battery module

A technology of battery modules and battery cells, which is applied in the direction of batteries, secondary batteries, battery pack components, etc., and can solve problems such as connector plugging and unplugging obstacles, height and dimension increase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Hereinafter, an embodiment of the battery module of the present invention will be described with reference to the drawings. It should be noted that the drawings are viewed along the direction of the reference numerals.

[0038] [Battery Module]

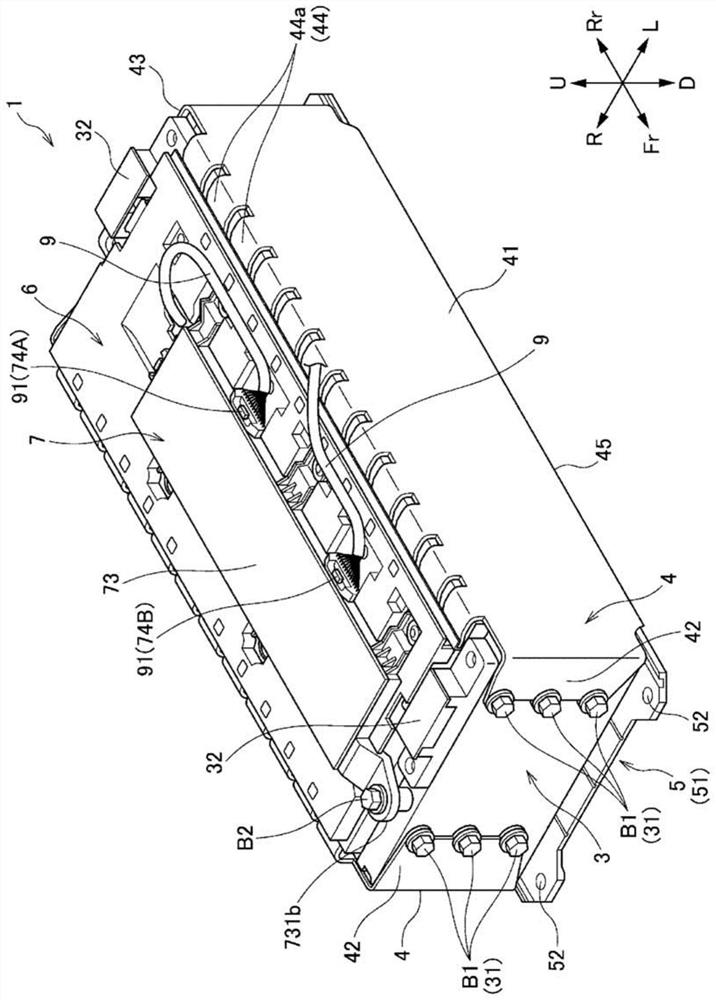

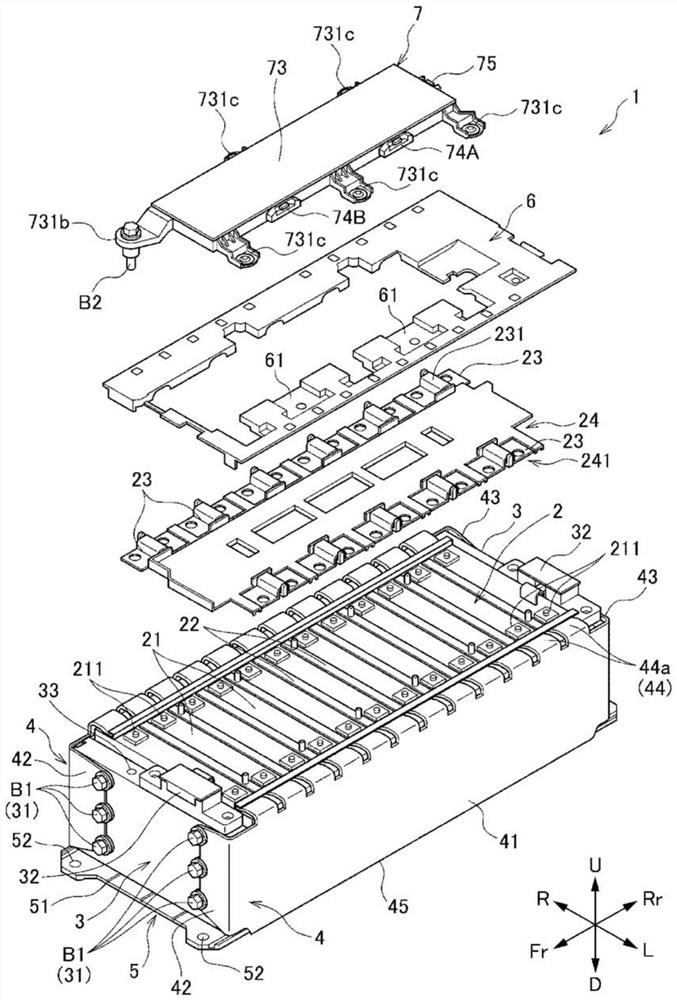

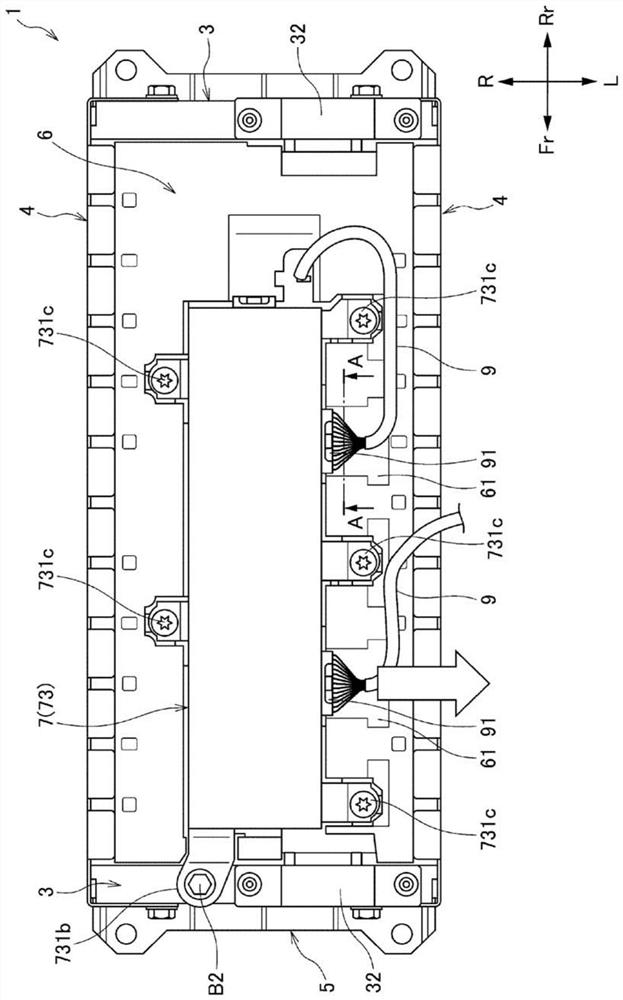

[0039] like Figure 1 to Figure 3 As shown, the battery module 1 according to the present embodiment includes a battery cell stack body 2 composed of a plurality of battery cells 21 stacked in the front-rear direction, and the battery cell stack body 2 has a front surface, a rear surface, a left surface, and a right surface. , upper surface, and lower surface; a pair of end plates 3, which are arranged on the front and rear surfaces of the battery cell stack 2; a pair of side frames 4, which are arranged on the left and right surfaces of the battery cell stack 2, A pair of end plates 3 are connected; the lower plate 5 is arranged on the lower surface of the battery cell stack body 2; the sensor device 7 is arranged on the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com