Paper tray unit

A tray and paper conveying technology, which is applied in the direction of object separation, pile separation, function indication, etc., can solve the problems of unoptimized space saving and large height of ADF73, and achieve the effect of space saving and height suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

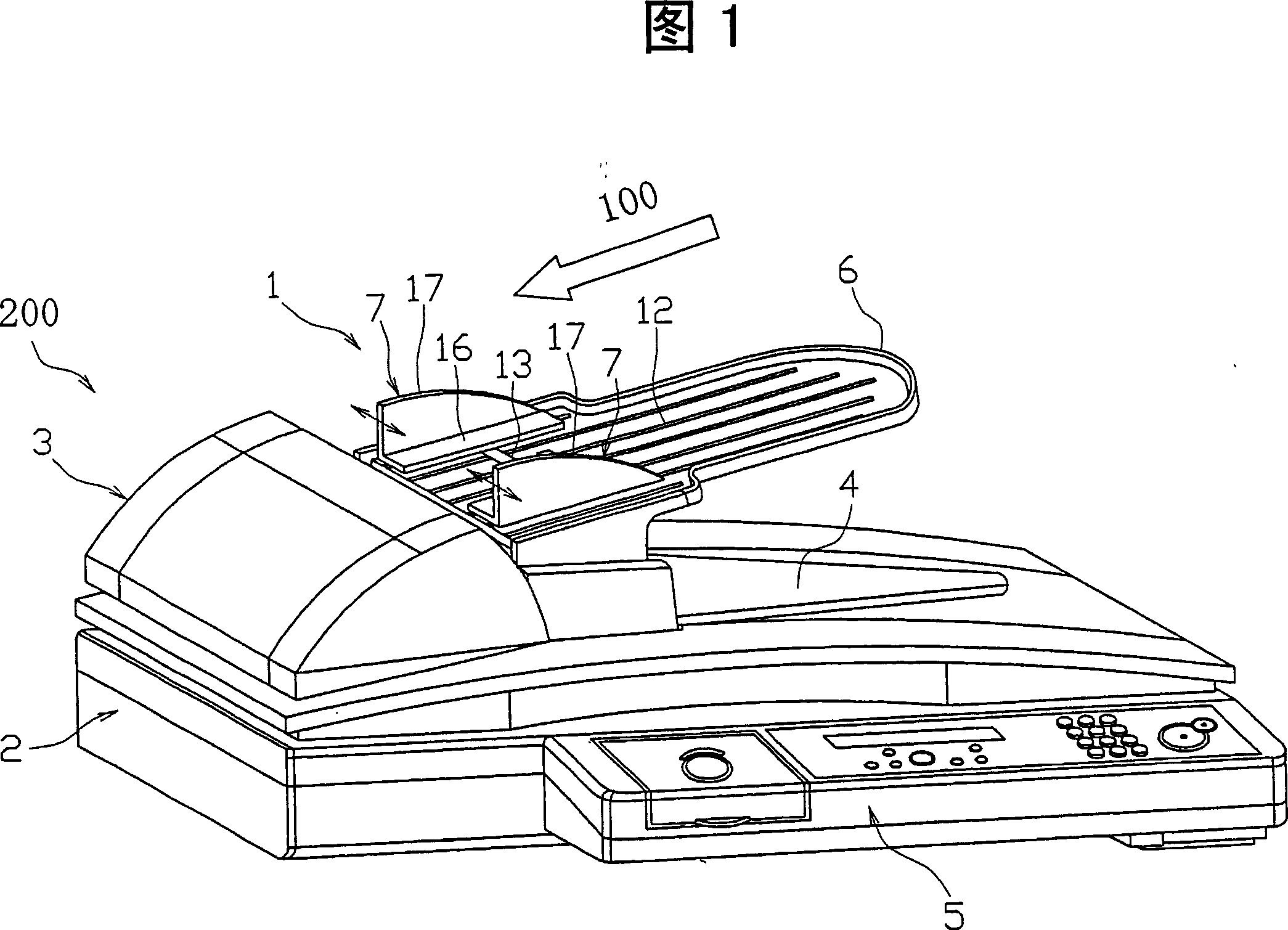

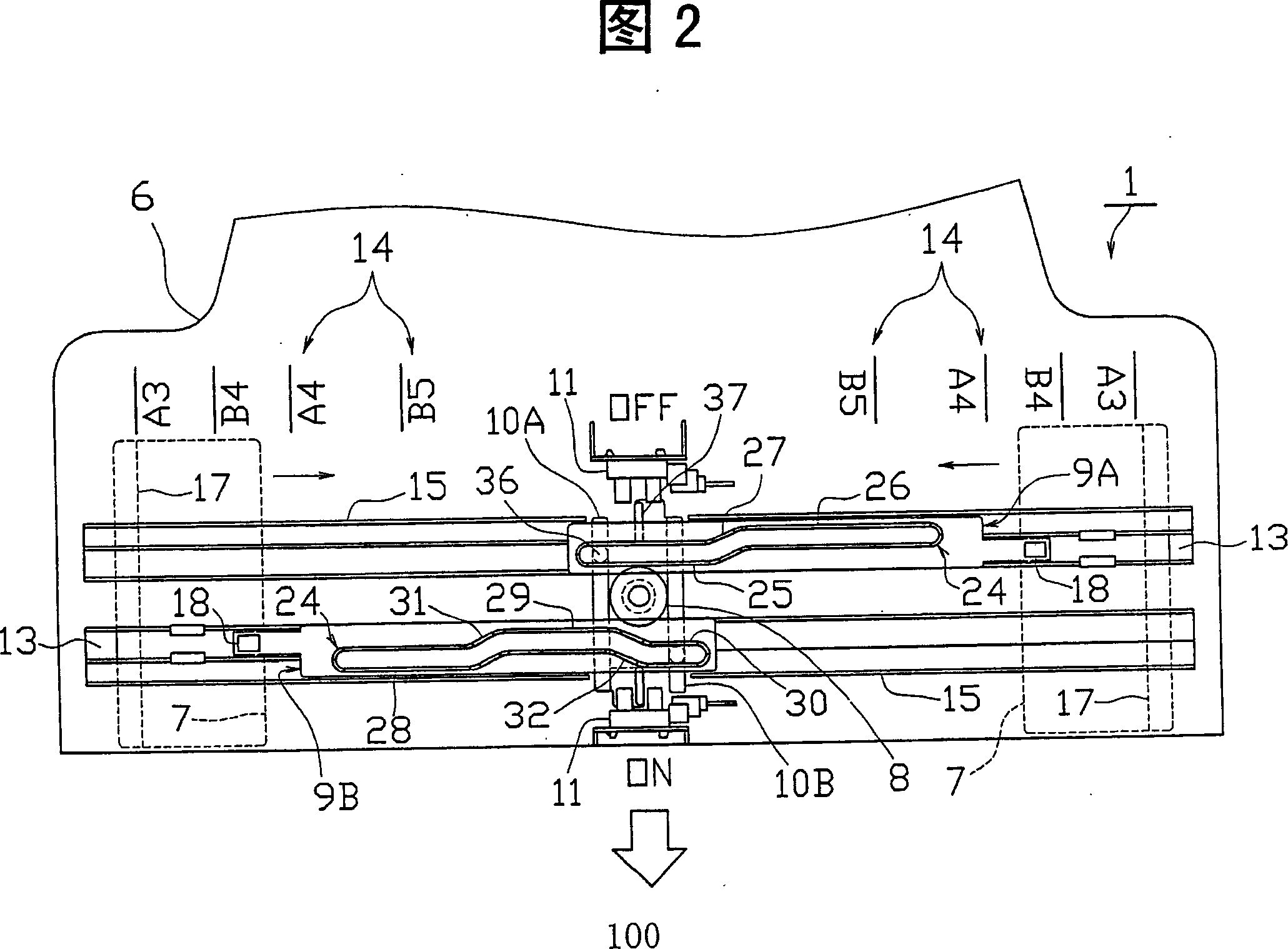

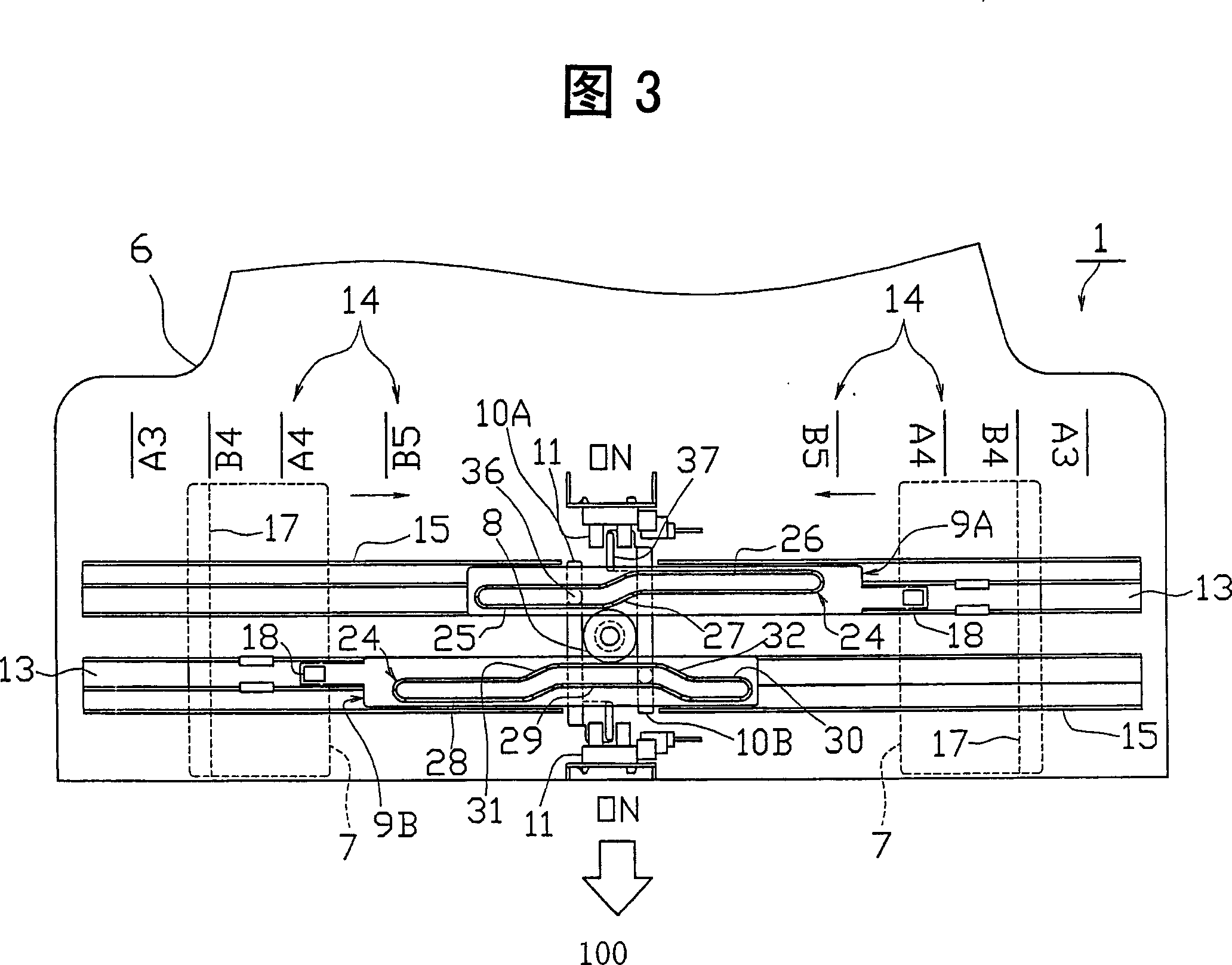

[0021] Hereinafter, a document tray unit according to an embodiment of the present invention will be described based on the drawings. FIG. 1 is a schematic perspective view showing the appearance of an image reading apparatus 200 including a document tray unit 1 according to the first embodiment. The image reading device 200 is provided on top of a copy-facsimile complex machine or the like, and is used to read image information of a document to be copied or sent by facsimile. The image reading device 200 includes a device main body 2 in which an image reading unit (not shown) is accommodated in a hollow casing, an ADF 3 arranged on the upper surface of the device main body 2, and an ADF 3 for placing the image reading unit to be read. A document tray unit (paper tray unit) 1 for a document (paper) to be picked up, a paper output tray 4 for storing a document that has been read, and a front surface of the device main body 2 provided on the front surface of the image reading de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com