Prism lens and back-light molding set therewith

一种背光模组、棱镜片的技术,应用在棱镜、光导、光学等方向,能够解决出射光亮度降低、大光线传输损失、难满足液晶显示面板亮度要求等问题,达到提高亮度、缩小光线分布、避免光传输损失的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

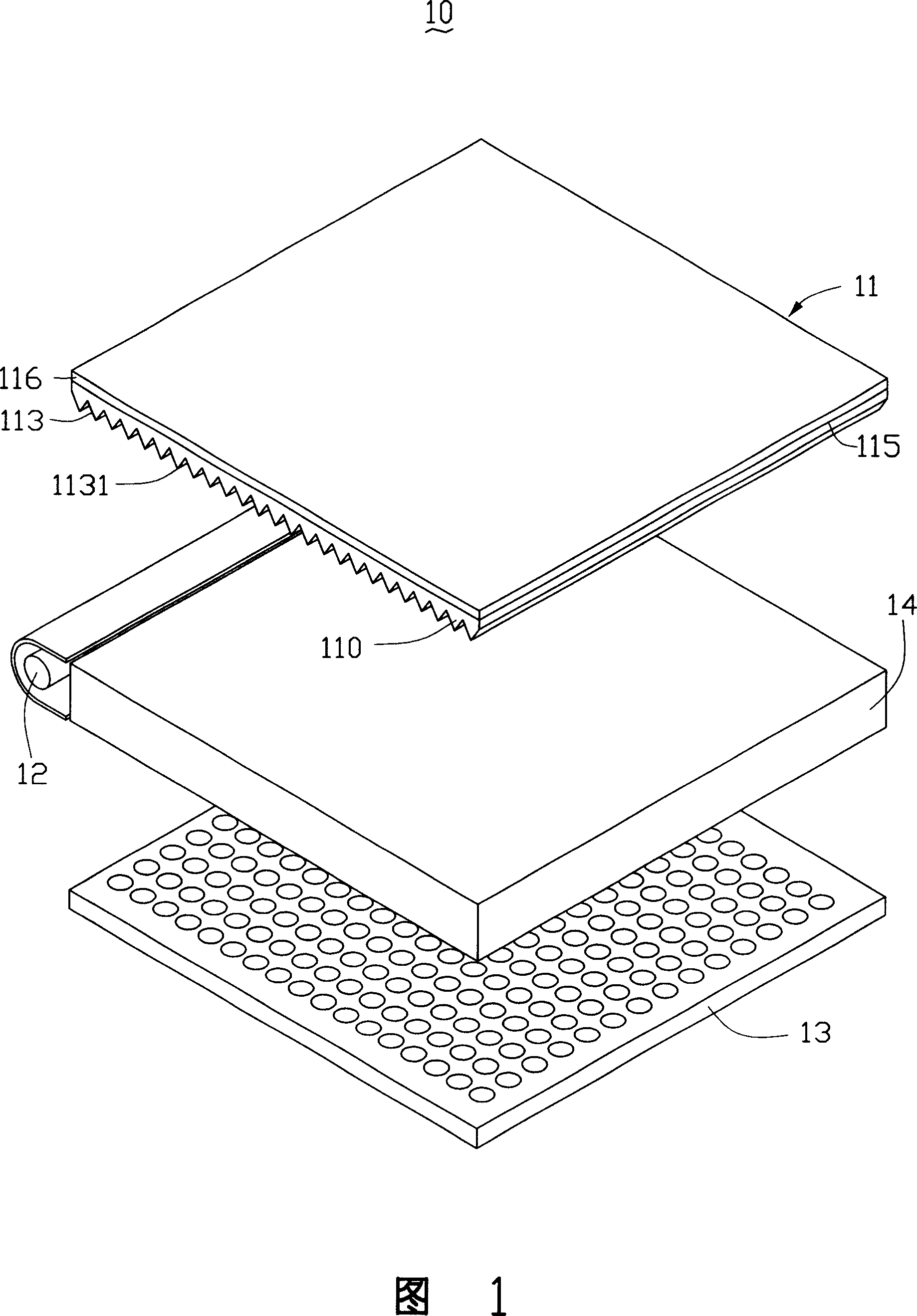

[0016] The prism sheet of the present invention and the backlight module using the prism sheet will be further described in detail below with reference to the drawings and multiple embodiments.

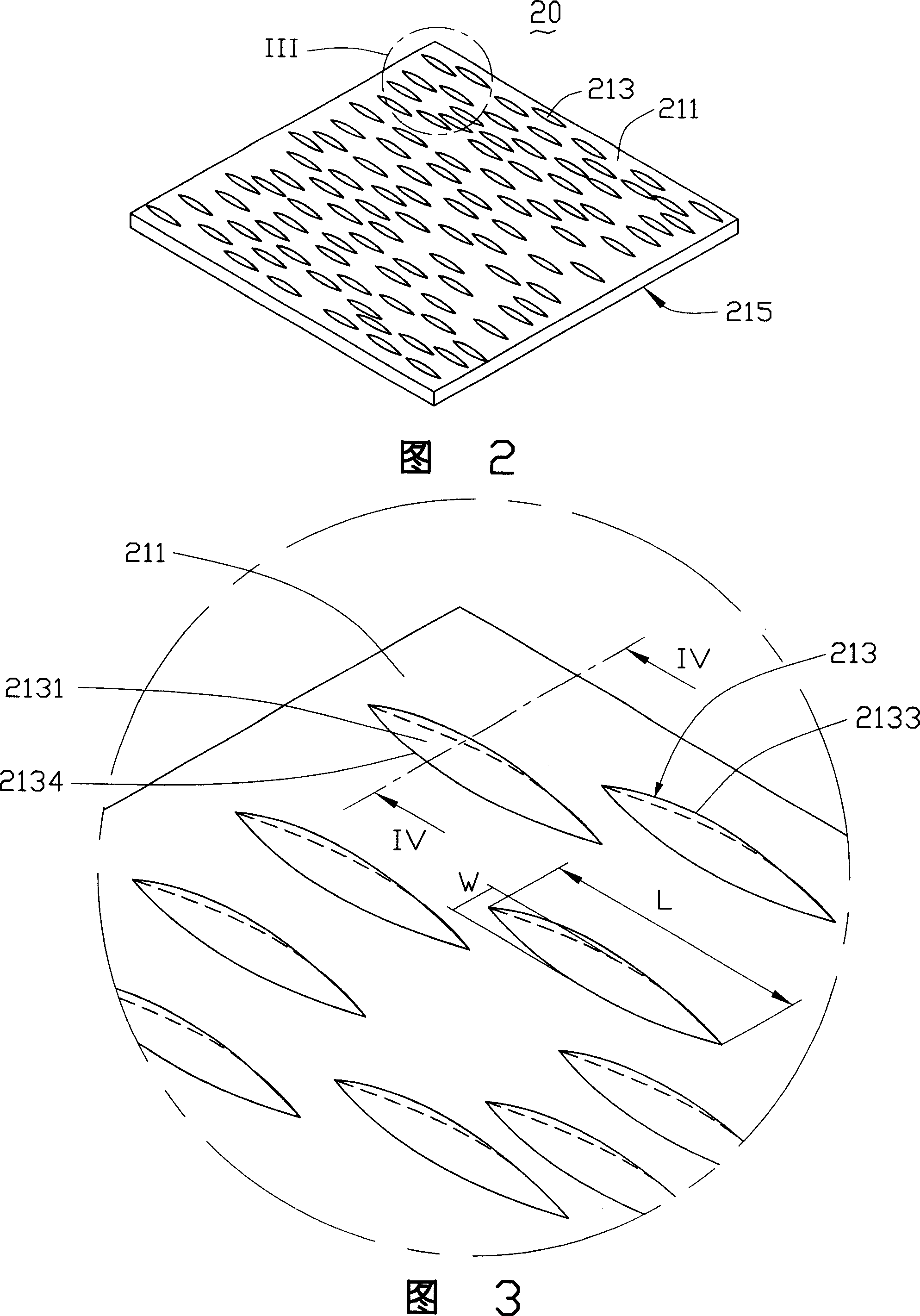

[0017] Please refer to FIG. 2 , which is a preferred embodiment of the prism sheet of the present invention. The prism sheet 20 includes a light incident surface 211 , a light exit surface 215 opposite to the light incident surface, and a plurality of micro protrusions 213 formed on the light incident surface 211 . The light emitting surface 215 is a flat surface.

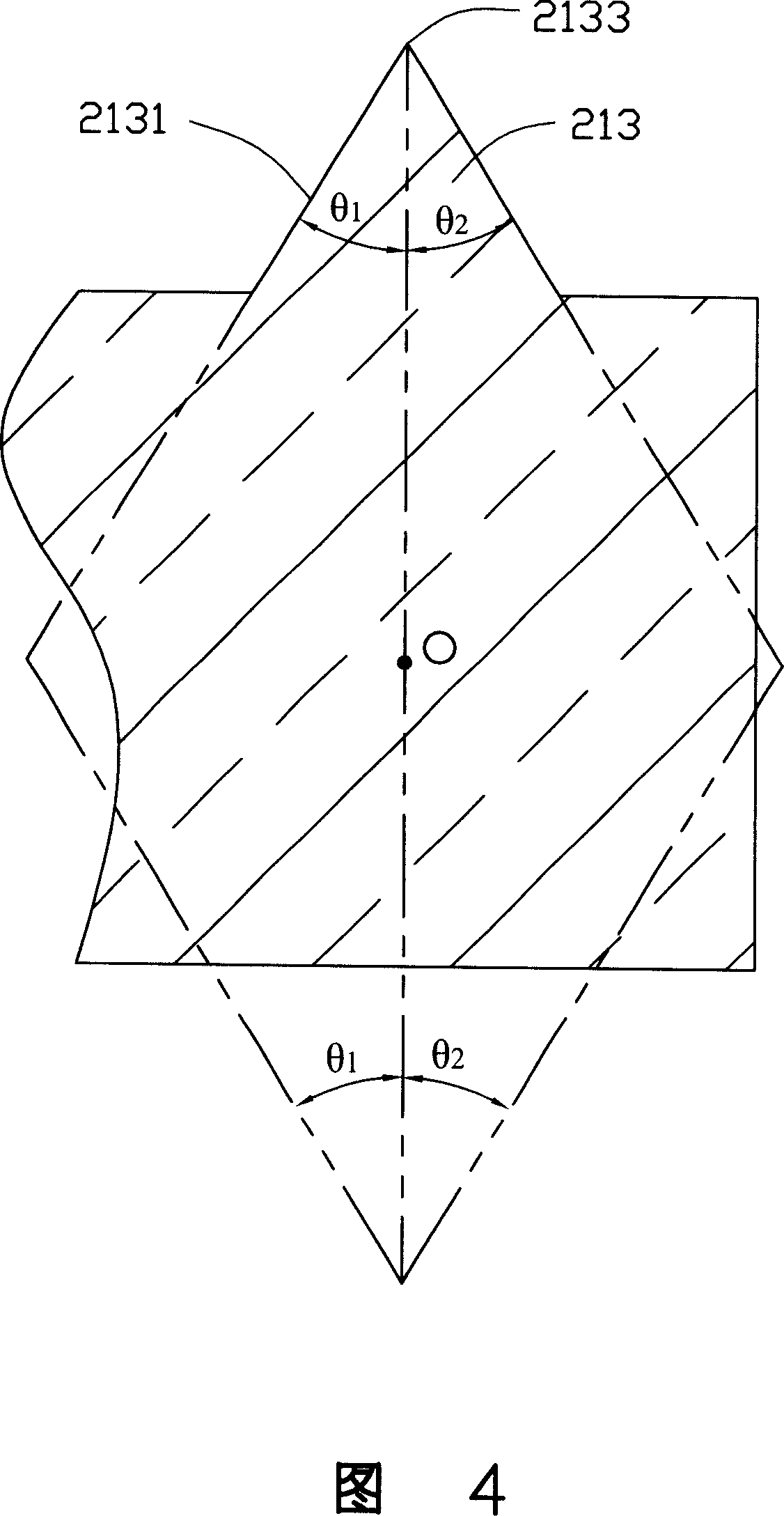

[0018] Please refer to FIG. 3 and FIG. 4 , each micro-protrusion 213 includes two convex sides 2131 and an arc top line 2133 . The circle where the arc top line 2133 is located intersects the light incident surface 211 , wherein the center of the circle is O. The two sides 2131 are partly tapered. The cone shape is a cone with a certain height, with the circle where the arc top line 2133 is located as the base circle. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com