is only to illustrate the preferred embodiments of the present invention, not to limit the scope of the present invention.

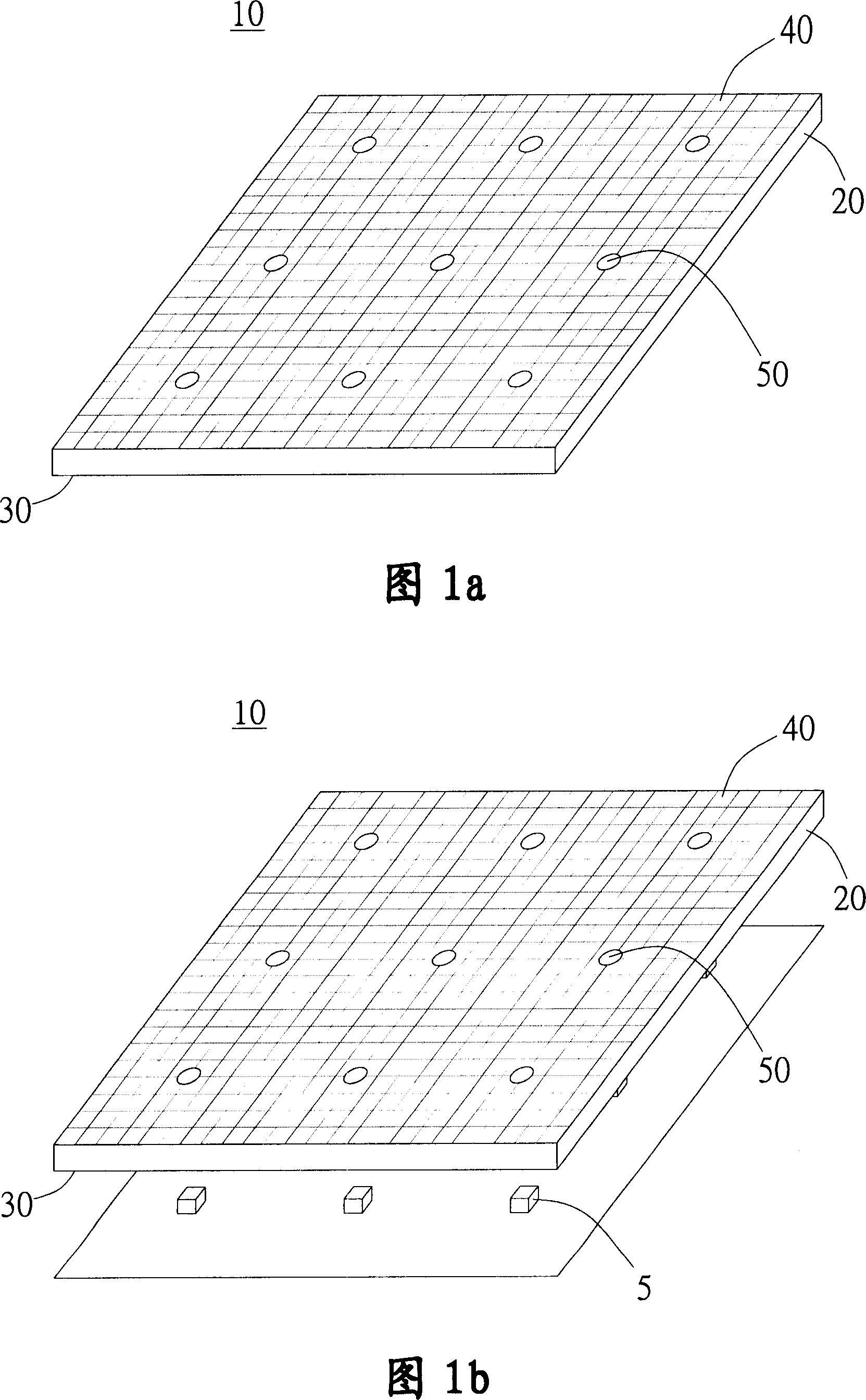

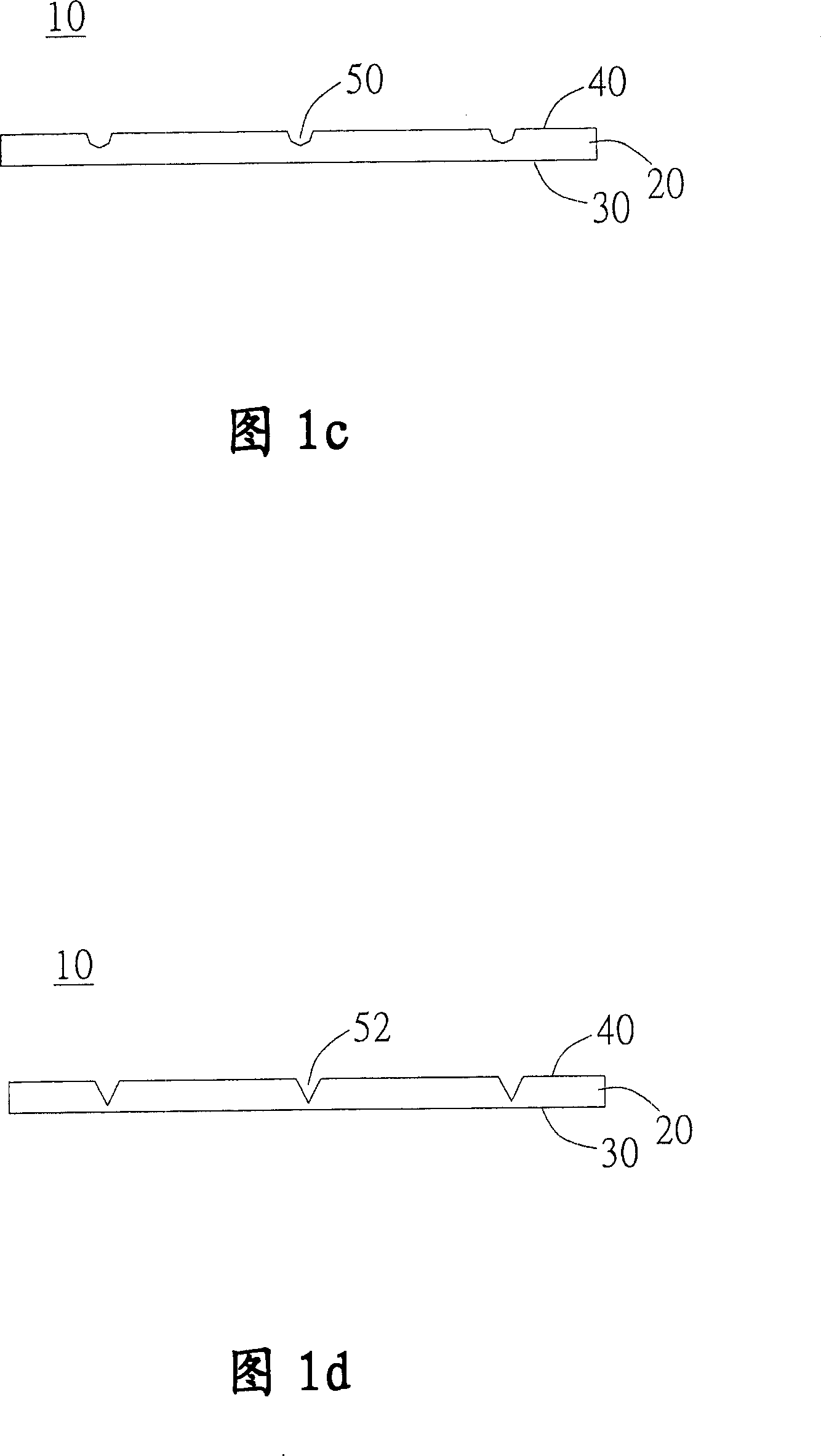

[0031] The present invention provides a light source diffusion plate suitable for backlight modules, which can really achieve the effect of light source intensity redistribution, which uses the strongest angle energy to generate refraction through the light source diffusion plate of the present invention, and is different from that without the light source diffusion plate The weaker energy at a large angle can be superimposed to obtain a new angular energy distribution, so the spatial distribution of the original point spread function (PSF) of the original light source can be extended, so that the backlight that was originally a point light source or a line light source...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com