Method for producing crystal shoes

A production method, the technology of crystal shoes, applied in footwear, clothing, applications, etc., can solve the problems of inability to meet individual needs, high risk, and high cost of metal molds, and achieve low cost, low risk, and short production cycle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] When making wax sheets, they can be made into shoe uppers and soles separately from ordinary shoe molds.

[0023] Commemorative words can also be engraved on the wax shoe mold; in this way, commemorative words are left on the crystal shoe.

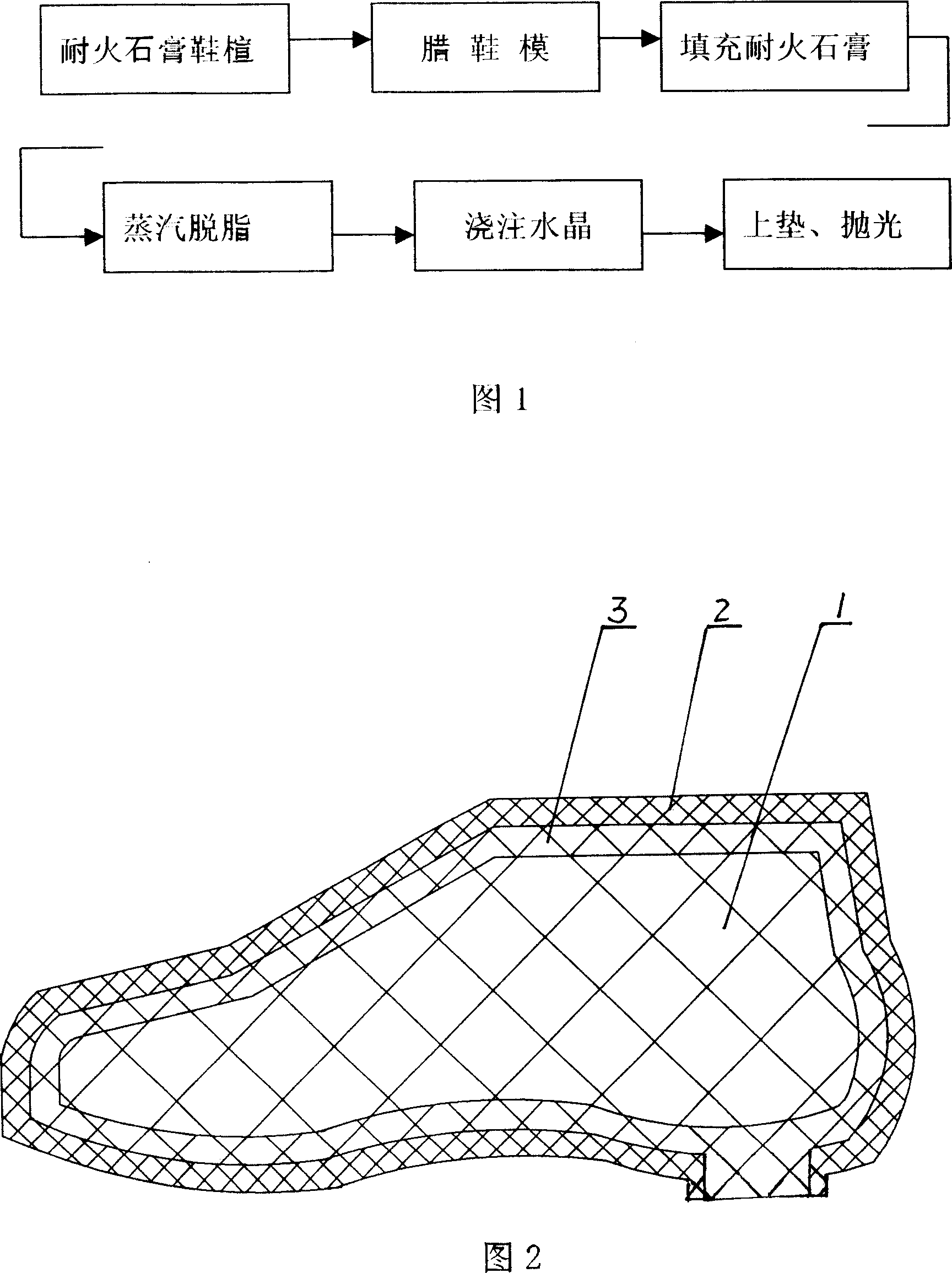

[0024] According to the above process of producing crystal shoes, the latter process: the inside is the female mold 1, the outside is the male mold 2, and the crystal shoe 3 is between the female mold 1 and the male mold 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com