Yarn production system

A production equipment and spinning technology, which is used in the production of man-made yarn complete sets of equipment, filament generation, textiles and papermaking, etc. Space saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

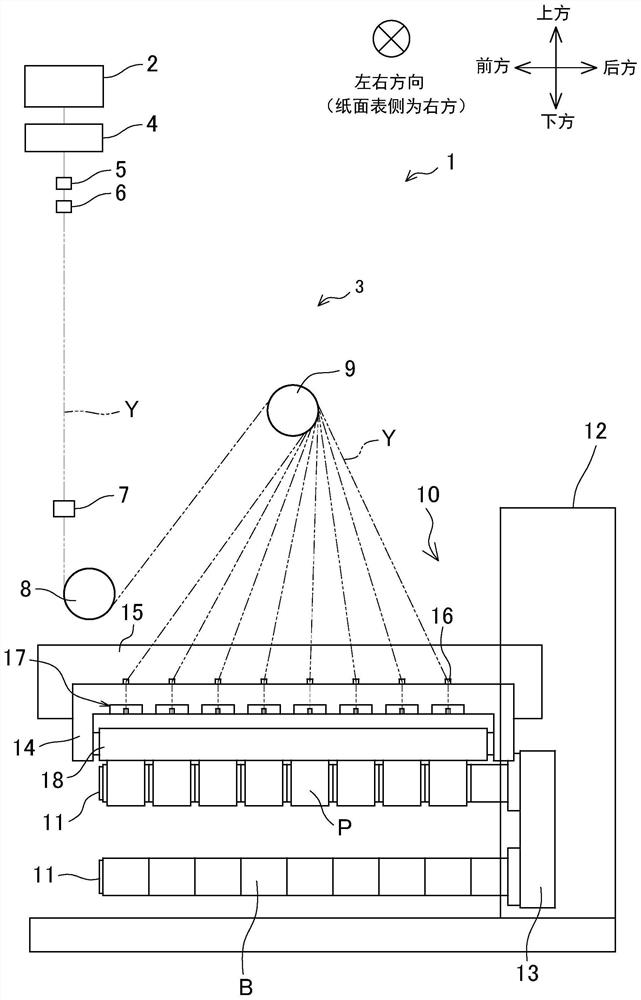

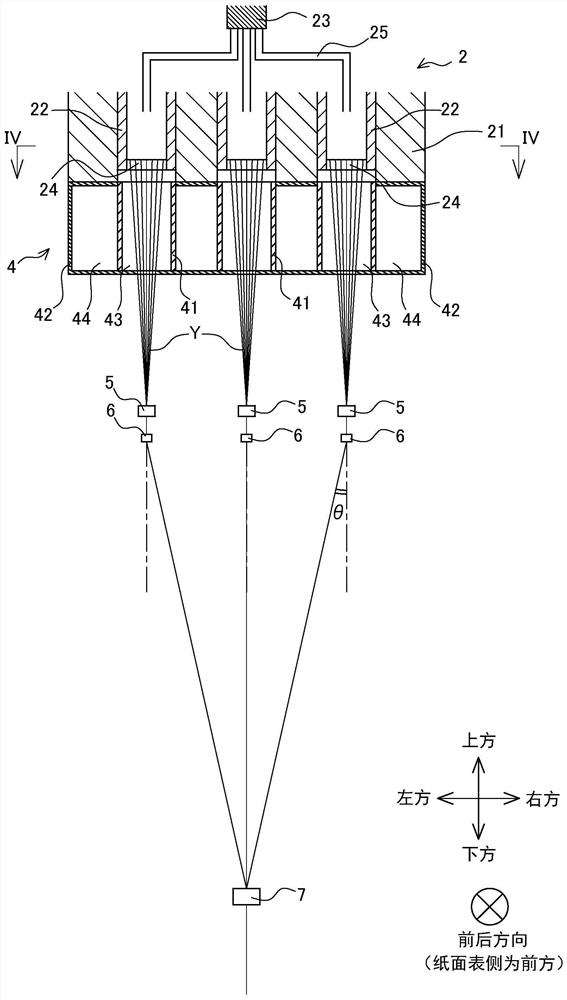

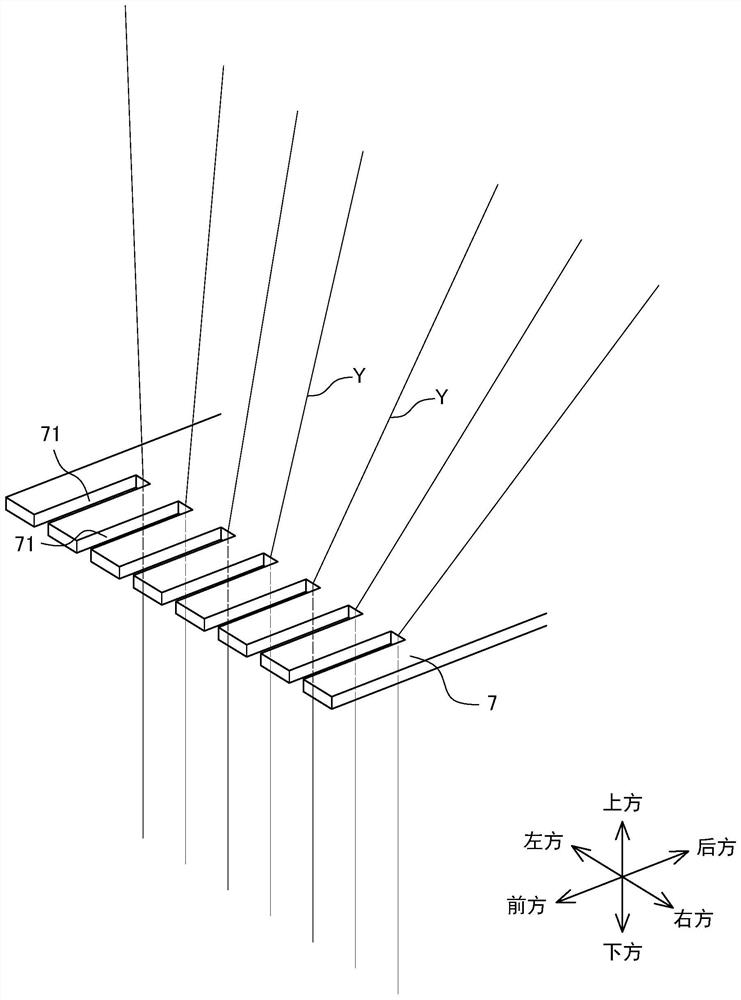

[0042] (Overall structure of spinning production equipment 1)

[0043] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings. figure 1 It is a side view of the spinning production facility 1 according to this embodiment. figure 2 It is a partial sectional view of the spinning device 2 and the cooling device 4 . In addition, the following will figure 1 The front, back, left, right, up, and down directions in are defined as the front, back, left, right, up, and down directions of the spinning production equipment 1 .

[0044] Spinning production equipment 1 such as figure 1 A spinning device 2 and a spinning draw 3 are shown. The spinning device 2 is a device that spins the molten polymer as a yarn Y downward, such as figure 2 As shown in FIG. 1 , a spinning beam 21 and a plurality of spinning packs 22 attached to a housing portion formed under the spinning beam 21 are provided. The spinning drawing device 3 is a devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com