Centrifugal shaping tool

A centrifugal molding and tooling technology, which is applied in the manufacture of tools, ceramic molding machines, ceramic molding cores, etc., can solve the problems of easy interference phenomenon, inconvenient operation, and complex structure of automatic molding centrifugal devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0107] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

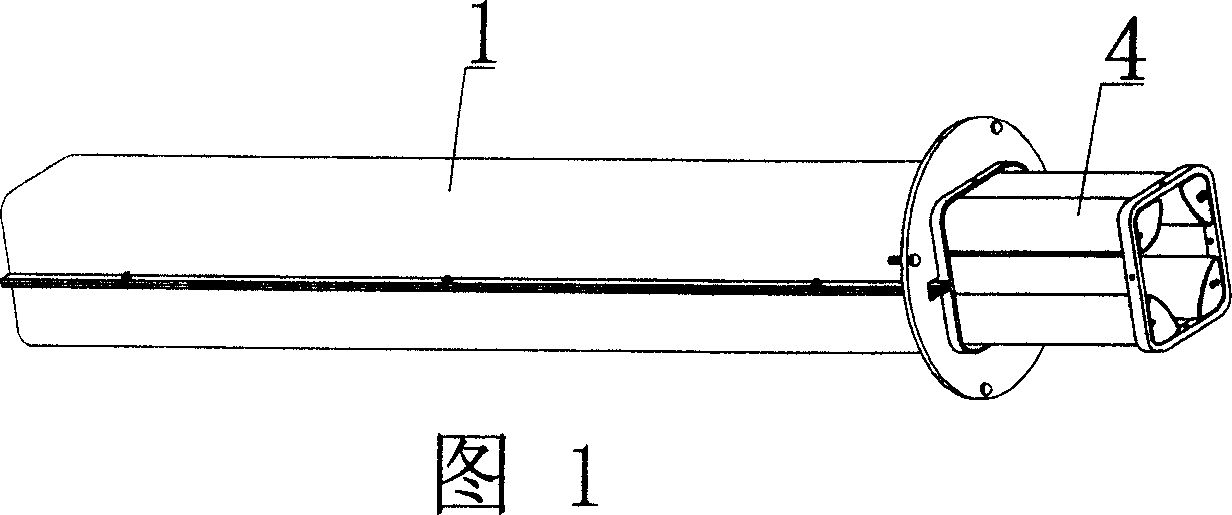

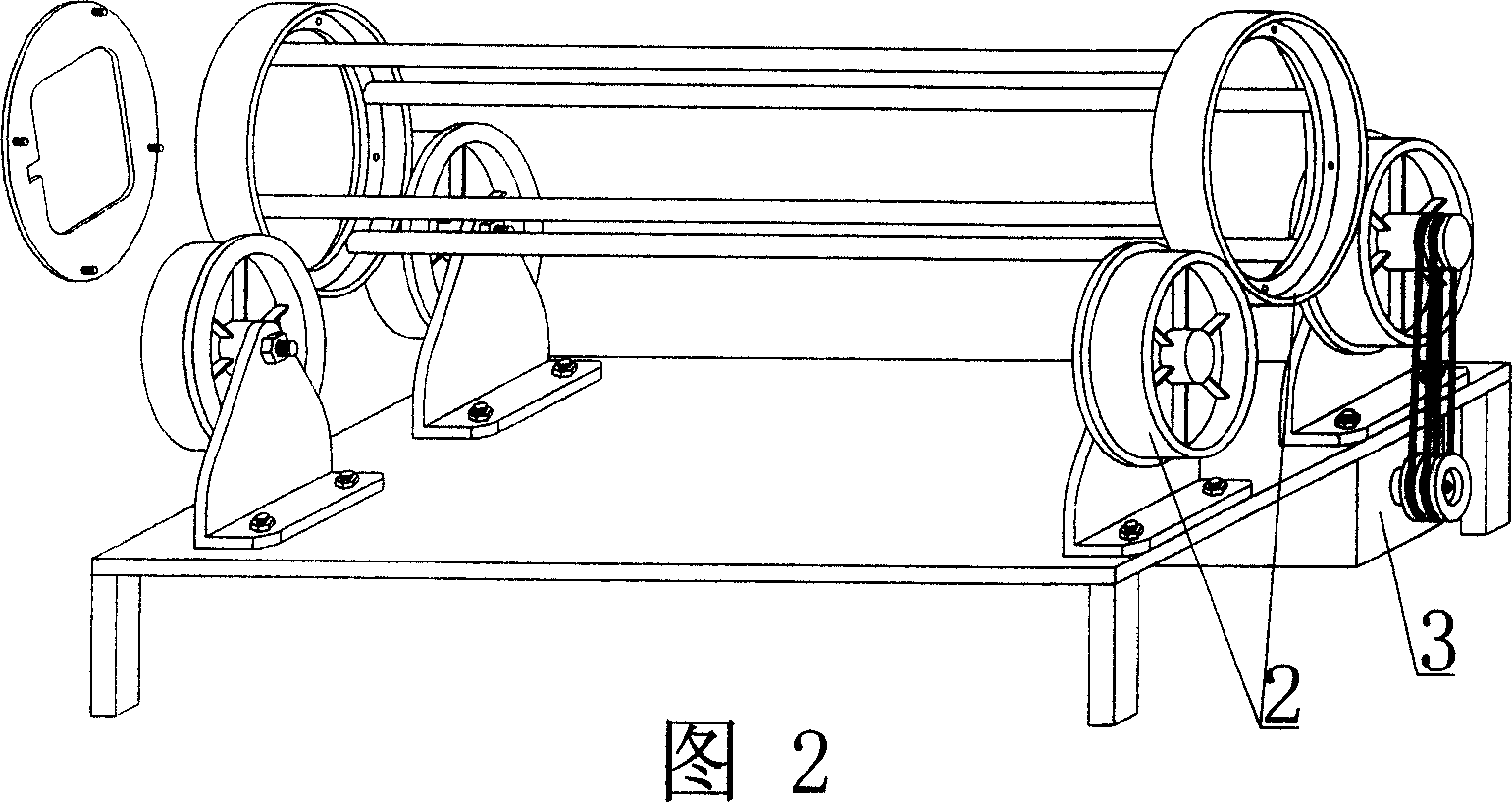

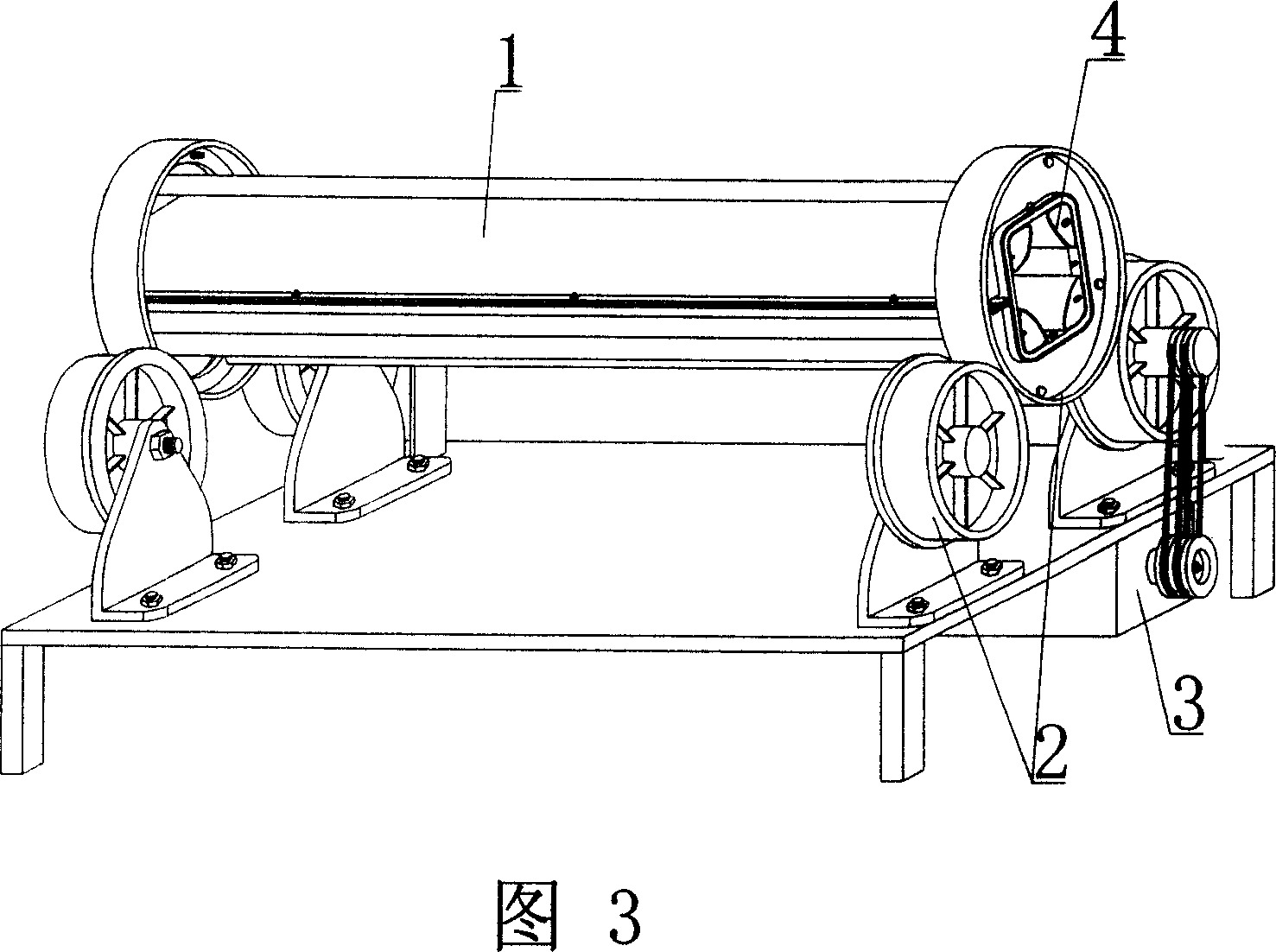

[0108] As shown in the accompanying drawings, the present invention includes a ring-shaped mold 1, a mold support 2, and a centrifugal drive member 3, and is characterized in that the ring-shaped mold 1 has at least one core mold 4 that limits the internal shape of the product. In each accompanying drawing, 1 is an annular tubular mold, 2 is a mold support, 3 is a centrifugal drive member, and 4 is a mandrel. In the following accompanying drawings, those with the same number have the same description. As shown in FIG. 3 , there are four core molds 4 that limit the internal shape of the product in the annular tubular mold 1 . FIG. 1 is a process diagram of the core mold 4 extending into the annular tubular mold 1 ; FIG. 2 is a schematic diagram of the mold support 2 and the centrifugal driving member 3 .

[0109] The present invention is also characteri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com