Relay with reduced leakage current

一种继电器、漏电路径的技术,应用在电磁继电器、继电器、电磁继电器详细信息等方向,能够解决发生漏电流等问题,达到减小漏电流、漏电路径延长、延长漏电路径的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

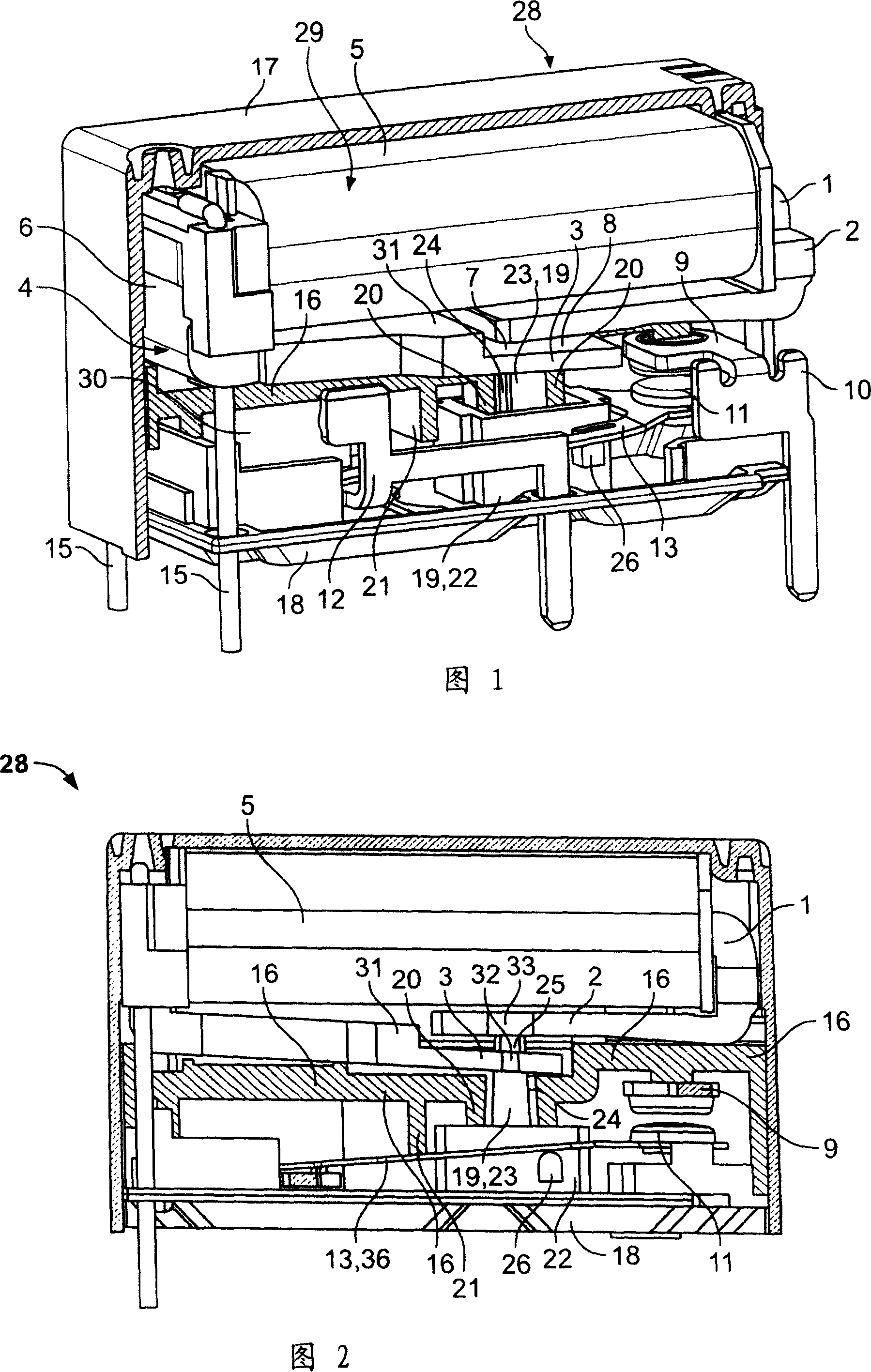

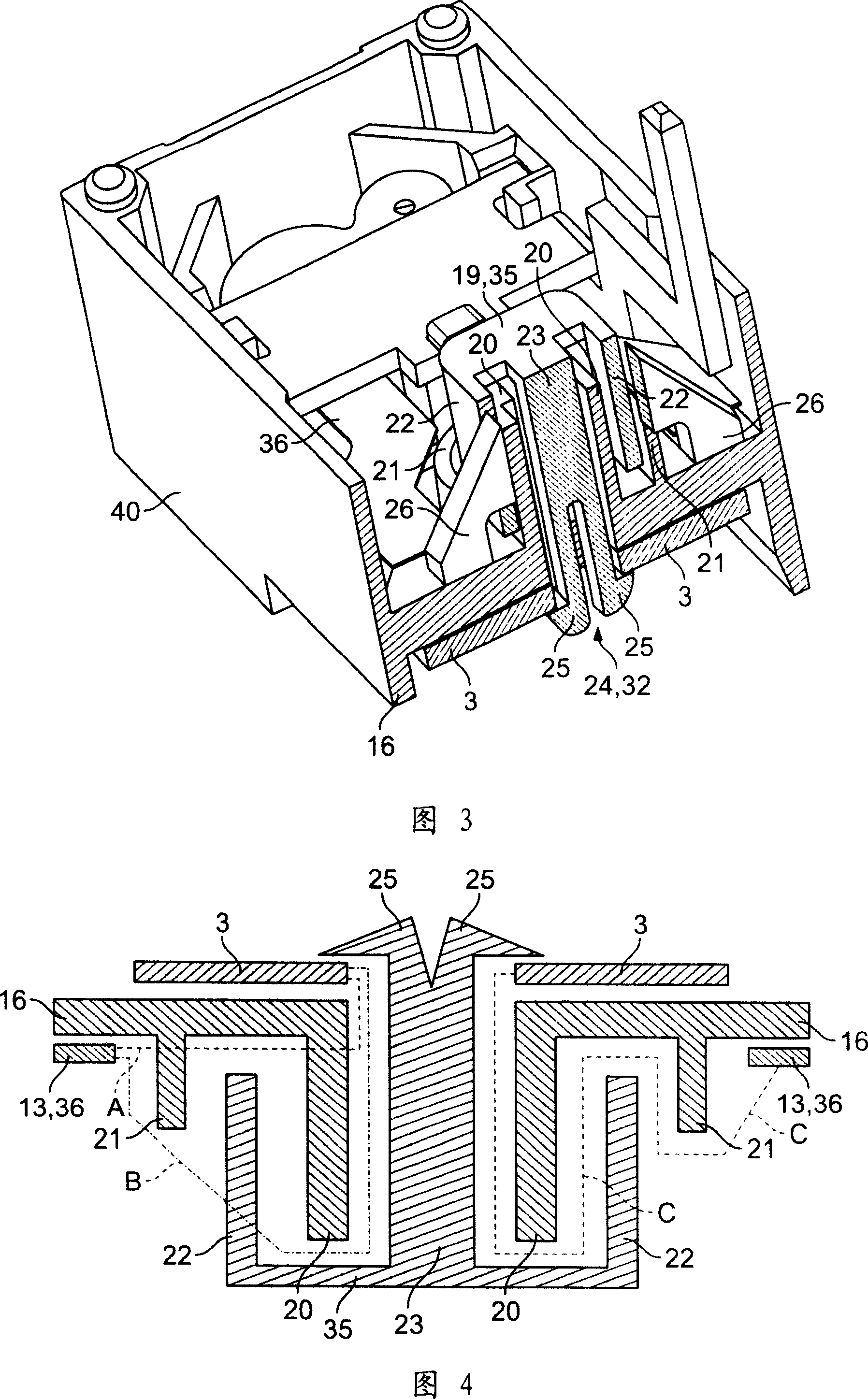

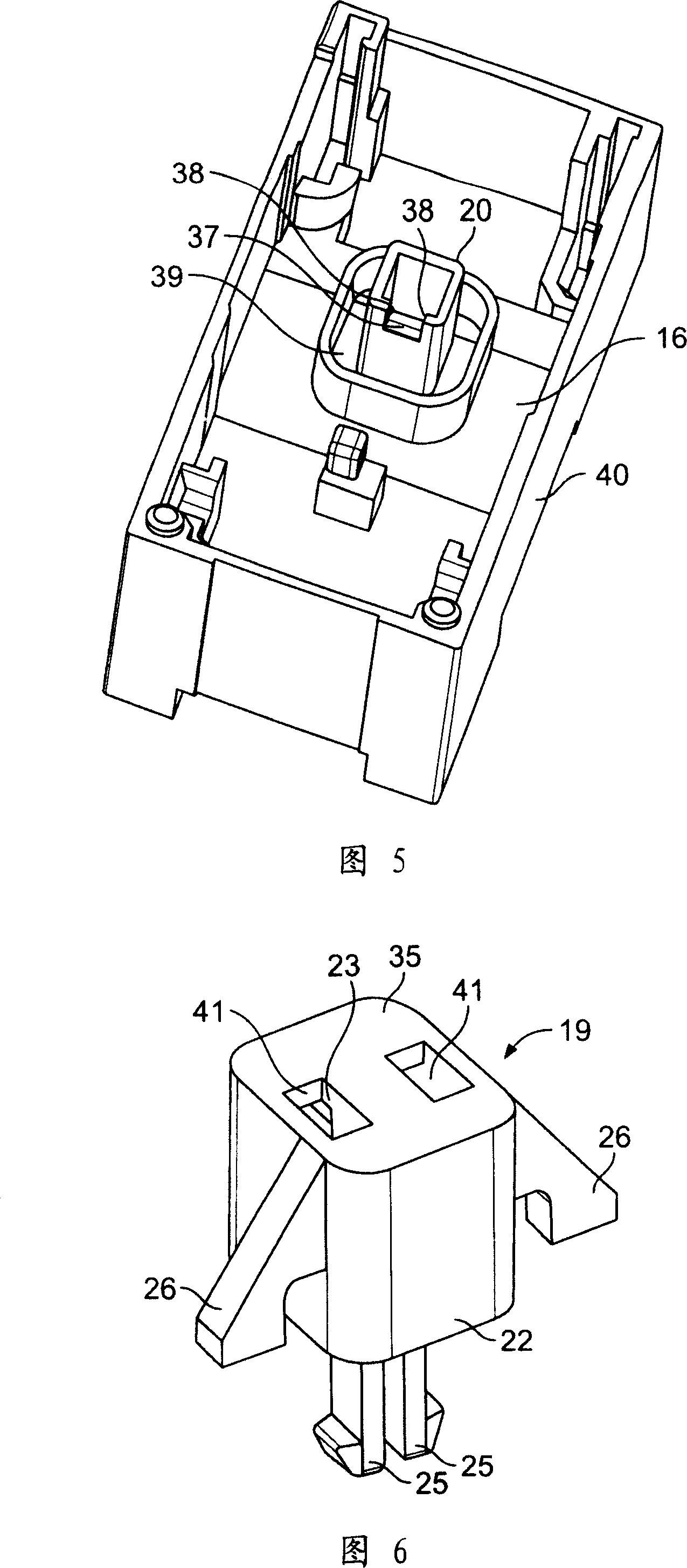

[0025] FIG. 1 shows a partially cutaway perspective view of a relay 28 with a magnetic system 29 and a contact system 30 . The magnetic system 29 and the contact system 30 are separated from each other by the base plate 16 . The magnetic system 29 is positioned on the upper side of the base plate 16 and the contact system 30 is positioned on the bottom side of the base plate 16 . The magnetic system 29 is in active contact with the contact system 30 via an actuator 19 which is guided through the opening 24 of the base plate 16 . Because of the small design and insignificant thickness of the base plate 16 , there is a risk of leakage currents developing between the contact system 30 and the magnetic system 29 . In order to reduce this leakage current, the substrate 16 has a first wall 20 formed on the bottom side of the substrate 16 which surrounds the opening 24 . Furthermore, in a further embodiment, the base plate 16 has a second wall 21 at a distance from the first wall 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com