Heat exchanger with temperature-controlled valve

A technology of heat exchangers and temperature sensors, applied in heat exchange equipment, indirect heat exchangers, heat exchanger types, etc., can solve the problem of slow temperature detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

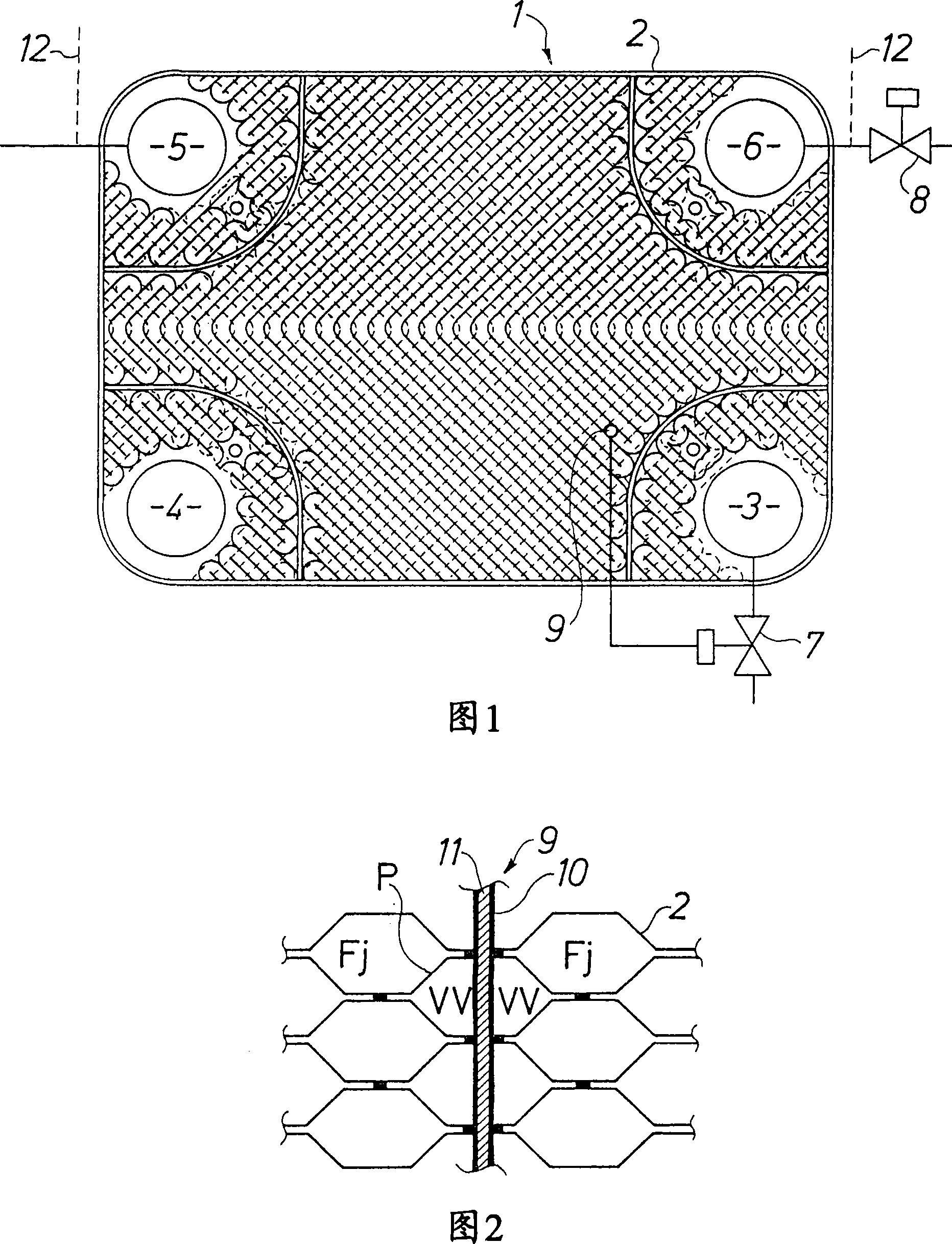

[0012] Plate heat exchangers are well known devices for exchanging heat between two different media. Plate heat exchangers are used in many different applications, and although the invention has been specifically developed as a heat exchanger for supplying hot water using district heating, the invention is not limited to any particular application. The present invention is most suitable for various all-brazed plate heat exchangers. In other words, the heat exchanger comprises a plate with a pattern of grooves with inlet and outlet connections for the two media. These boards are placed in an assembly and brazed together to form a unit. Separate channels for the two media circulating countercurrently to one another are formed between the exchangeable plate pairs. This technique is well known and therefore will not be described in detail here.

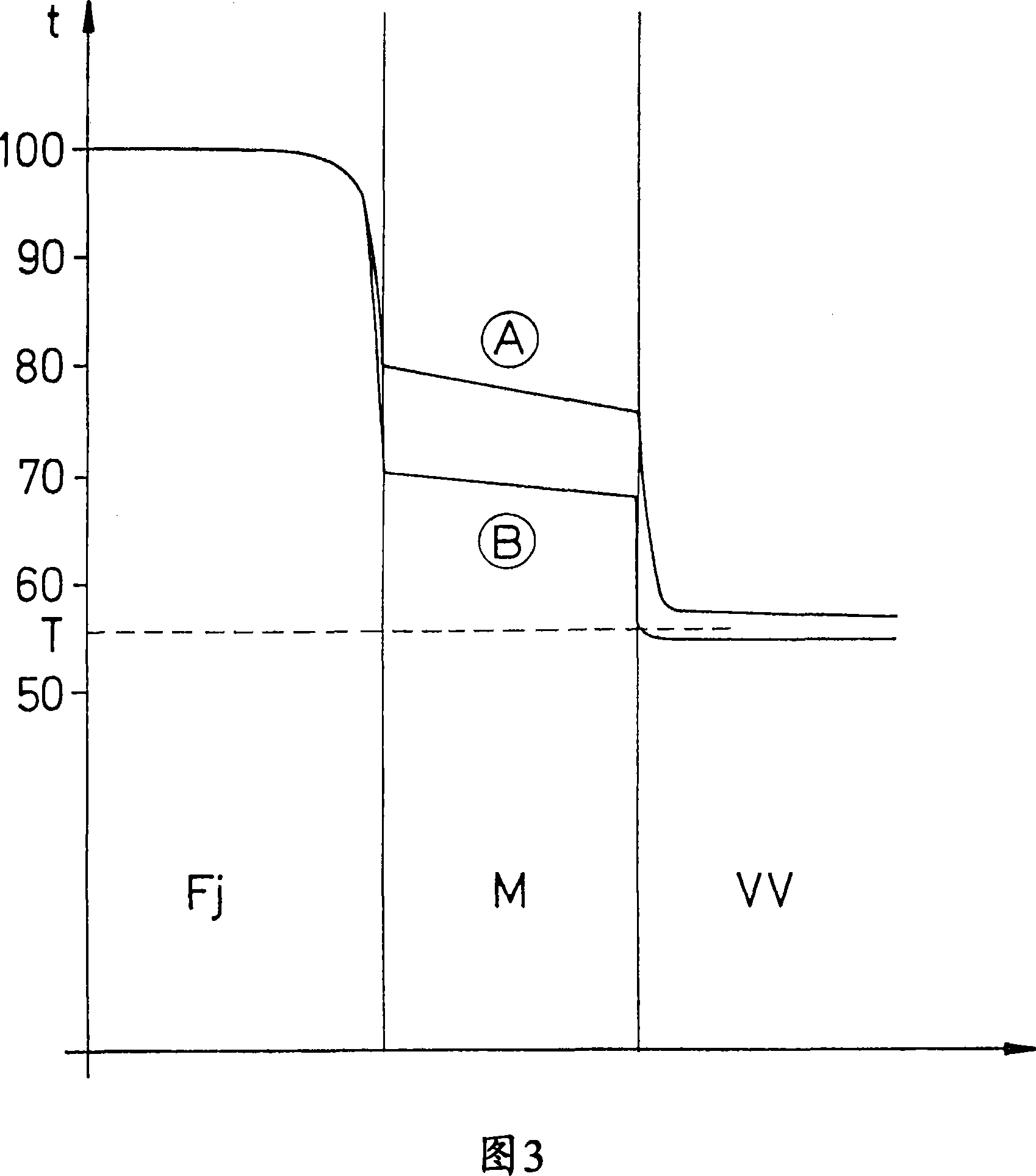

[0013] Figure 1 is a schematic diagram of a heat exchanger for heating water with hot water from a district heating network. The hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat of fusion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com