Meat mincer

A meat cutting machine and rack technology, which is applied in metal processing and other directions, can solve the problems of increased workload, unstable effect, and failure to meet the requirements of automatic machining, so as to save time and improve the effect of automation procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

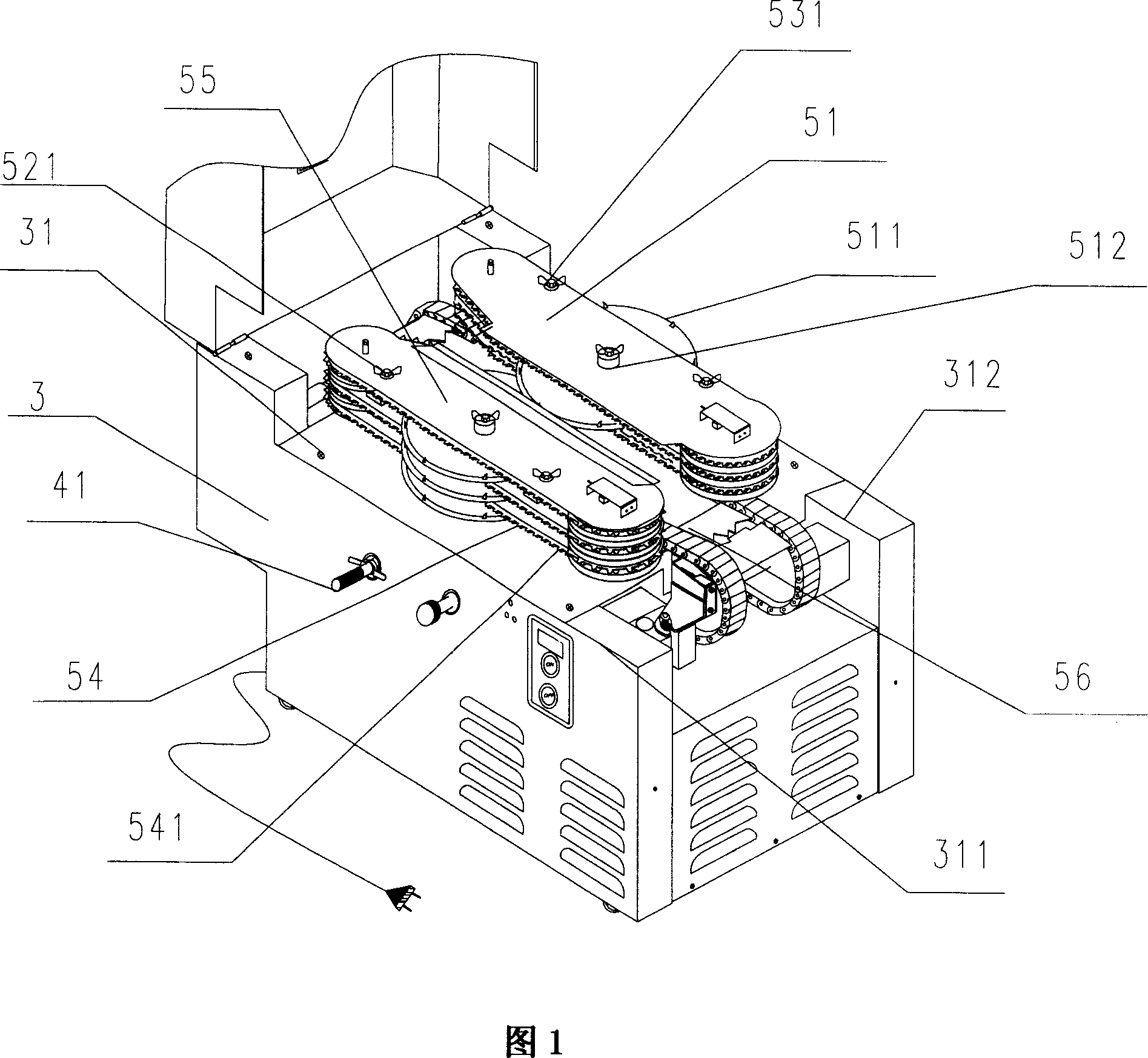

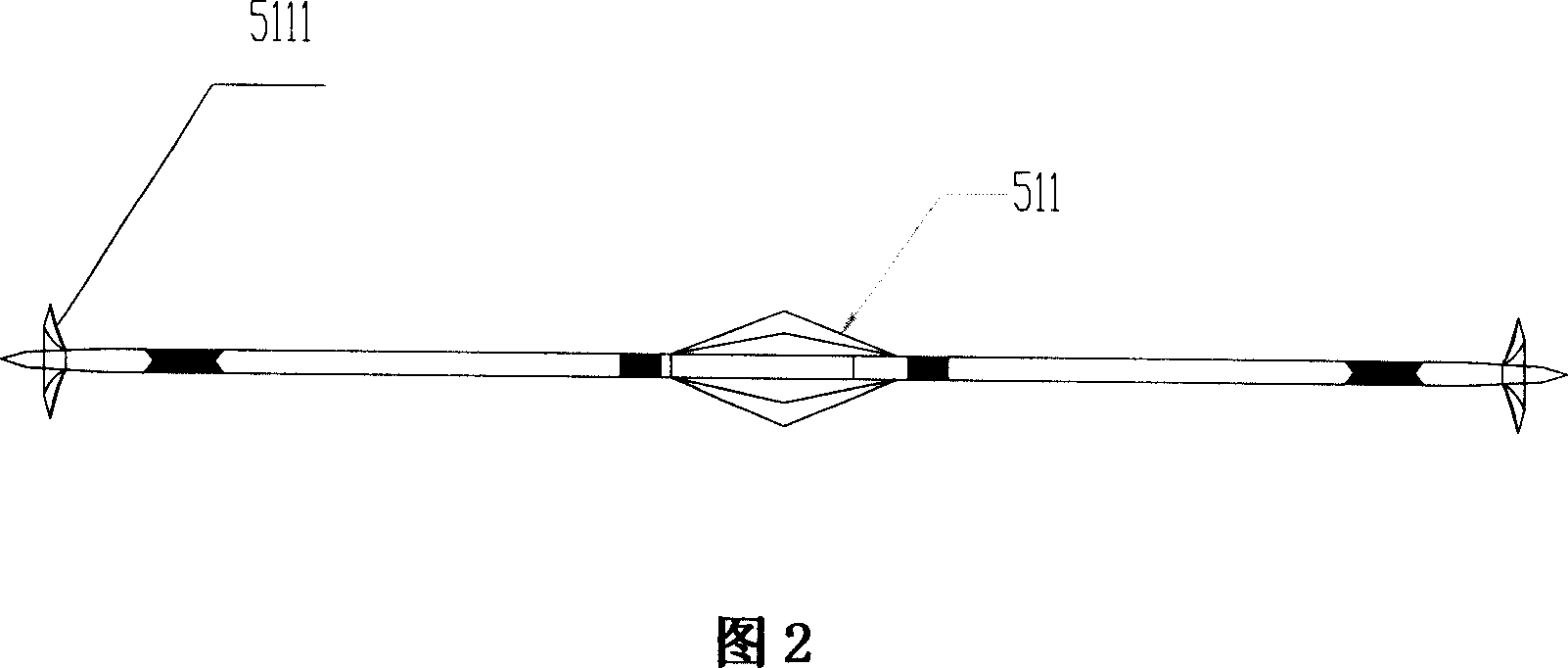

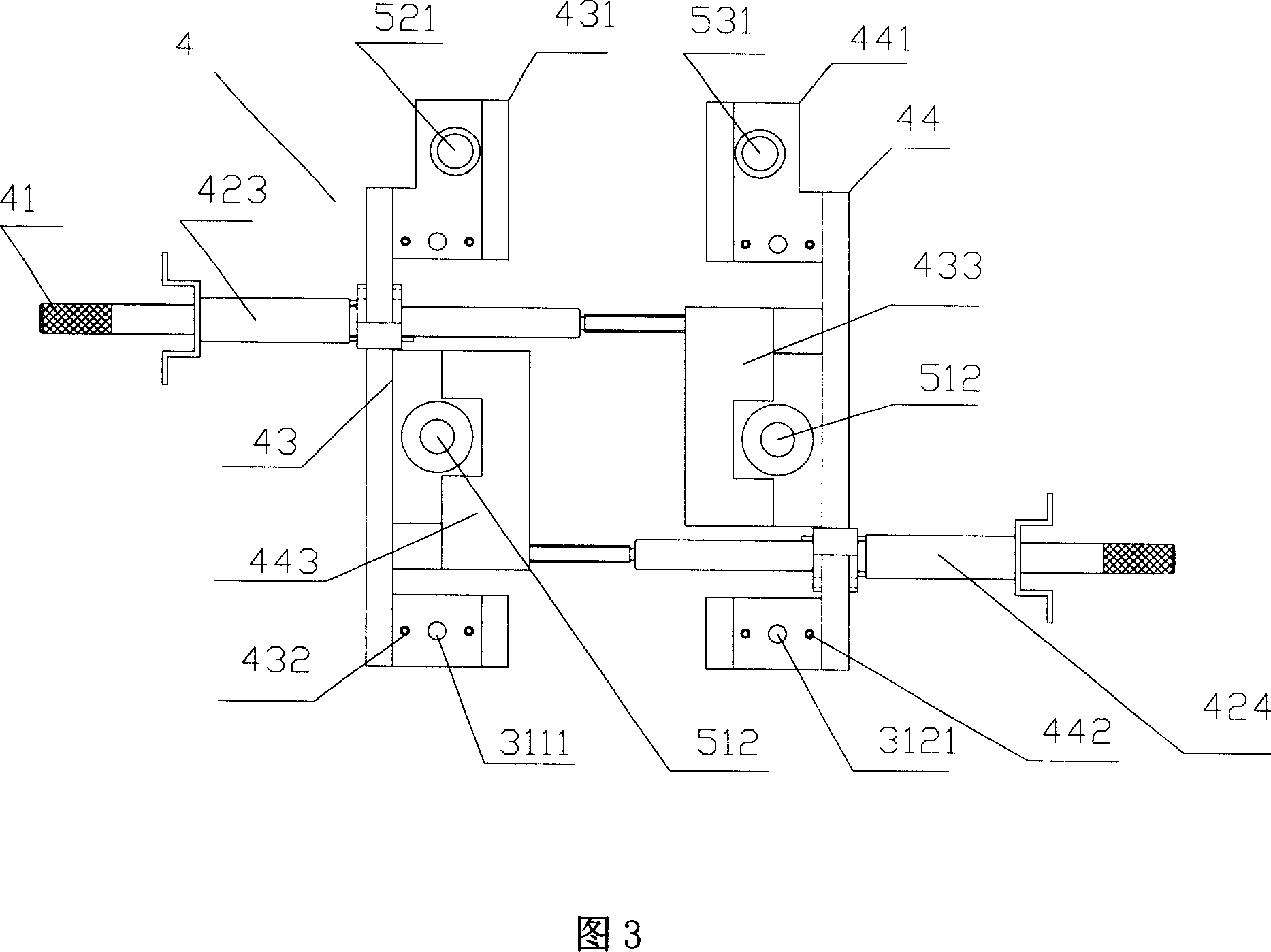

[0015] Please refer to Fig. 1, Fig. 2, Fig. 3, Fig. 4 and shown in Fig. 5, a kind of meat cutting machine of the present invention comprises motor (figure not shown), and this motor is arranged in frame 3, the top of frame 3 A rack platform 31 is provided. There is a storage space (not labeled) in the frame 3, and the above-mentioned motor is arranged in the storage space of the above-mentioned frame 3, and a set of linkage mechanism 4 is further arranged in the above-mentioned storage space, and a linkage mechanism 4 protrudes outside the frame 3. The operating shaft 41 of the frame. There are receiving parts 311 and 312 on both sides of the frame platform 31. Three receiving shafts 3111 protrude from the receiving part 311, and three receiving shafts 3121 protrude from the receiving part 312. The above six receiving shafts are fan-shaped receiving sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com